Tunnel blasting method

A technology of tunneling and cutting holes, which is applied in blasting and other directions, and can solve the problems of large explosion disturbance of tunnel surrounding rock, reducing the integrity of tunnel surrounding rock, affecting the contour surface of blasting excavation, etc., so as to avoid the risk of gas accumulation and facilitate popularization Use, improve the effect of the blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

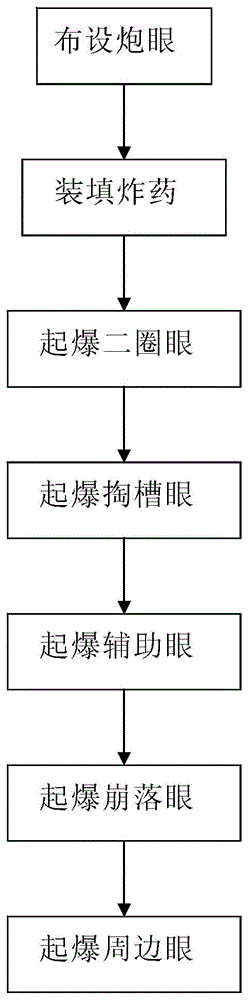

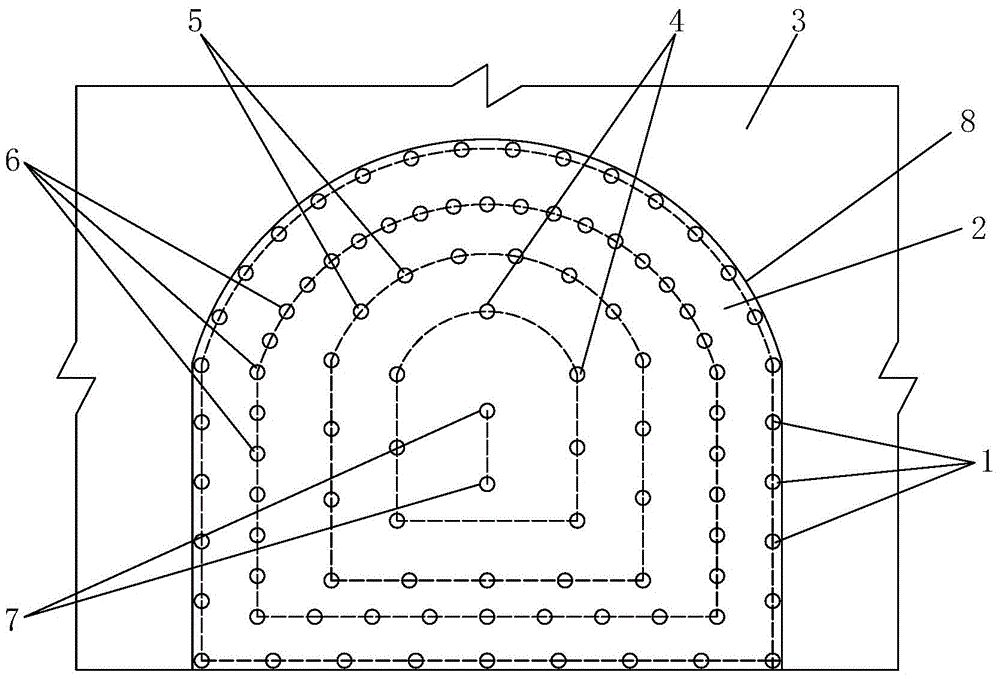

[0032] Such as figure 1 with image 3 A tunnel blasting method shown comprises the following steps:

[0033] Step 1. Laying blastholes: laying a circle of peripheral holes 1 on the tunnel blasting face 2 and close to the tunnel excavation contour line 8, and laying a circle of two holes on the tunnel blasting face 2 and inside the peripheral holes 1. Ring eye 6, on the tunnel blasting face 2 and on the inside of the second ring eye 6, a caving eye 5 is arranged, and on the tunnel blasting face 2 and on the inner side of the caving eye 5, a cutting eye 4 is arranged;

[0034] In this embodiment, when laying blastholes, a drilling jumbo is used to lay out peripheral holes 1 , cutting holes 4 , caving holes 5 and secondary ring holes 6 on the blasting face 2 of the tunnel. Design the spacing of peripheral eye 1, caving eye 5 and cutout eye 4 according to the smooth blasting method. The distance between the two eyelets 6 refers to the peripheral eye 1 or the avalanche eye 5 and...

Embodiment 2

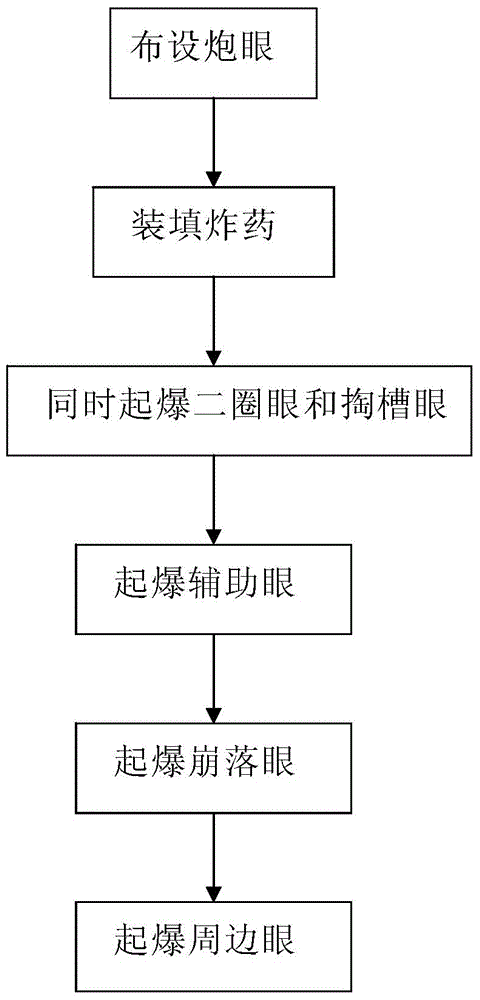

[0047] Such as figure 2As shown, the difference between this embodiment and Embodiment 1 lies in the sequence of detonation in step 3. In this embodiment, the sequence of detonation in step 3 is: first detonate the second ring eye 6 and the cutout 4 at the same time, and then detonate in sequence Avalanche eye 5 and peripheral eye 1. By detonating the second ring hole 6 and the cut hole 4 at the same time, the inter-eye penetration crack formed by the second ring hole 6 in an instant can effectively block the blast stress wave transmitted by the blasting of the cut hole 4, and at the same time, it can shorten the blasting time of all blast holes. Blasting time to avoid the risk of gas accumulation caused by too long blasting time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com