Device for detecting and comparing performance of filters as well as detection method

A detection device and filter technology, which is applied in the direction of measuring devices, scientific instruments, suspension and porous material analysis, etc., can solve the problems of high cost, long detection cycle, uneven quality, etc., and achieve low cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

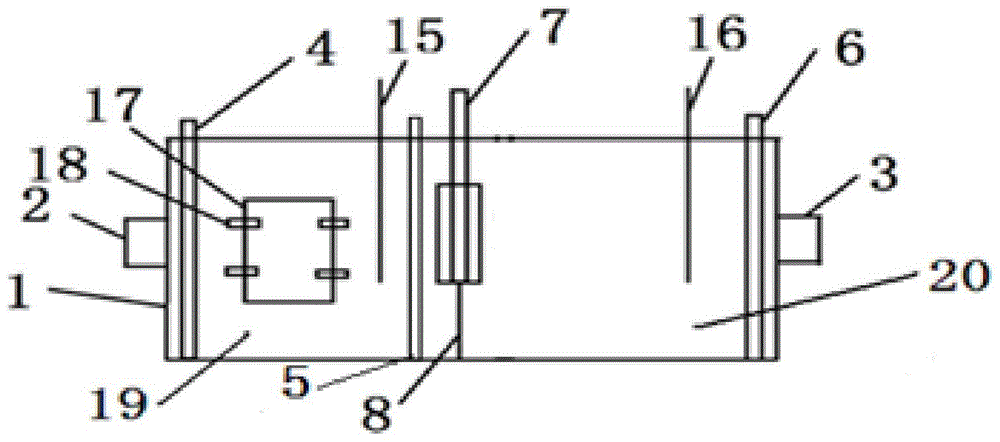

[0044] Take the need to detect the filtering effect of hydrogen sulfide gas treated by the filter as an example.

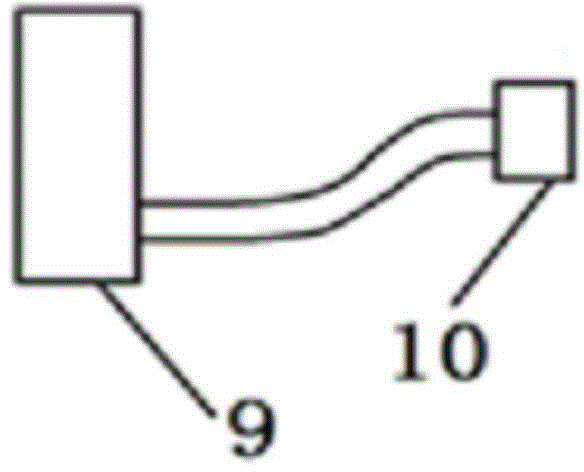

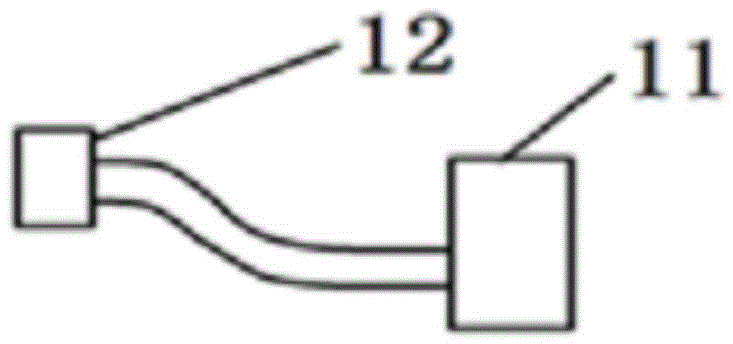

[0045] Connect the devices involved in this application, the hydrogen sulfide gas cylinder is used as the detection source generating device 9, the hydrogen sulfide concentration detector is used as the pre-filtration detector 15 and the post-filtration detector 16, the first sealing plate 4 is opened, and the second sealing plate 5 is dropped , open the gas cylinder, and when the hydrogen sulfide gas fills the detection atmosphere chamber 19 and reaches the specified concentration, close the gas cylinder and drop the first sealing plate 4 . Connect the vacuum pump interface 12 to the detection source discharge port 3, and use the vacuum pump 11 to vacuumize. When the vacuum degree reaches 0.5MPa, drop the third sealing plate 6, remove the vacuum pump 11, and connect the detection source discharge port 3 to the detection source processing device interface. 14. Put...

Embodiment 2

[0047] Take the need to detect and compare the dust filtration effects of two filters as an example.

[0048] Connect the two devices of the present application, the dust raising device is used as the detection source generating device 9, the portable dust detector is used as the pre-filtration detector 15 and the post-filtration detector 16, the first sealing plate 4 is opened, and the second sealing plate 5 is dropped. Turn on the dust raising device, and when the dust fills the detection atmosphere chamber 19 and reaches a specified concentration, turn off the dust raising device and drop the first sealing plate 4 . Utilize the vacuum pump 11 to vacuumize, and when the degree of vacuum reaches 1 MPa, drop the third sealing plate 6, take off the vacuuming device, connect the detection source discharge port 3 to the detection source processing device interface 14, and put water into the detection source processing device interface 14. . Everything is ready, raise the second ...

Embodiment 3

[0050] For example, it is only necessary to compare the dust filtration effects of the two filters without specific test data.

[0051] Connect the two devices of the present application, the dust raising device is used as the detection source generating device 9, without installing the pre-filtering detector 15 and the post-filtering detector 16, the first sealing plate 4 is opened, the second sealing plate falls, and the dust raising device is opened. When the dust is full of the detection atmosphere chamber 19 and the colors of the two filter performance detection devices 1 are consistent, close the dust raising device and drop the first sealing plate. Use the vacuum pump 11 to vacuumize. When the vacuum degree reaches 1MPa, drop the third sealing plate, remove the vacuum device, connect the detection source discharge port 3 to the detection source processing device interface 14, and put water into the detection source processing device 13. Everything is ready, raise the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com