Anti-collision device in longitudinal direction of ultrasonic probe

An anti-collision device, ultrasonic technology, applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., to avoid damage, improve flexibility and accuracy, high flexibility and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples of the present invention are described in detail, and the following examples provide detailed implementation methods and specific operation processes, but the protection scope of the present invention is not limited to the following examples.

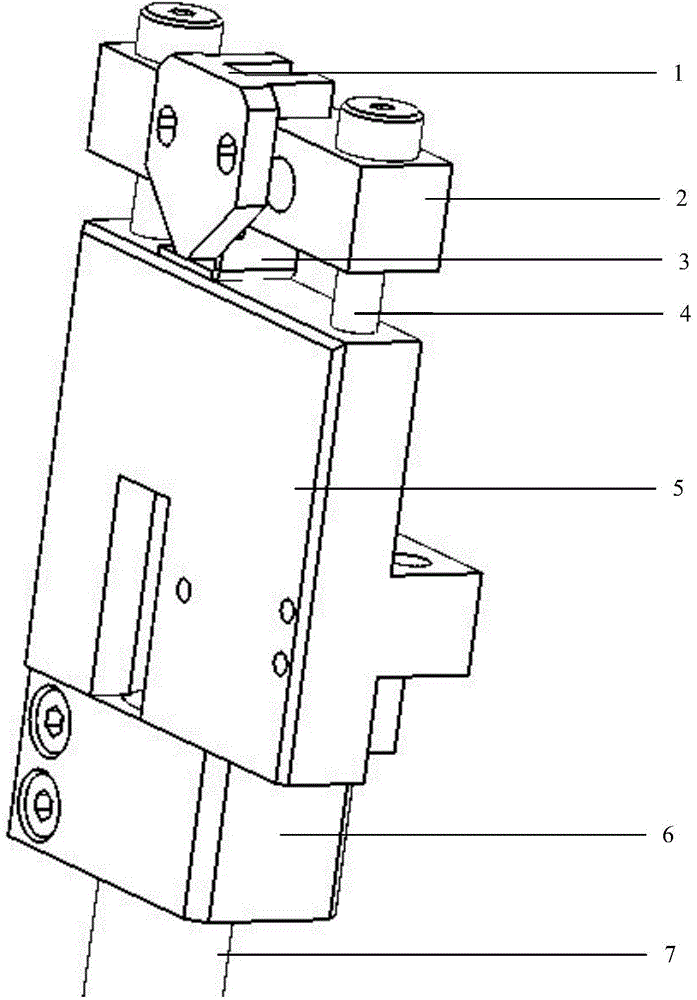

[0019] The specific embodiment of the anti-collision device in the vertical direction of the ultrasonic probe of the present invention is as follows: figure 1 As shown, it includes a photoelectric sensor 1, a bearing bracket 2, an L-shaped anti-collision block 3, an elastic screw 4, an installation adapter plate 5, a probe fixture 6, and a probe 7. Among them, the bearing bracket 2 is connected with the installation conversion plate 5 through the elastic screw 4 (acting as a buffer), the photoelectric sensor 1 is installed in the middle of the bearing bracket 2, and the L-shaped anti-collision block 3 is installed on the upper end of the installation conversion plate 5. The vertical part of the anti-collisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com