Multichannel 2x2 photoswitch

An optical switch and multi-channel technology, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems that the optical crystal coating layer is easily oxidized or polluted, affects the working life of the optical switch, and changes in the insertion loss of the optical path, and achieves low production costs. , good sealing performance and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

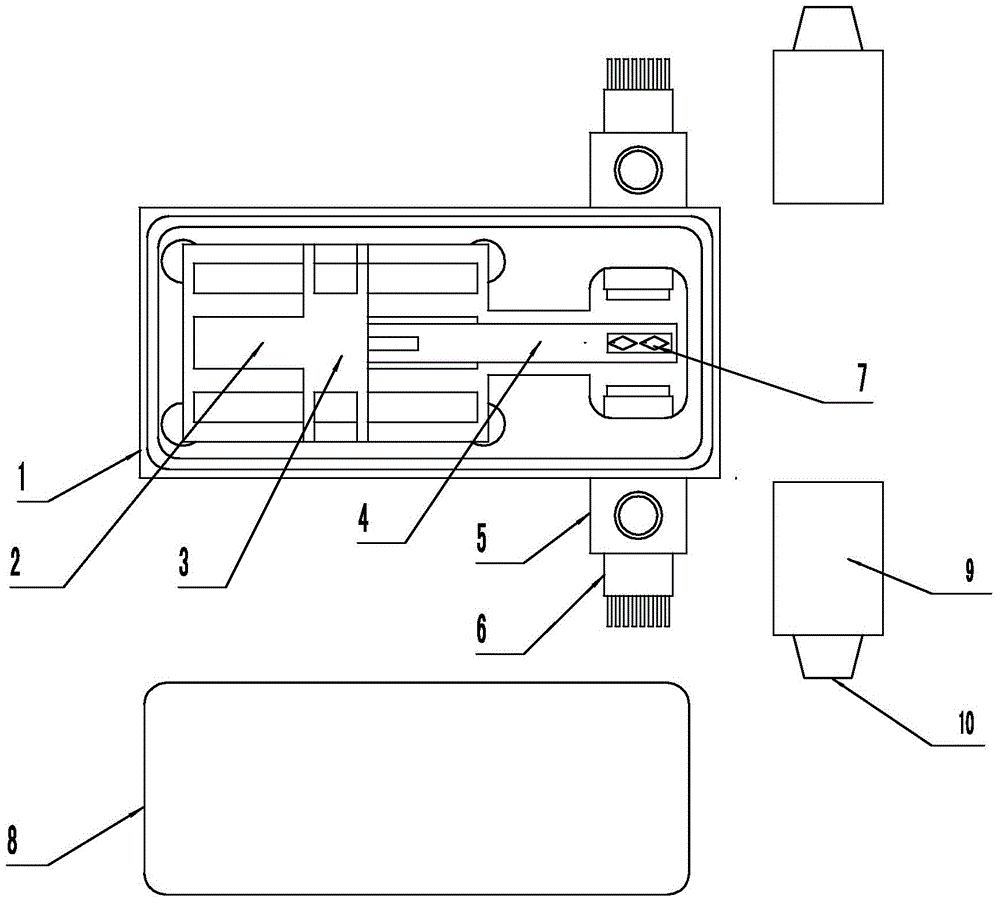

[0019] The embodiment of an 8-channel 2×2 optical switch will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, in the embodiment of the 8-channel 2X2 optical switch, the bottom box 1 has a cuboid inner cavity, the relay 3 is embedded in the bottom of the inner cavity of the bottom box 1, the bottom of the bottom box 1 has pin holes, and the pins of the relay 3 are from the bottom The pin hole of box 1 sticks out, connect the drive wire. There is respectively a plug hole on the two opposite sides of the bottom box 1, and the plug holes on each side are respectively fixedly connected to the plug pipe 5 outside the side, and the centerlines of the plug pipe 5 on the two sides are in a straight line, and the The straight line is perpendicular to the side of the bottom box 1 where the plug pipe 5 is installed. Two 8-core optical collimators 6 are respectively inserted into the plug tube 5 on one side. After the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com