Water-cooled permanent magnet energy-saving speed regulating motor

A speed-regulating motor and water-cooling technology, applied to electrical components, electromechanical devices, electric components, etc., can solve problems such as high maintenance costs, complicated speed-regulating technology, and poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

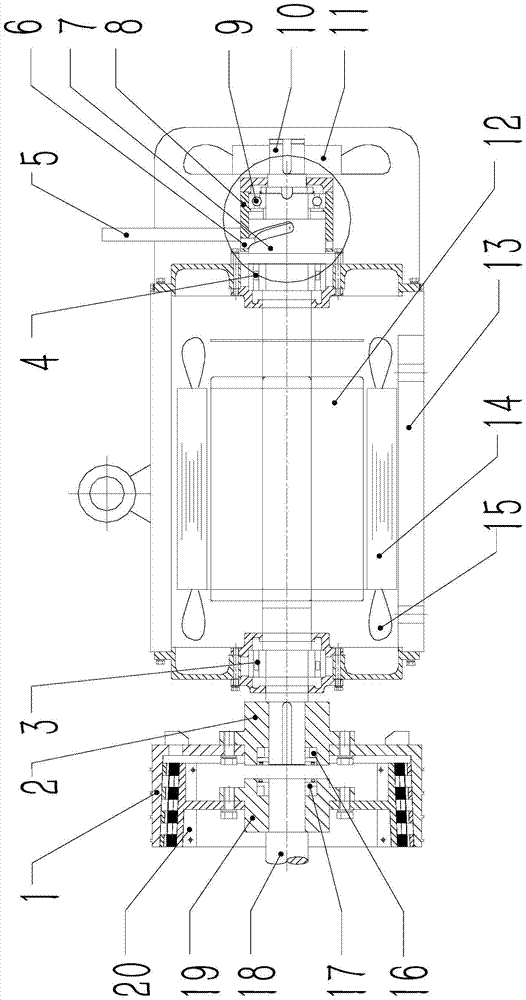

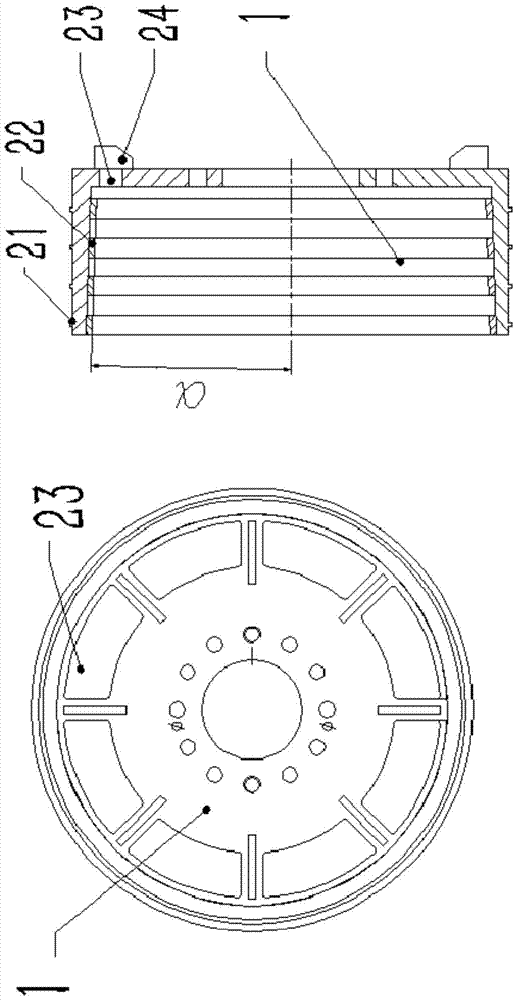

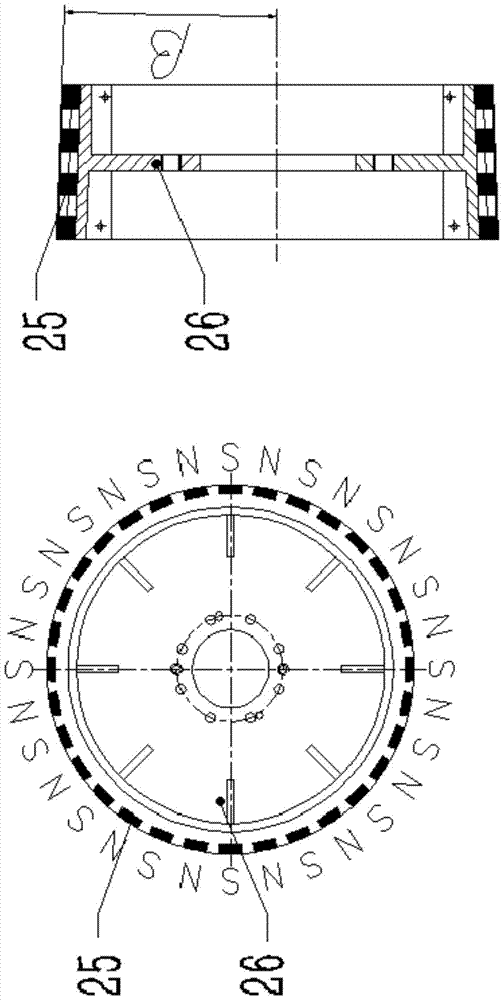

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the water-cooled permanent magnet energy-saving speed-regulating motor includes a motor housing, a motor rotor and a motor stator located in the motor housing, a motor rotor shaft that is coaxial with the motor housing and passes through the motor housing, The speed regulating assembly fixedly arranged at the left end of the motor housing to drive the axial movement of the motor rotor, the transient magnetic rotor fixedly arranged at the left end of the motor rotor shaft, the permanent magnetic rotor located in the transient magnetic rotor and fixedly connected with the load shaft, A cooling assembly for dissipating heat from the transient magnetic rotor; the load shaft is coaxial with the motor rotor shaft; the permanent magnet rotor is force-transmittingly connected to the transient magnetic rotor in the circumferential direction and is slidingly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com