High compatibility igbt driver

A driving device and driving resistor technology, which is applied to output power conversion devices, electrical components, electronic switches, etc., can solve the problems of poor compatibility and reliability of IGBT driving circuits, and achieve enhanced anti-interference performance, high driving power, and compatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

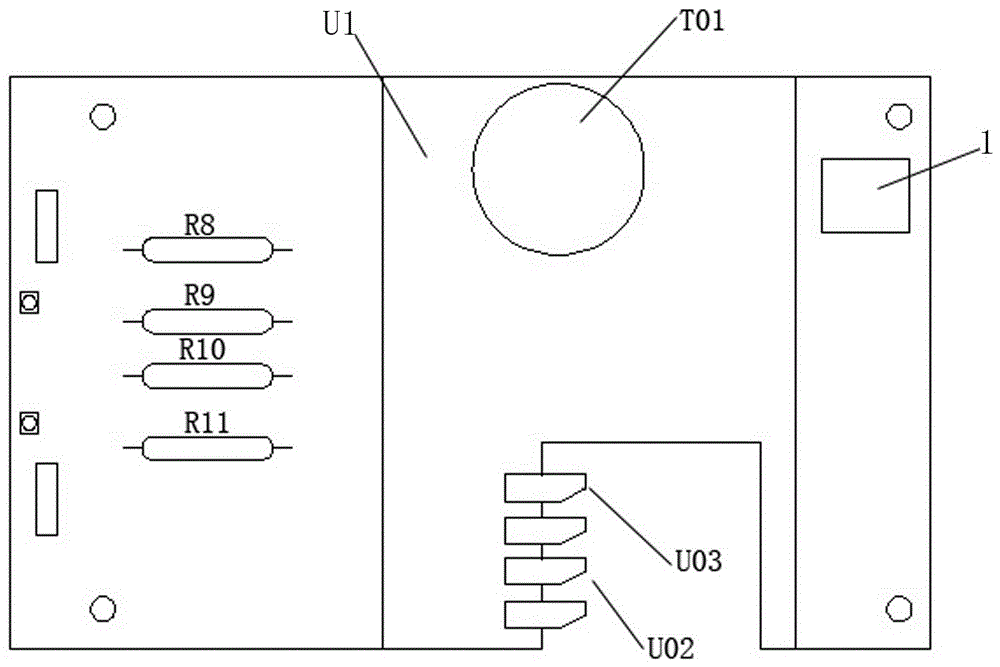

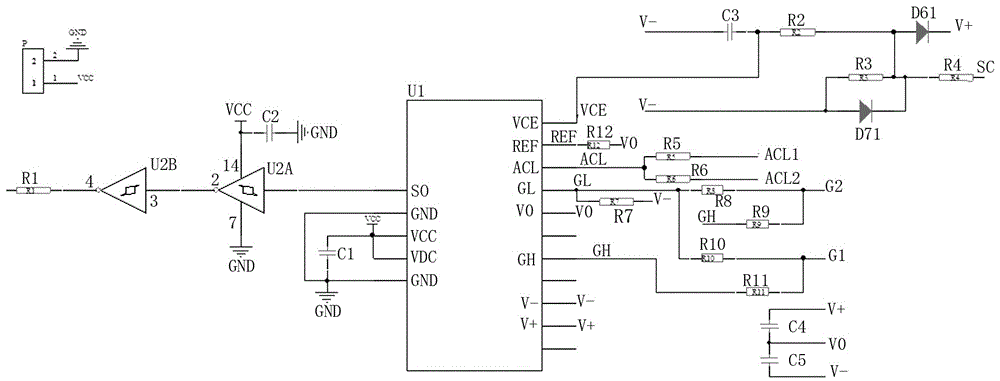

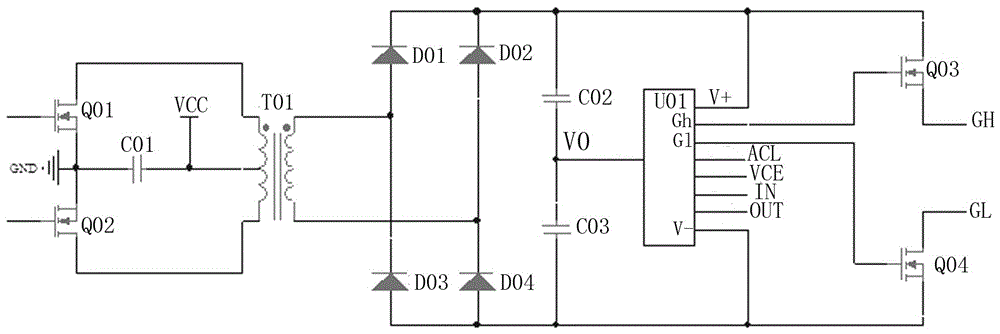

[0034] A highly compatible IGBT driving device, comprising a data acquisition control circuit; the data acquisition control circuit includes an internal circuit U1 and drive resistors R8, R9, R10, R11; said U1 is provided with SO, GND, VCC, VDC, VCE , REF, ACL, GL, V0, GH, V+, V- ports; the SO port of U1 is connected to the resistor R1 through the Schmitt trigger converter U2; U2 includes two channels U2A and U2B, and the fourteenth pin of U2A is connected to The VCC terminal of U1 is connected to the ground through the capacitor C2, and the seventh pin of U2A is grounded; the VCC terminal of U1 is grounded through the capacitor C1; the VCC terminal of U1 is grounded through the capacitor C1, and the VCC terminal is connected to the VDC terminal; the VCE of U1 One end is divided into two circuits, one is connected to diode D61 through resistor R2, the negative pole of D61 is connected to V+ terminal of U1, and the other is connected to V- terminal of U1 through capacitor C3; on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com