Sunlight greenhouse adopting pluggable heat insulation wall body

A technology for solar greenhouses and thermal insulation walls, applied in the field of solar greenhouses, can solve a large number of construction waste, land pollution and other problems, achieve the effect of protecting the environment and land, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

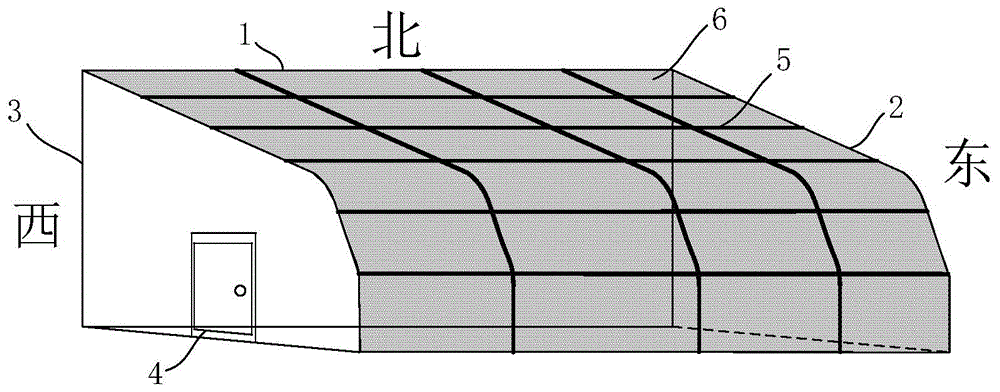

[0031] The solar greenhouse of the present invention comprises a north wall body 1, an east wall body 2, a west wall body 3, a plug-in door 4, a shed film pole 5 and a shed film 6, such as figure 1 As shown; the north wall 1, the east wall 2 and the west wall 3 all adopt plug-in thermal insulation walls, and have a wall structure composed of two types of splicable wall modules 7, and are used to install the shed film The top modules 8 of the struts 5 are spliced together;

[0032] Wherein, the concrete structure of wall body module 7 of 2 kinds of structures is as follows:

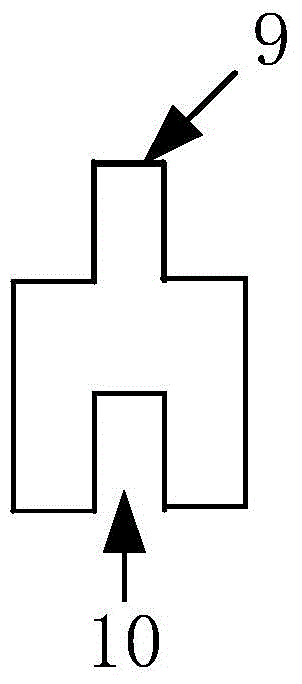

[0033] The structure-wall module 7 is used as an auxiliary module, which is a rectangular integrated structure with a plug joint 9 on the top surface and a plug slot 10 on the bottom surface, such as figure 2 shown;

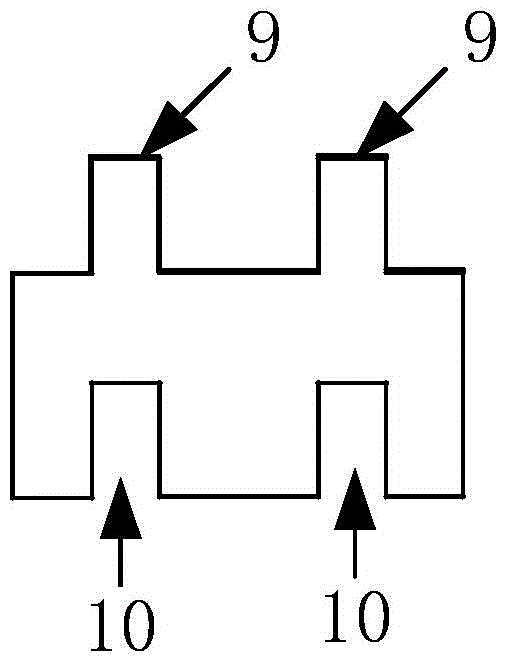

[0034] Structure two wall module 7 is the main module, which is an integral structure formed by two structure one wall modules 7 left and right symmetrical, and the sides are connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com