A kind of sweet corn grain production line and production process

A technology of sweet corn kernels and production lines, applied in the fields of preservation of seeds by freezing/cooling, food science, etc., can solve the problems of low yield, low labor efficiency, high energy consumption, etc., so as to achieve no loss of nutrients, reduce labor, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

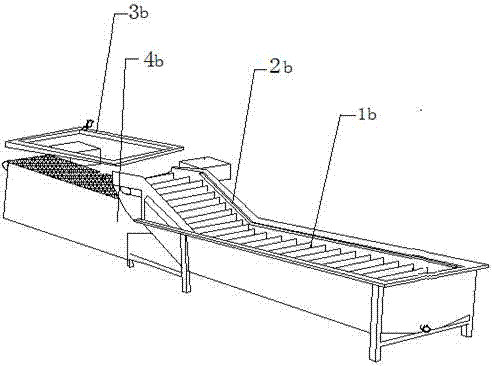

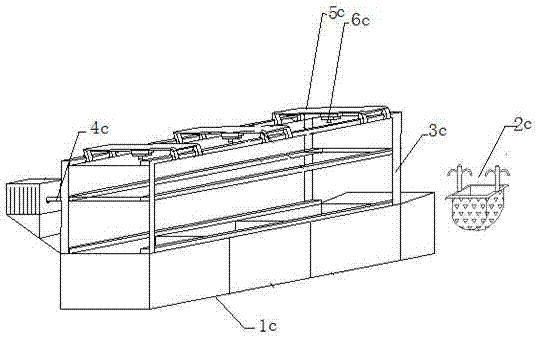

[0037] Such as Figure 1 to Figure 6 The sweet corn kernel production line shown includes the withering system, peeling machine, thresher, sweet corn kernel sorting device, rinsing machine for sweet corn kernel processing, and blanching device for sweet corn kernel processing arranged in sequence according to the material conveying direction , cooling system, draining device for sweet corn kernel processing, quick-freezing system, sweet corn kernel selection mechanism, final metal detection mechanism for sweet corn kernel processing, packaging mechanism and metal detector; due to withering system, peeling machine, thresher, Cooling system, quick-freezing system, packaging mechanism and metal detector; the processing production line in the prior art is relatively complete, and will not be repeated here;

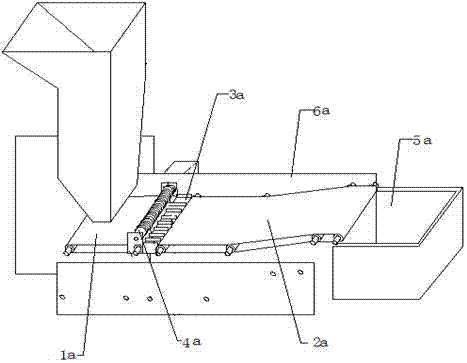

[0038] Described sweet corn kernel evenly spreads sorting device and comprises the first conveyer belt 1a parallel to the ground, and the second conveyer belt 2a that is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com