Method and system for realizing one-ladle-system rotation and production buffer of hot metal ladles

A molten iron tank and canning technology, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of inconsistent direction of the mouth of the molten iron tank, achieve high economic and social benefits, high operation rate, and satisfy The effect of heat turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

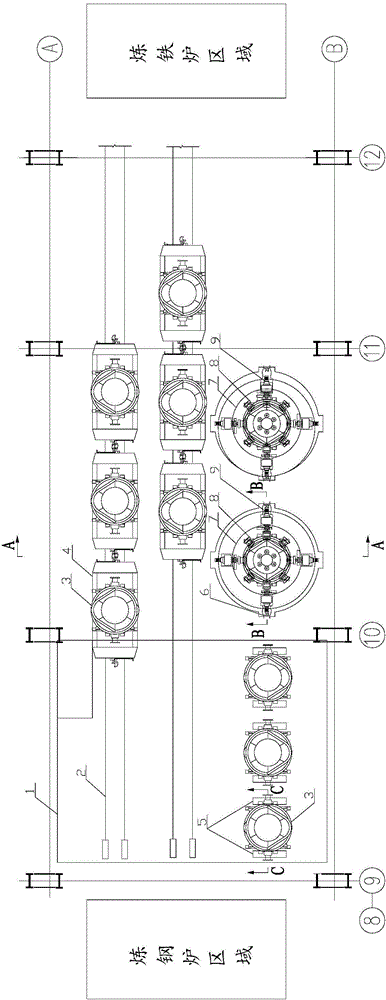

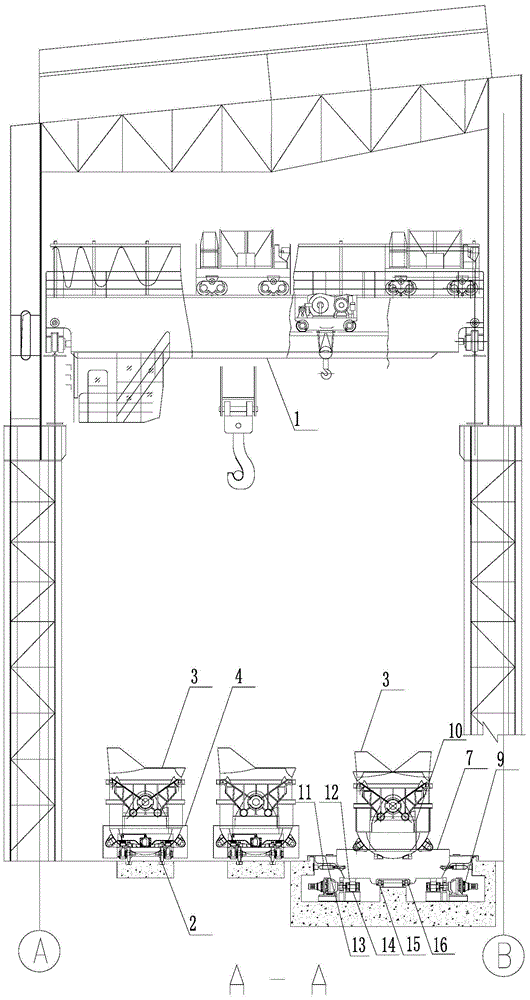

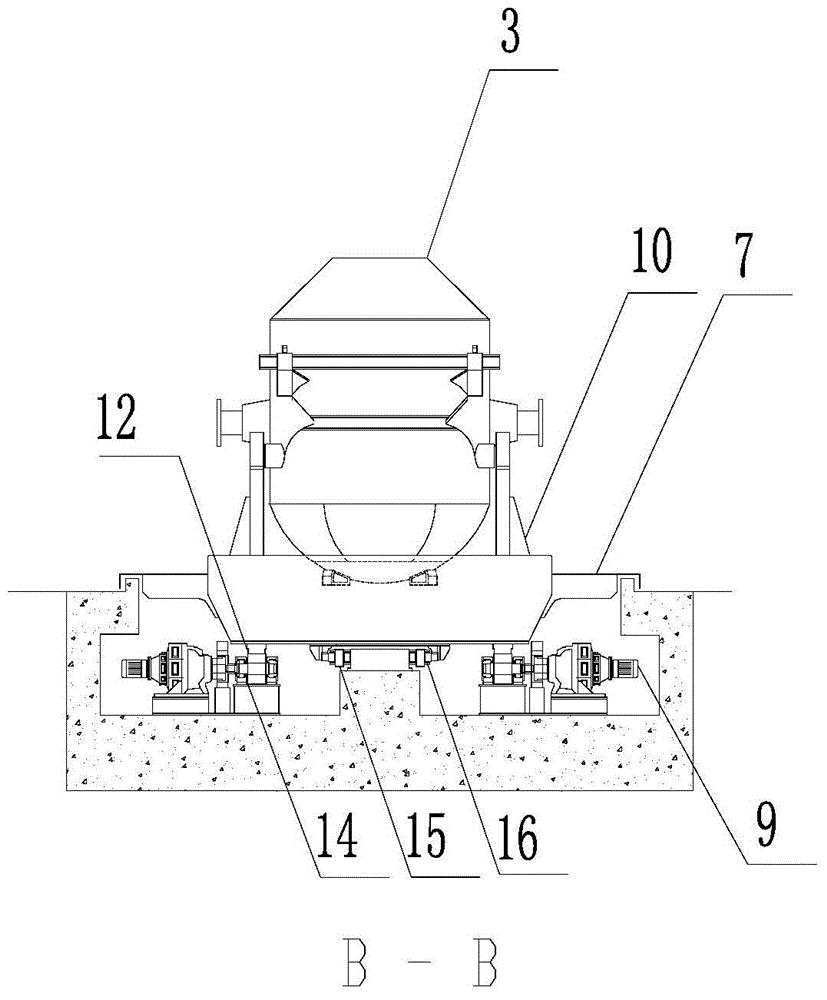

[0032] This embodiment realizes the "one-pot system" molten iron tank rotation and production buffer system, including two sets of molten iron tank rotary table devices and a crane arranged above the molten iron tank rotary table device, wherein

[0033] The molten iron tank turntable device includes a molten iron tank turntable, a turntable drive device is arranged under the hot iron tank turntable to drive the hot iron tank turntable to rotate, and is arranged on the hot iron tank turntable, accommodating all The molten iron tank seat frame of the molten iron tank, and the rotary table positioning device that limits the molten iron tank rotary table to the working starting position and the working target position of the molten iron tank rotary table;

[0034] The crane lifts the molten iron tank to the turret of the molten iron tank, and the molten iron tank platform rotates to the working target position, and the positioning device is used for positioning, and the crane lift...

Embodiment 2

[0038] Such as Figures 1 to 4 As shown, the present embodiment realizes the "one-pot system" molten iron tank rotation and production buffer system, including at least two sets of molten iron tank rotary table devices and a crane 1 arranged above the molten iron tank rotary table device, wherein

[0039] The molten iron tank turret device includes a molten iron tank turret 10, a turret driving device that drives the molten iron tank turret to rotate under the molten iron tank turret, is arranged on the molten iron tank turret, accommodates The molten iron tank seat frame of the molten iron tank, and the rotary table positioning device that limits the rotary table of the molten iron tank to the working start position and the working target position of the molten iron tank rotary table;

[0040] This embodiment also includes a floor stand 5 for the molten iron tank that is arranged in the feeding span to reduce the impact of the molten iron tank on the floor of the workshop.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com