Self-elevating platform pile leg mounting method

A self-elevating platform and installation method technology, applied to sheet pile walls, water conservancy projects, artificial islands, etc., can solve problems such as low work efficiency, long closing time of platform pile legs, and influence of sea conditions, so as to improve production efficiency and shorten Production cycle, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

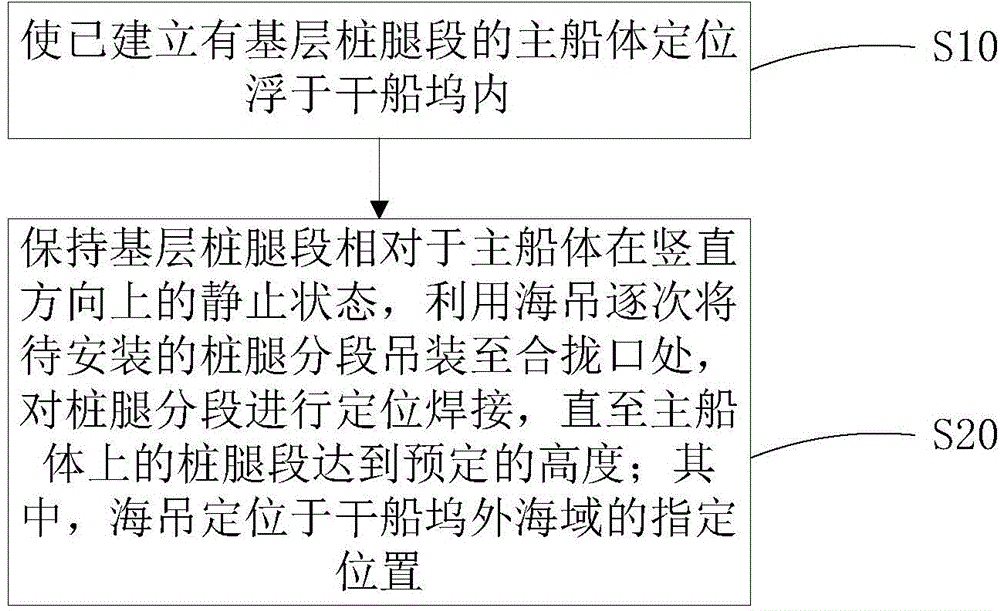

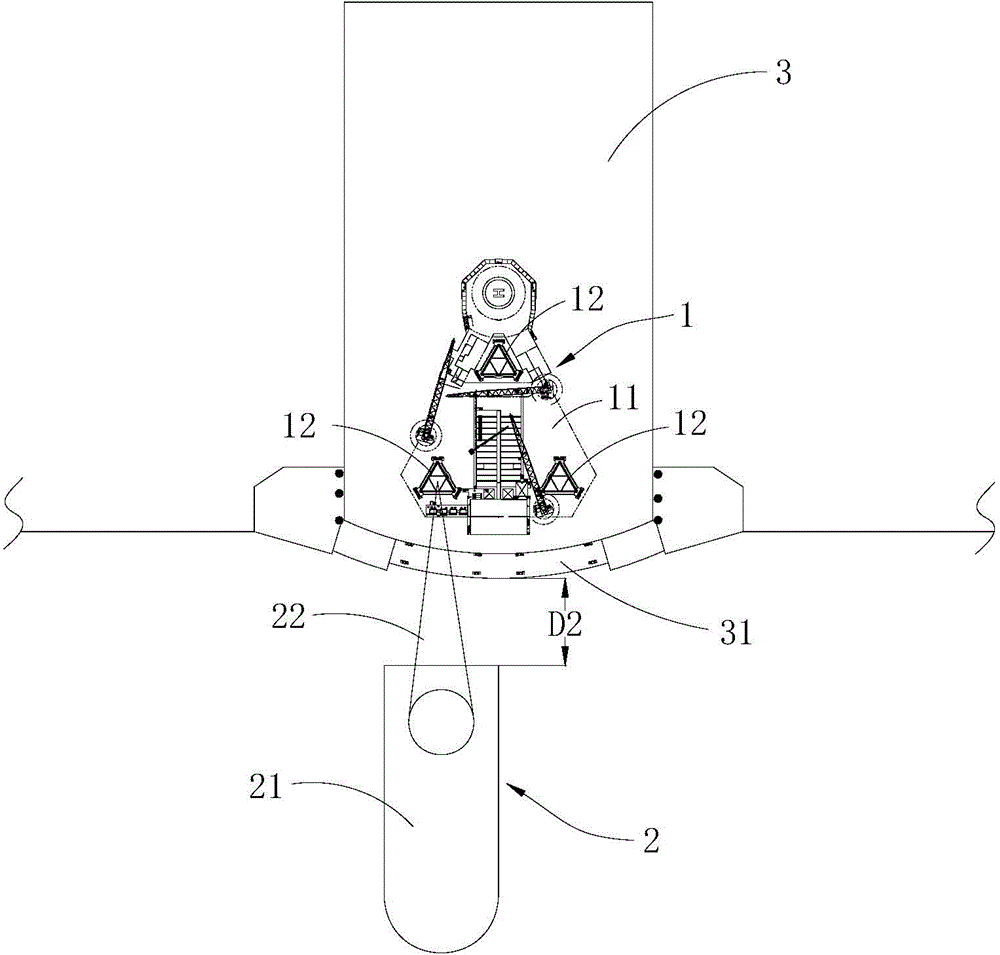

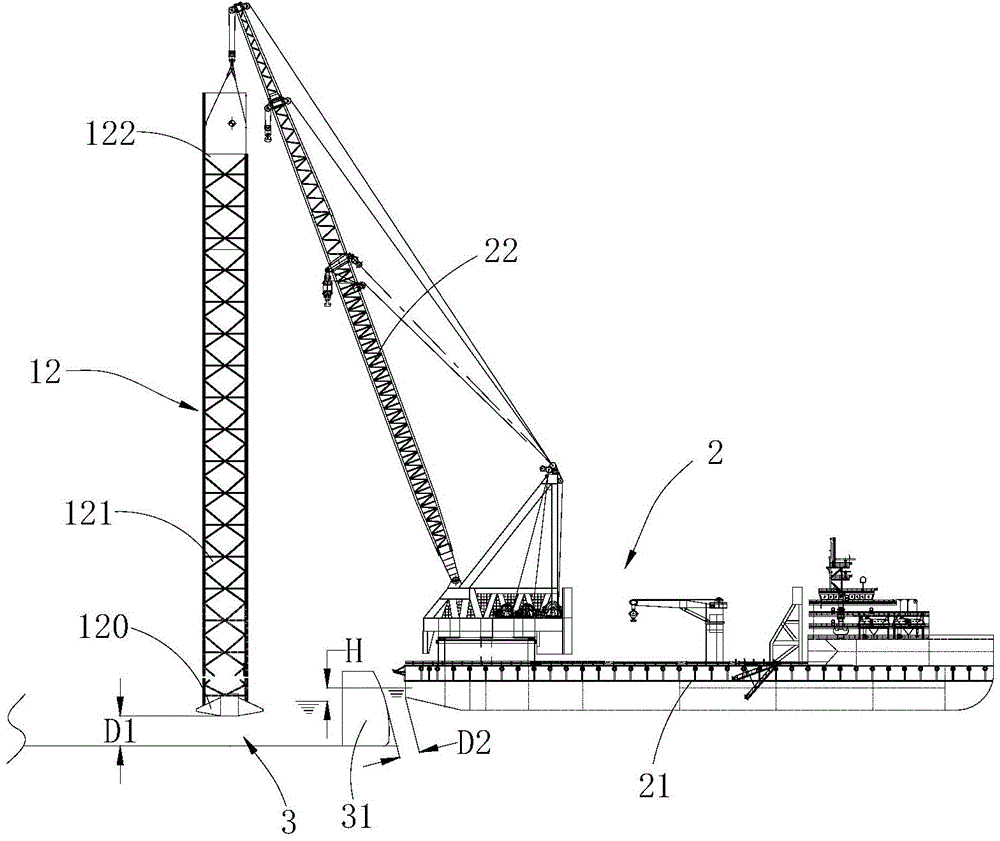

[0040] The invention provides a method for installing the legs of a self-elevating platform, wherein, such as figure 2 As shown, the jack-up platform 1 includes a main hull 11 and legs 12 that can be raised and lowered relative to the main hull 11. As with the current common jack-up platform structure, the jack-up platform 1 has three legs 12 , the legs 12 are arranged in an equilateral triangle on the main hull 11 . Method of the present invention promptly solves the installation problem of pile leg 12, refer to figure 1 , the method mainly includes s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com