Draining and atomizing throttling device

A choke and mandrel technology, which is used in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high cost, insignificant effect, and no universal applicability, and achieves low cost and flexible design. , the effect of saving gas layer energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

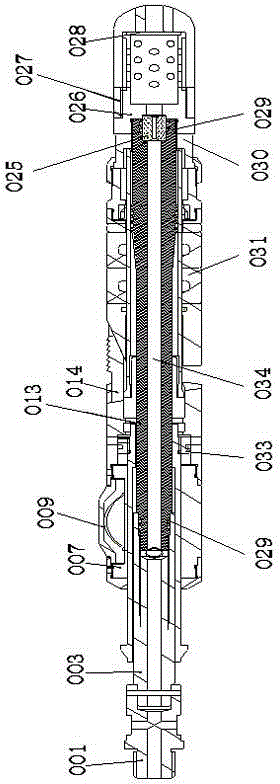

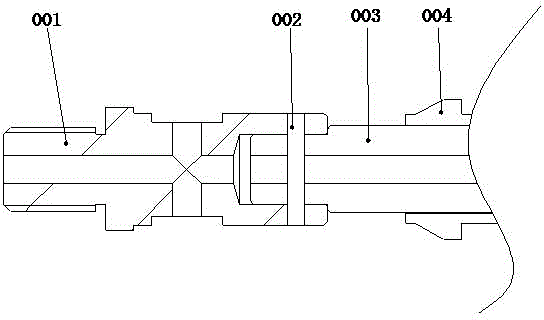

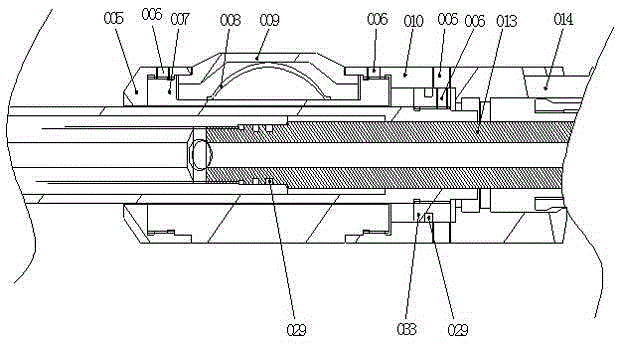

[0042] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the drainage atomization restrictor disclosed in this embodiment includes a structural main body 034, and the two ends of the structural main body 034 are respectively provided with a fixedly connected upper joint 001 and a sand-proof seat 026. The structural main body 034 is composed of a core Rod, slip 014, centralizer 007 and helical tooth cap 020; wherein, the core rod includes an upper core rod 003 and a lower core rod 013, and the slip 014 is embedded and fixed by setting a slip seat, and the The slip seat is composed of an upper slip seat 010 and a lower slip seat 015. The centralizer 007 is pressed down and fixed with a centralizer piece 009 and a centralizer piece spring 008 clamped therein. The tooth cap seat 022 is embedded and fixed, and the upper side of the helical tooth cap 020 is provided with a helical tooth upper pressure cap 019, and the side of the joint of the sand prevention seat 02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com