Vehicle electronic mechanical brake actuator

A mechanical and actuator technology, which is applied in the direction of brake actuators, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of complex structure and pipeline layout, increased difficulty of assembly and maintenance, and increased hydraulic pressure to achieve heat dissipation And the effect of convenient layout, compact structure and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

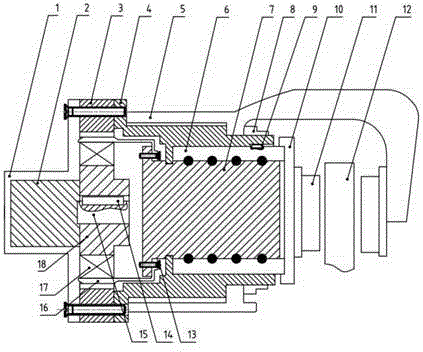

[0017] A vehicle electromechanical brake actuator structure, such as figure 1 shown.

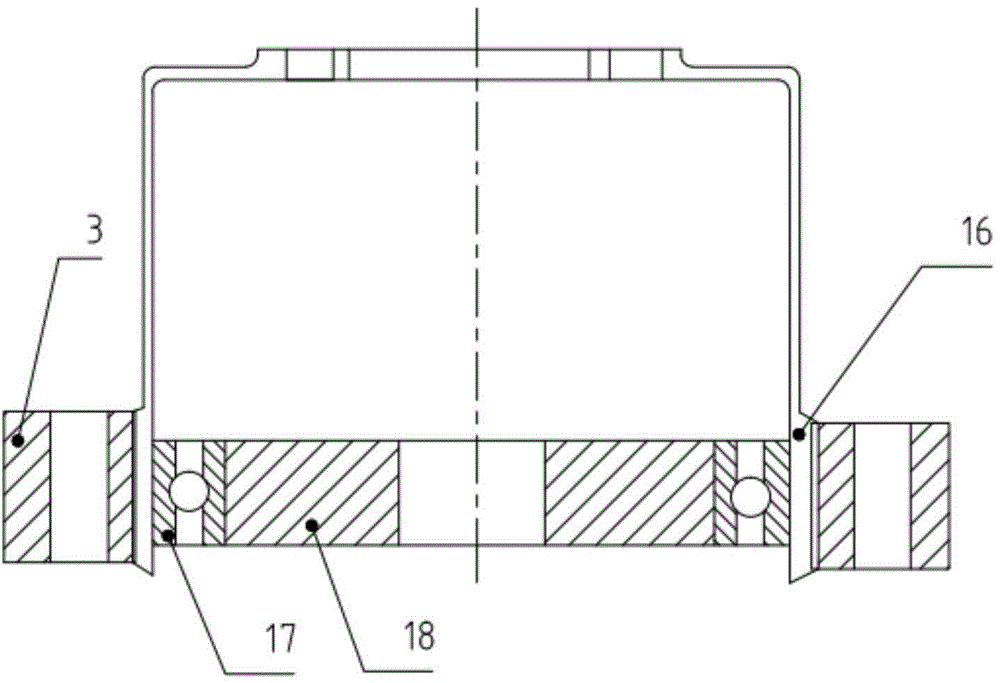

[0018] The power source is the motor 2 encapsulated in the motor outer shell 1, the motor 2 is a DC brushless motor, the motor outer shell 1 is connected with the harmonic reducer rigid wheel 3 and the bracket 4 through fastening screws, and the motor outer shell 1 is connected with the harmonic The bolt holes of the rigid wheel 3 of the wave reducer are through holes without threads, while the bolt holes on the bracket 4 are through holes with threads. The bracket 4 is fixedly connected with the brake caliper body 5 through a lock nut 8 .

[0019] The power of the motor 2 is transmitted to the harmonic reducer through the motor shaft 15, wherein the motor shaft 15 is directly connected with the harmonic generator 18 of the harmonic reducer through the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com