Converter valve thyristor level damping loop parameter testing device and method

A thyristor-level, parametric testing technology, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of reduced test accuracy, inaccurate test results, etc., to achieve convenient operation, simple structure, Test the exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

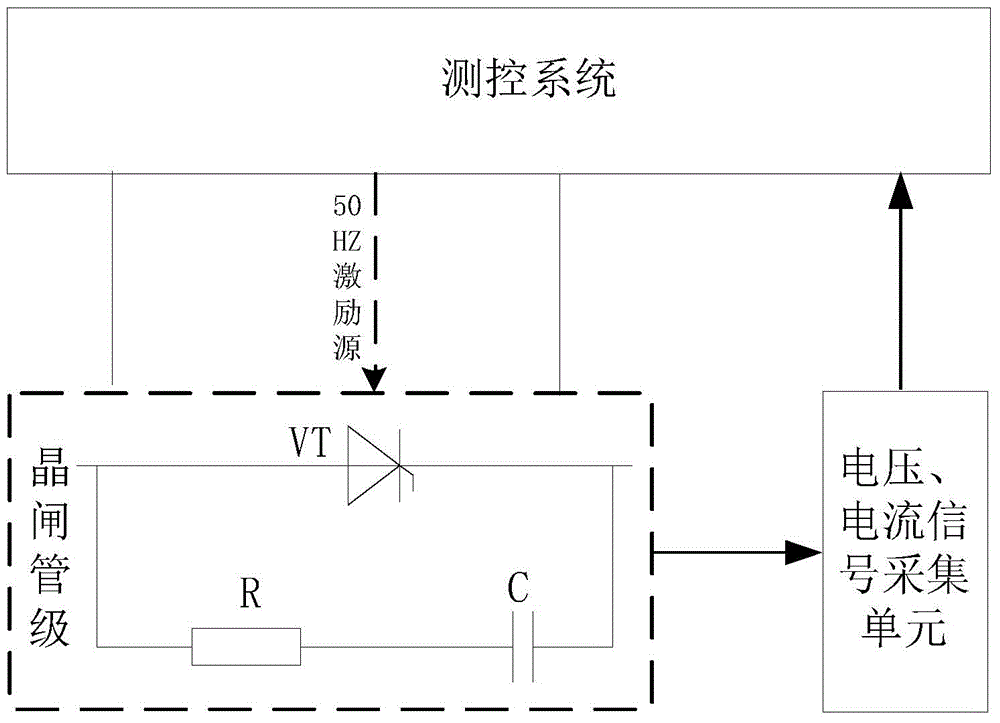

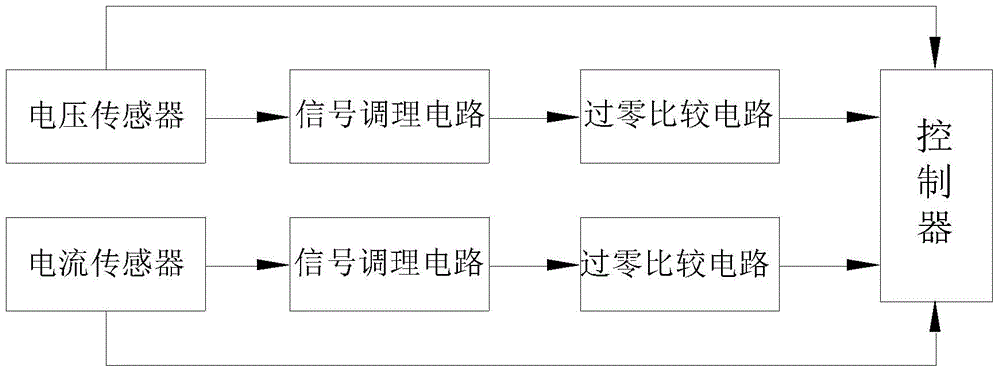

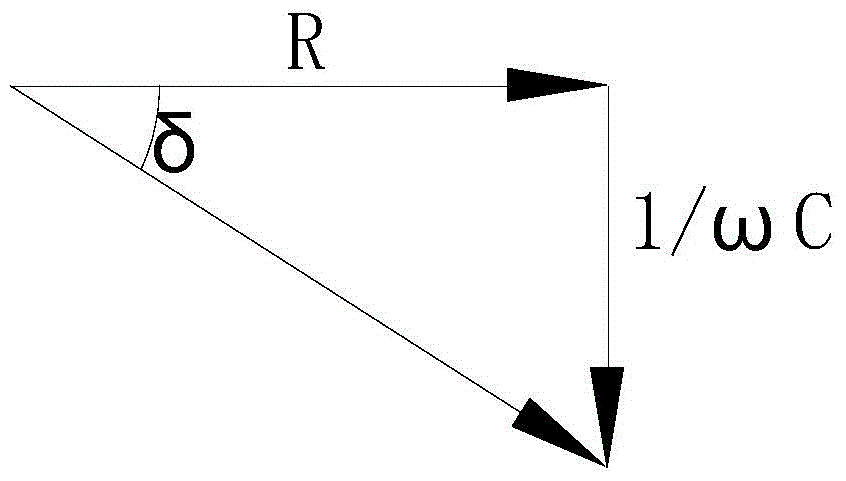

[0021] Such as figure 1 Shown is the schematic block diagram of the thyristor stage damping circuit parameter testing device of the converter valve of the present invention. It can be seen from the figure that the thyristor stage to be tested includes a thyristor VT and a damping circuit composed of a resistor R and a capacitor C1 connected in series, and the thyristor VT is connected in parallel with the damping circuit. The device includes a measurement and control system for applying an excitation source to the thyristor stage under test and a signal acquisition unit connected to the measurement and control system. The signal acquisition unit includes a voltage sensor and a measurement current for measuring the voltage signal at both ends of the damping loop during testing. The current sensor for the current signal of the damping loop is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com