Double-sided lithographic method

A double-sided photolithography and photolithography technology, which is applied in the direction of optics, optomechanical equipment, and photolithography on the pattern surface, can solve problems such as rotation deviation, inaccurate mask alignment, and alignment accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

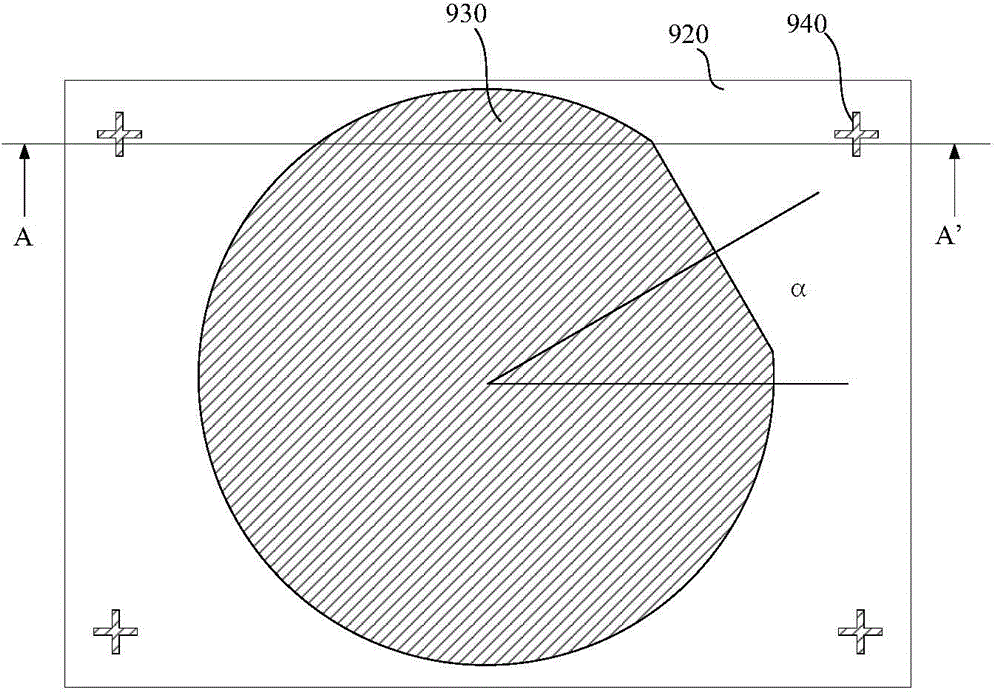

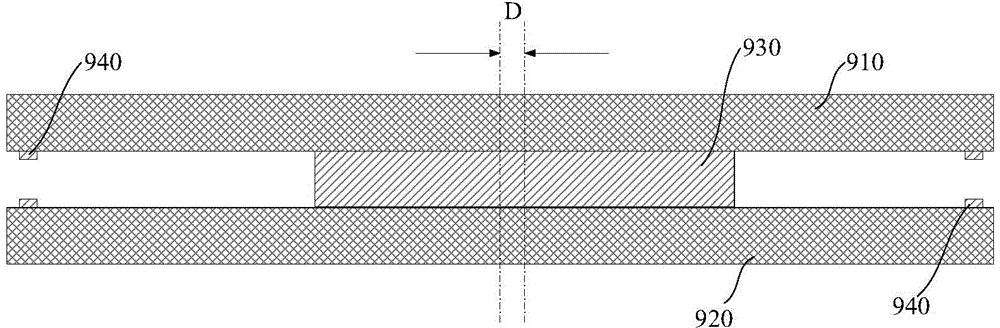

[0015] figure 1 is a plan view of the positional relationship between the reticle and the substrate in a traditional double-sided lithography process, figure 2 for figure 1 Sectional view along section line A-A'. Most double-sided lithography adopts proximity or contact exposure, so the ratio of the pattern on the photolithography plate to the pattern finally imaged on the substrate is 1:1. refer to figure 2 , the principle of traditional double-sided lithography is to sandwich the substrate 930 between the upper plate 910 and the lower plate 920, and then fix it with a fixture and send it to the exposure machine for exposure, so that the graphics can be directly formed on the substrate . Alignment marks 940 are used between the upper plate 910 and the lower plate 920. However, although the alignment marks 940 can be used between the upper plate 910 and the lower plate 920, the substrate 930 and the upper plate 910 or the lower plate 920 However, there is a lack of alig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com