Synchronous traction system and control method thereof

A technology of synchronous control and traction system, which is applied to electric controllers, controllers with specific characteristics, object supply, etc., and can solve problems such as PID controller parameter setting defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be described in detail below in conjunction with the examples, so as to fully understand and implement the implementation process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

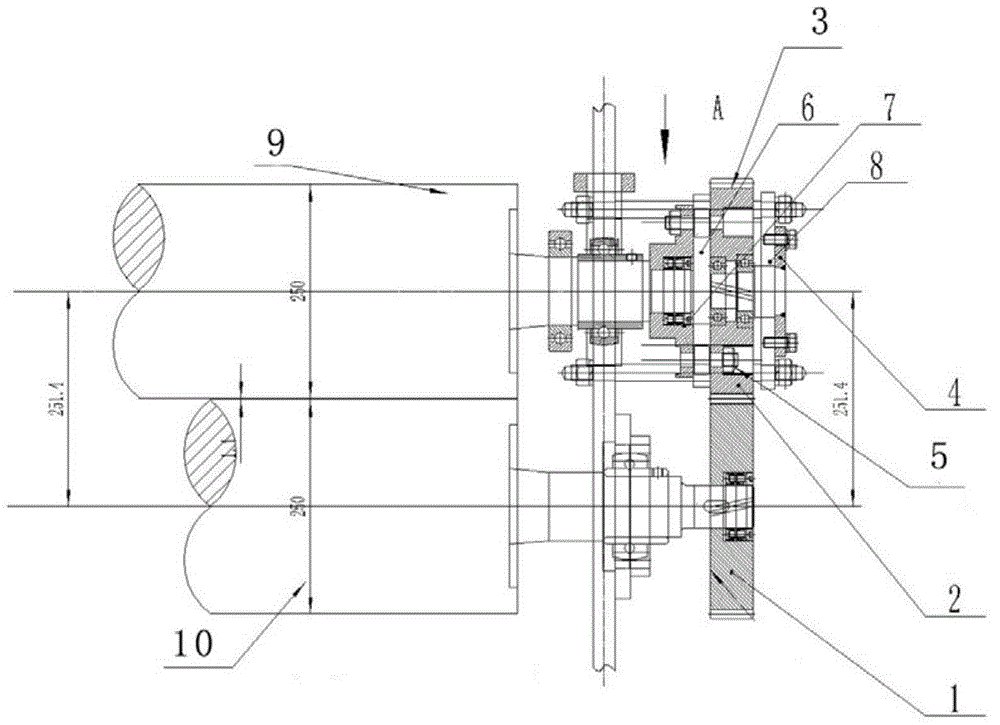

[0040]The invention relates to an up and down synchronous drive hollow plate tractor, including upper and lower rollers; upper and lower gears; intermediate gears, various bearings; The tractor of the active system of the present invention drives the sprocket through the reducer, the sprocket drives the lower roller, the lower roller drives the lower gear, and then the lower gear drives the upper gear to realize synchronous transmission up and down. The gear of the upper roller is added, mainly to improve the traction force of the tractor and the friction gap.

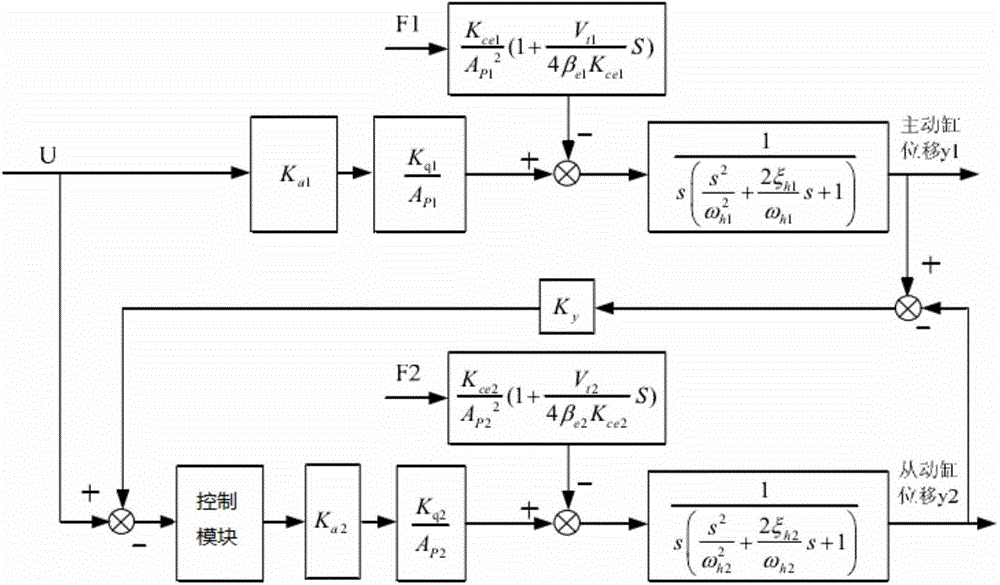

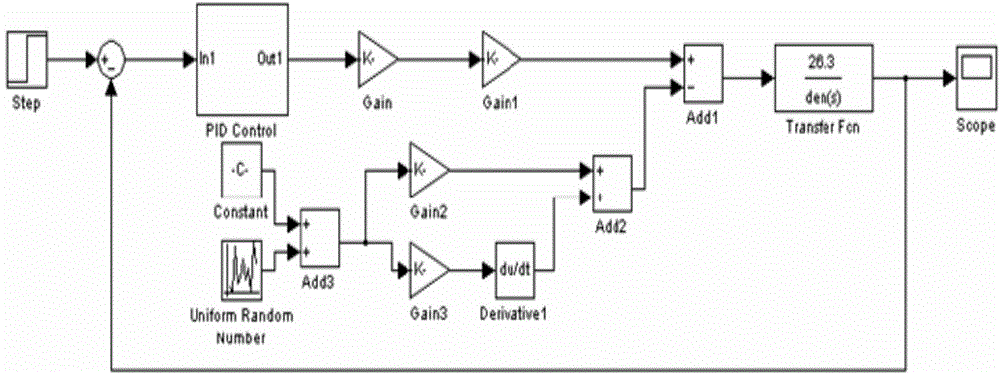

[0041] In addition, the present invention further has an optional lower roller power drive system and a hydraulic sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com