A Statistical Method of Utilization Rate Based on Operating State of Machining Equipment

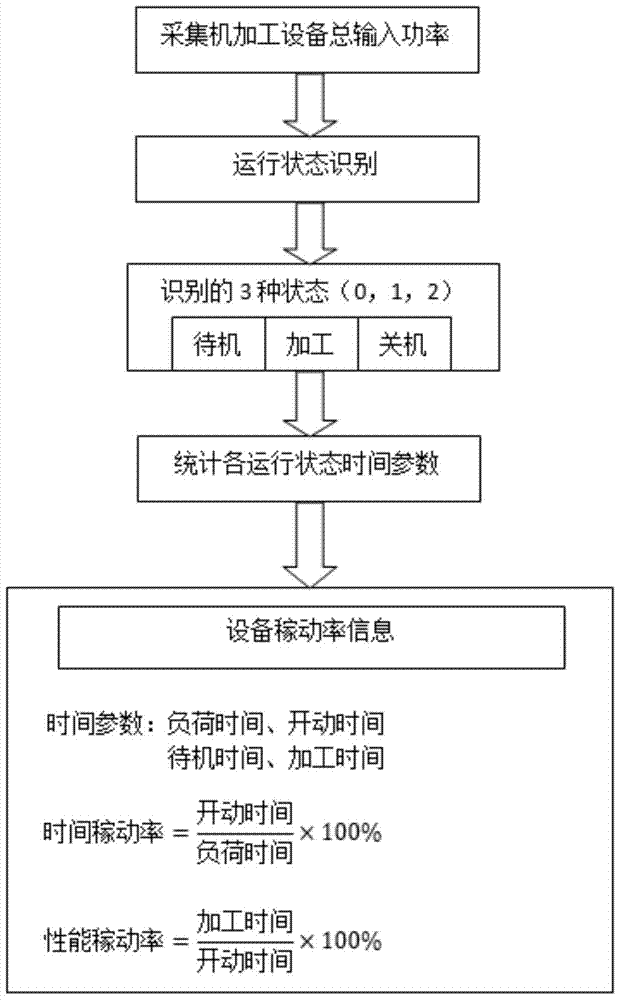

A technology for equipment operation and operation status, applied in the field of condition monitoring and energy consumption of machinery manufacturing industry, it can solve the problems of difficult realization of machining time parameters, low accuracy, and inability to meet requirements, so as to improve equipment utilization rate and utilization. The effect of high efficiency, strong resistance to voltage fluctuations, and high generalizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

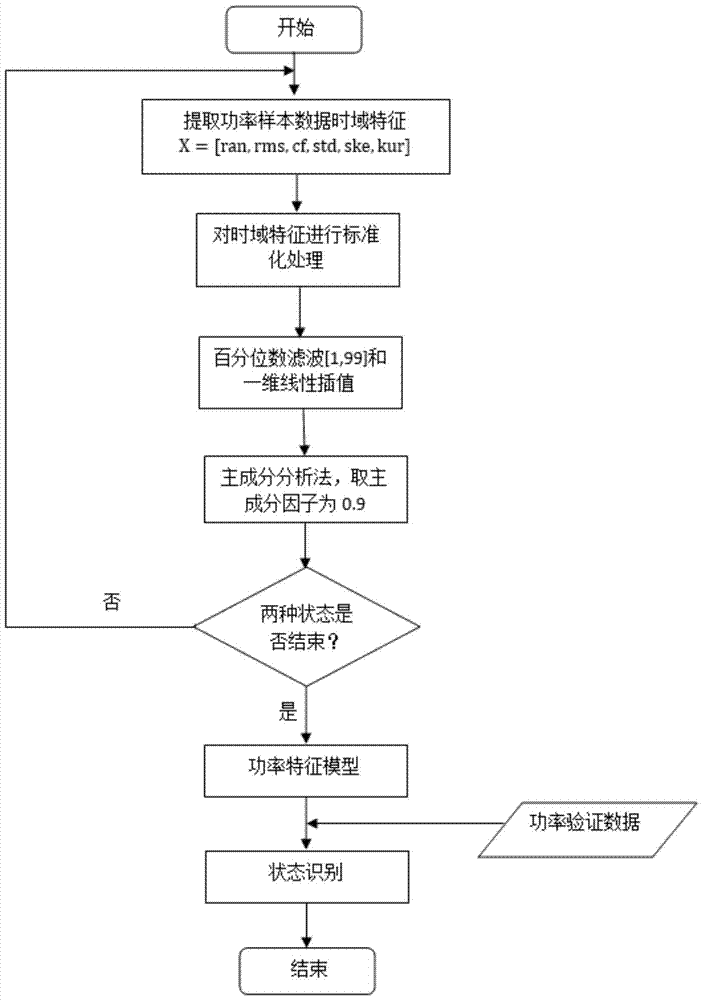

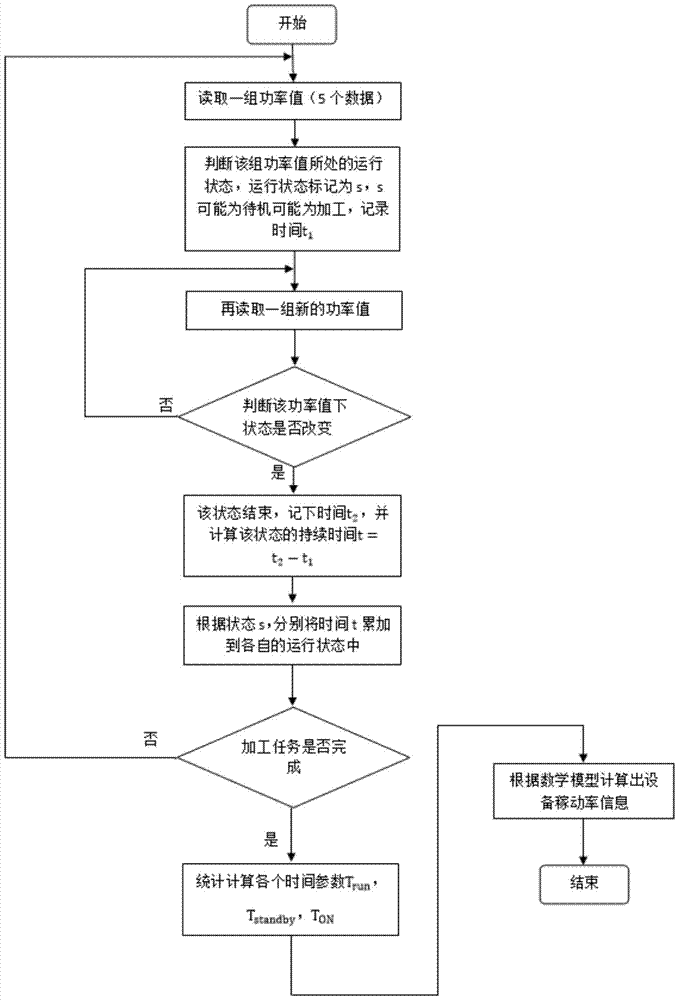

Method used

Image

Examples

Embodiment

[0053] The present invention uses a SmartCNC 500 numerical control machine tool in a certain workshop to carry out relevant experiments, and collects the input power data of the entire processing process (standby-processing-shutdown) in real time through a power sensor at the main power supply of the machine tool, and the sampling frequency is 5HZ. Collect two sets of data as needed: sample data and test data, ① collect sample data (30min), for the standby state, it is necessary to collect the input power of the standby state in different situations, such as the standby state before processing, and the standby state after processing state. For the processing state, the input power of multiple processing processes should be collected to ensure the integrity and comprehensiveness of the sample data; ② collect verification data (5min), and collect input power data of a complete processing process. ③Collect test data and directly collect input power data for the entire rated load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com