A kind of MOS tube and its manufacturing method

A manufacturing method and technology for MOS transistors, which are used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as low EAS and complex processes, and achieve the effect of improving EAS capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

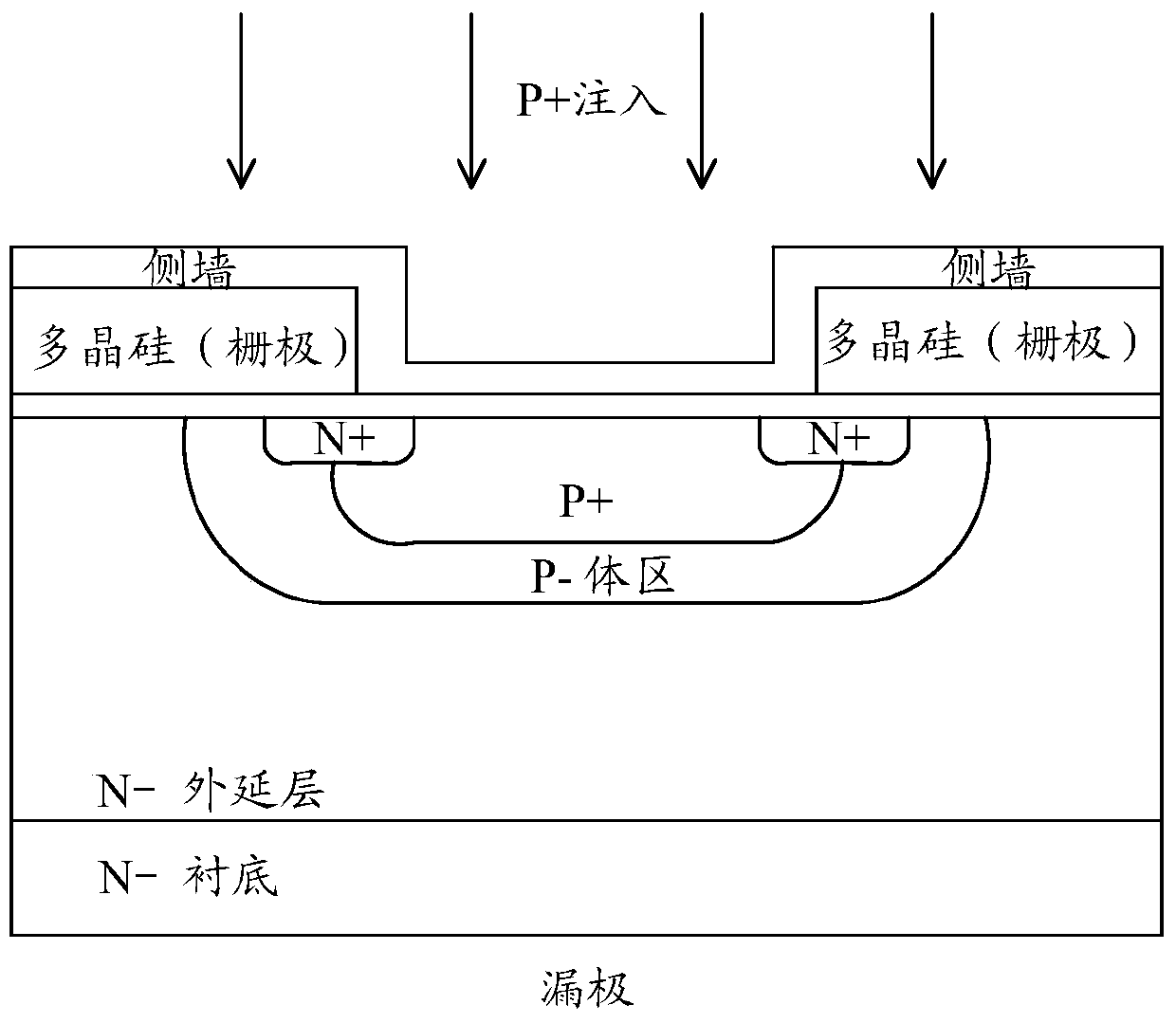

[0060] The present invention aims at the existing process of manufacturing MOS tubes. When injecting P+, Spacer needs to be precipitated, the process is complicated, and as the problem of low impact resistance of switches, a method for manufacturing MOS tubes is provided, which directly utilizes the method of self-alignment. P+ injection to get better EAS capability.

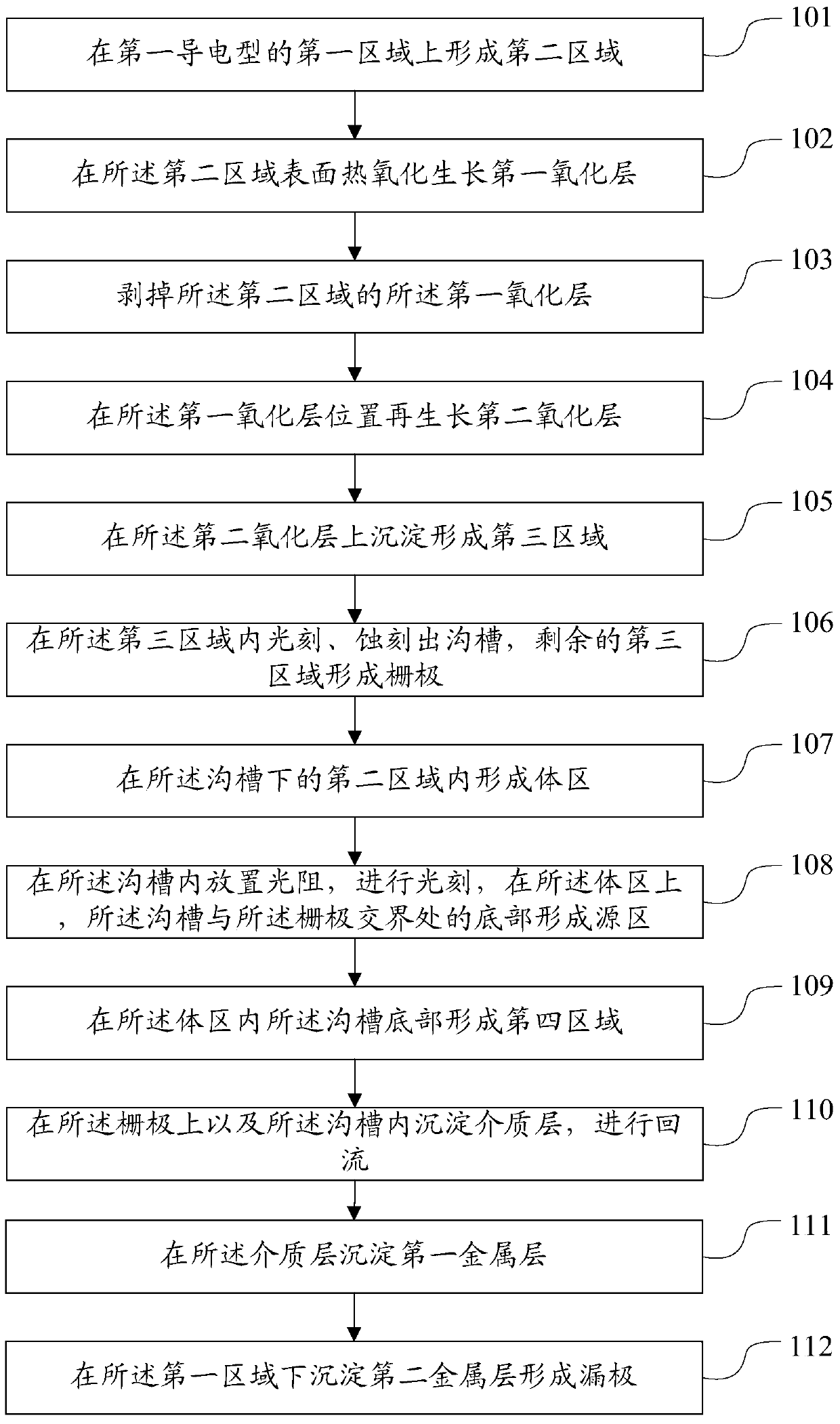

[0061] Such as figure 2 As shown, a method for manufacturing a MOS tube according to an embodiment of the present invention includes the following steps:

[0062] Step 101, forming a second region on the first region of the first conductivity type;

[0063] Step 102, growing a first oxide layer by thermal oxidation on the surface of the second region;

[0064] Step 103, peeling off the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com