High-voltage-resistant SGT device

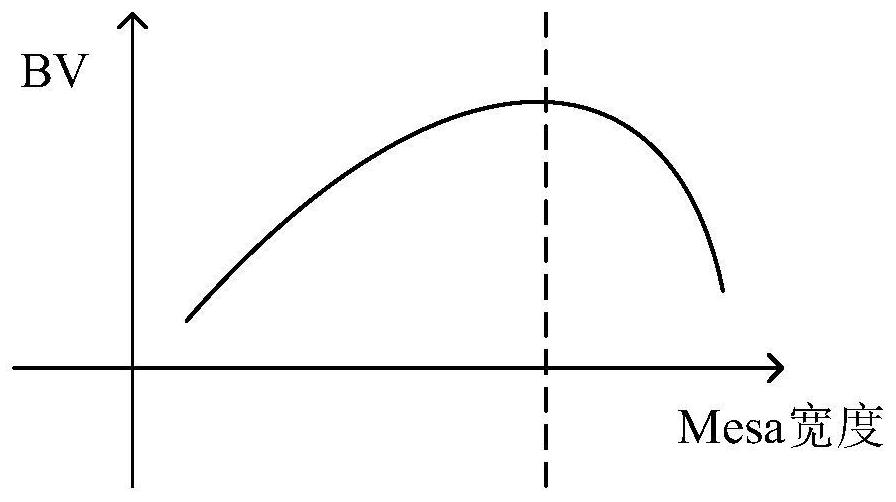

A technology of high withstand voltage and devices, which is applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., can solve the problem of lower breakdown voltage, lower breakdown withstand voltage BV at the corner of the cell trench 1 end, and reliability of SGT devices And EAS capacity reduction and other issues, to achieve the effect of improving the pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the specific drawings and embodiments.

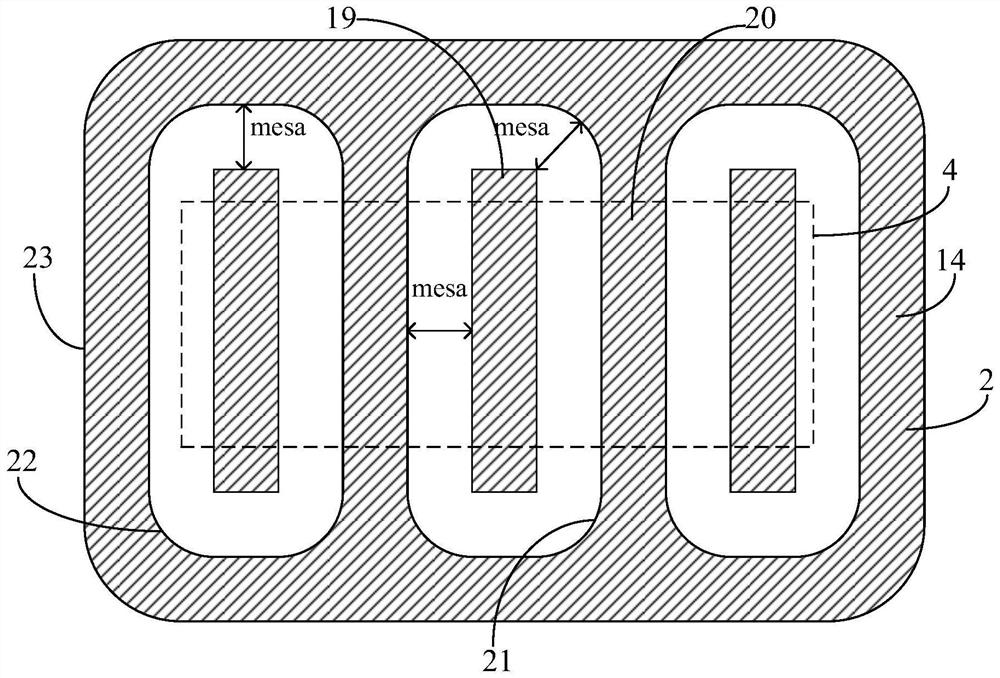

[0032] like image 3 Shown: In order to improve the withstand voltage capability, EAS capability and reliability of the SGT device, the present invention includes a semiconductor substrate, an active region 4 prepared in the central region of the semiconductor substrate, and a terminal for protecting the active region 4 area 2; the active area 4 includes a number of cells distributed in parallel, and the cells in the active area 4 adopt the SGT structure; the terminal area 2 at least includes a terminal inner ring 23 adjacent to and surrounding the active area 4, the The terminal inner ring 23 includes the terminal ring groove 14;

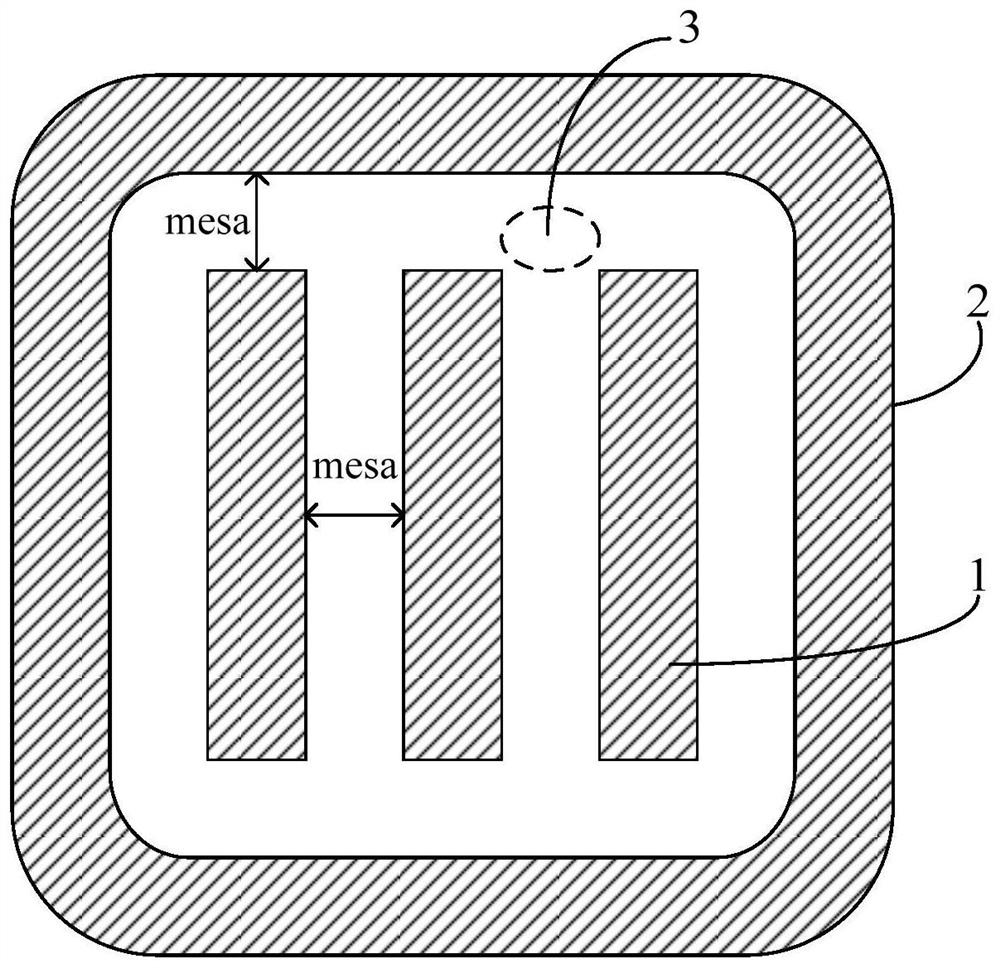

[0033] On the top plan view of the SGT device, the cells in the active region 4 are elongated, and along the direction perpendicular to the length of the cells, the active region 4 includes a plurality of first cell units 19 alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com