Super-junction device

A super junction device and gate structure technology, applied in the field of semiconductor integrated circuits, can solve the problems of reducing EAS capability, EAS burnout, reducing parasitic triode base current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

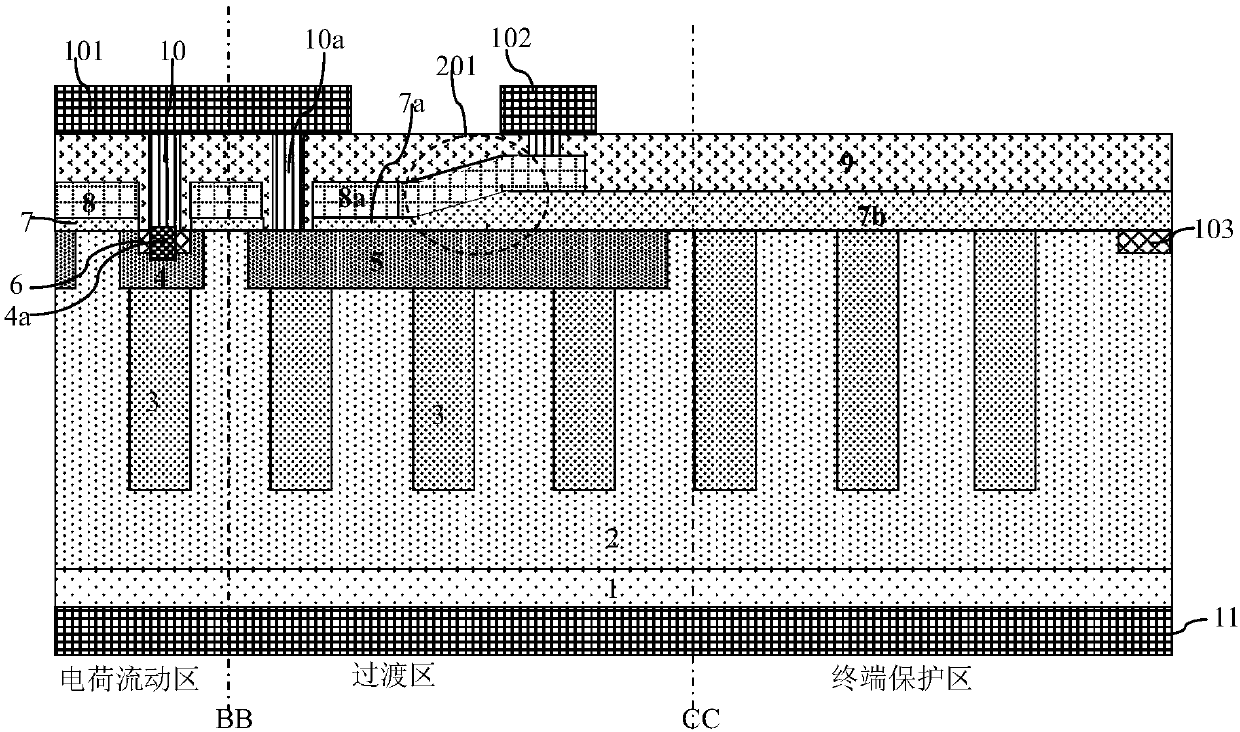

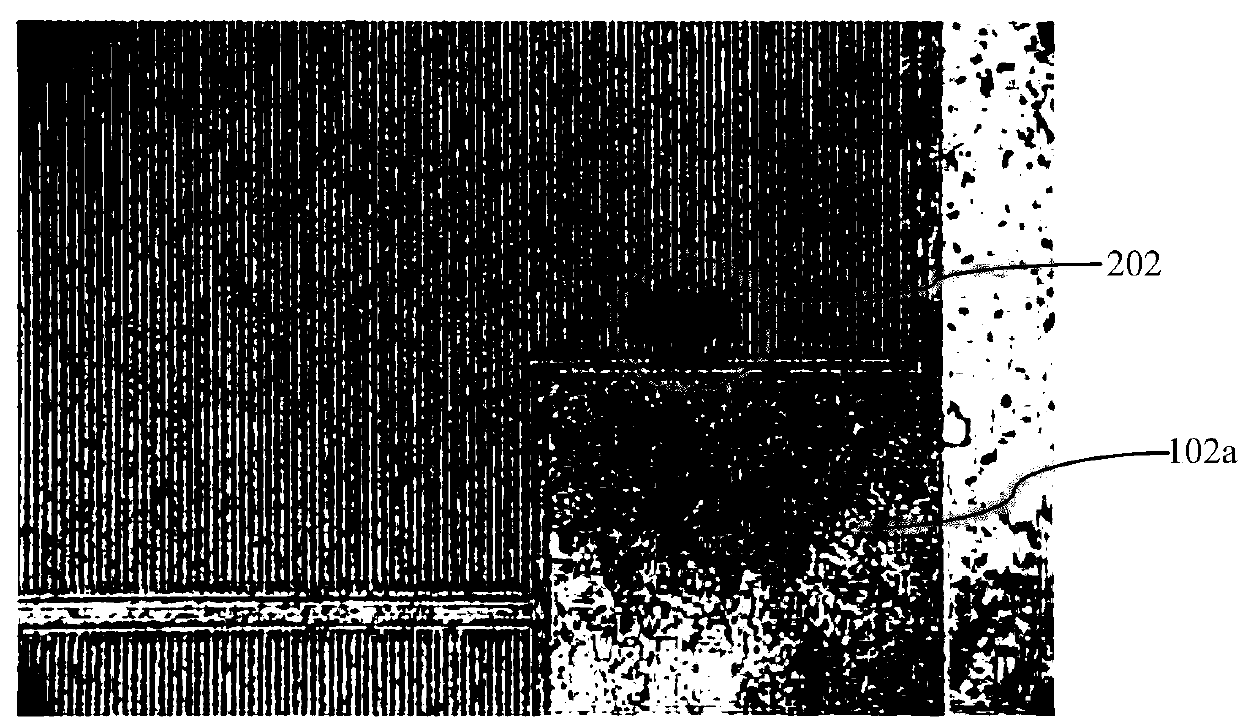

[0034] The technical solution of the embodiment of the present invention is obtained on the basis of analyzing the existing technical problems. Before introducing the technical solution of the embodiment of the present invention in detail, the structure of the existing super-junction device is described as follows, as follows figure 1 Shown is a schematic diagram of the layout structure of the existing super junction device; figure 2 yes figure 1 Schematic diagram of the cross-sectional structure of the device at the position of the AA line in the center; the middle region of the existing superjunction device is the charge flow region, the terminal protection region is formed on the peripheral side of the charge flow region, and the transition region is located between the terminal protection region and the charge flow region. between the flow areas, figure 2 In , the left side of the dotted line BB is the charge flow area, the area between the dotted line BB and CC is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com