Thermoelectric material and thermoelectric element including the same

A thermoelectric material and thermoelectric technology, applied in the direction of electrical components, thermoelectric devices, thermoelectric device node lead-out materials, etc., can solve the problems of being unusable, difficult to use in various ways, and not flexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

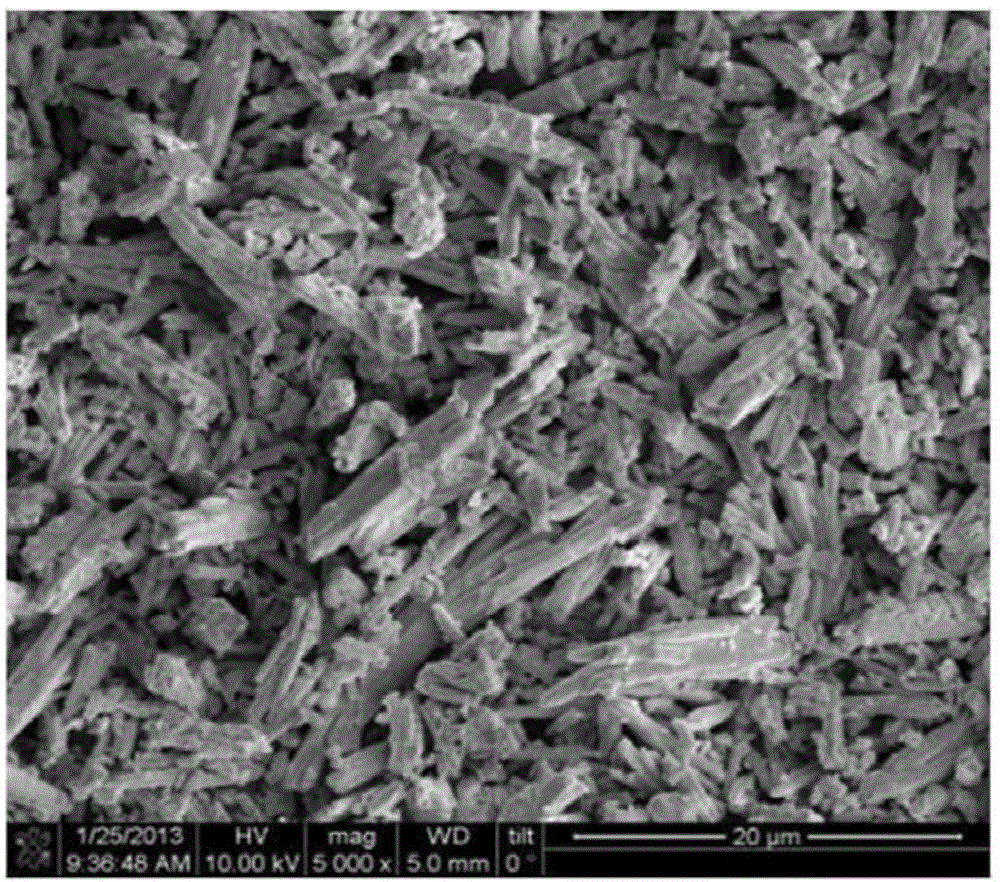

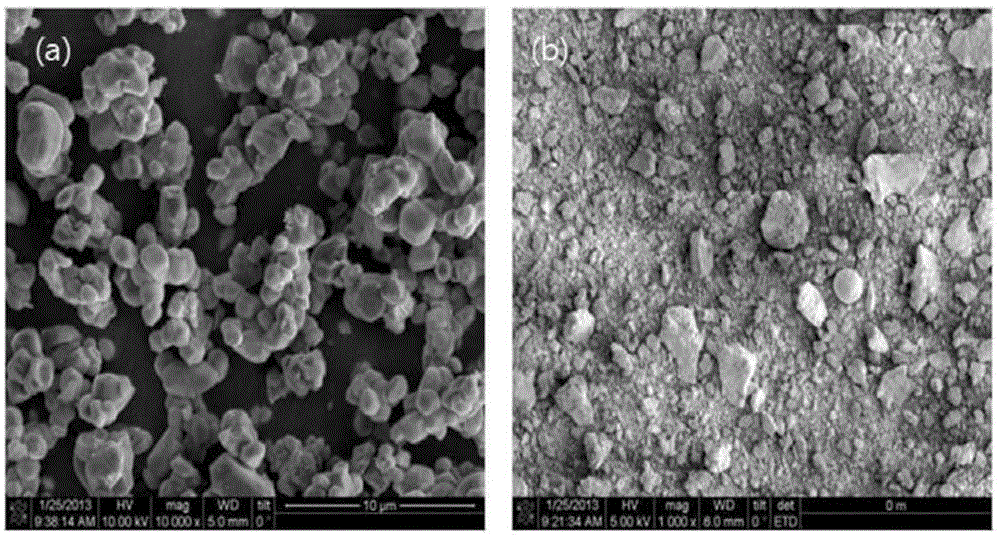

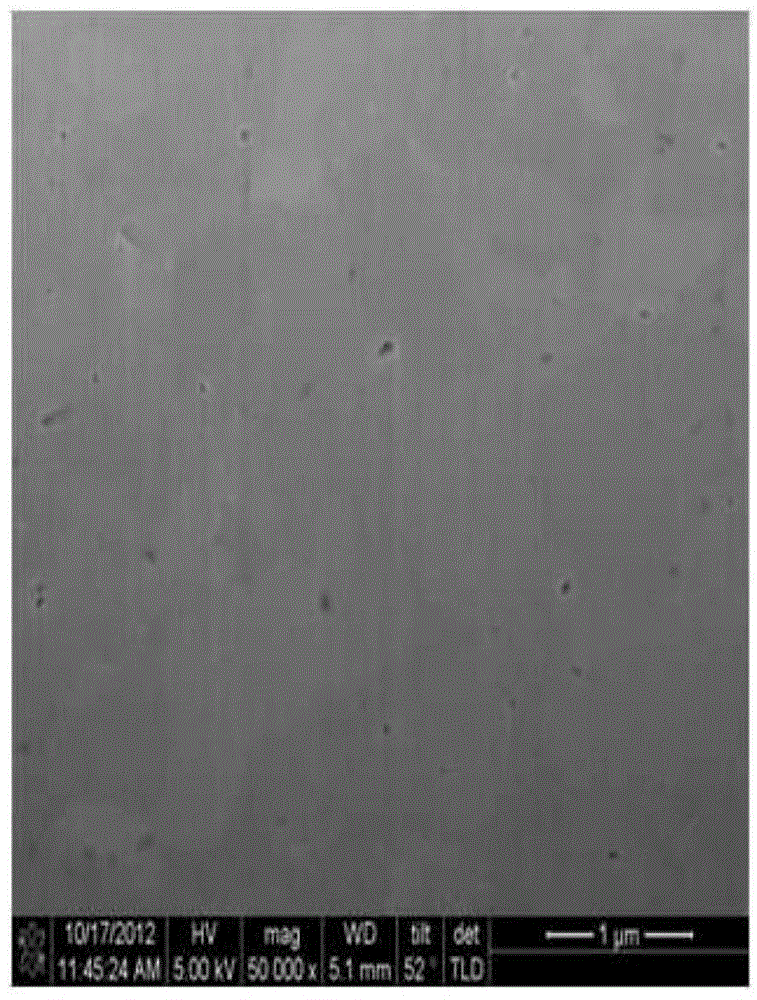

[0031] The thermoelectric material according to the first embodiment of the present invention may include: a thermoelectric powder including at least one element selected from Bi, Sb, Te, and Se; and a metal oxide powder having a cross section having a width and a thickness and has a length extending from the section. In particular, the metal oxide powder has a rod shape. A rod shape is defined as a structure with regular cross-section and length.

[0032] Specifically, the nanocrystalline thermoelectric material used for the thermoelectric element according to the first embodiment includes a metal oxide powder having a rod shape, and a thermoelectric powder; and the nanocrystalline thermoelectric material is realized in a bulk form. The thermoelectric material according to the first embodiment is configured such that thermoelectric powder is independently introduced into the interior of the bulk thermoelectric material, and particles of metal oxide powder having a rod shape ...

manufacture Embodiment 1

[0050] Production Example 1: Production of P-type Ingot

[0051] Each of Bi, Sb and Te samples were weighed to form Bi 0.5 Sb 1.5 Te 3 conditions, the sample was sealed in an inert atmosphere while contained in a quartz tube. Then, the sample contained in the quartz tube was placed in a furnace and melted at a temperature of 800° C. for 10 hours, and the melted sample was subjected to quenching to manufacture an ingot.

manufacture Embodiment 2

[0052] Production Example 2: Production of N-type Ingot 1

[0053] Each of Bi, Sb and Te samples were weighed to form Bi 2 Sb 2.70 Te 0.30 conditions, the sample was sealed in an inert atmosphere while contained in a quartz tube. Then, the sample contained in the quartz tube was placed in a furnace and melted at a temperature of 800° C. for 10 hours, and the melted sample was subjected to quenching to manufacture an ingot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com