Coated fabric for airbag

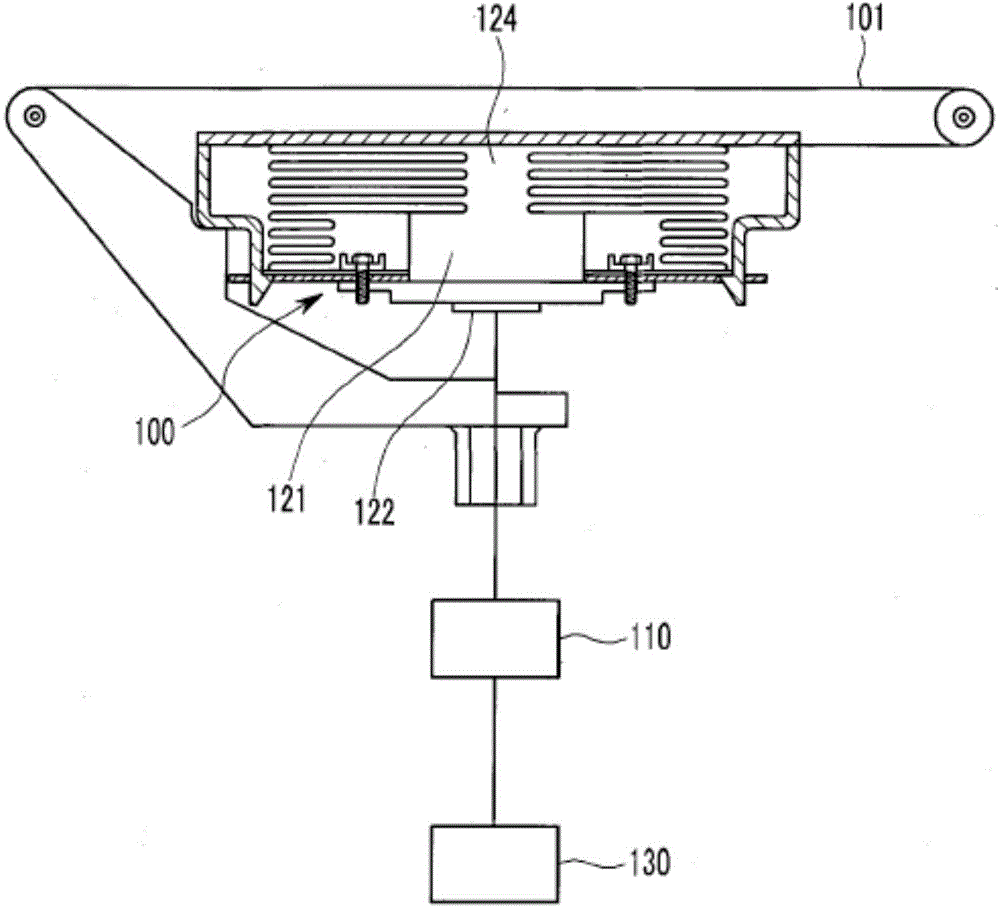

A technology of coated fabrics and airbags, applied in the direction of fabrics, fabric elongation, vehicle safety arrangements, etc., can solve the problems of difficult internal pressure, low elongation of liquid silicone rubber, etc., and achieve excellent mechanical properties and excellent internal pressure The effect of maintaining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0072] The gray cloth for the airbag is woven using 420 denier nylon 66 fibers woven by a jacquard machine. Here, the fabric density is adjusted to a warp density of 53 threads / inch and a weft density of 46 threads / inch.

[0073] The gray cloth undergoes a scouring process by passing through a chemical bath and a water bath, followed by a tentering process under a temperature condition of 160° C. to 180° C., thereby manufacturing an uncoated fabric for an airbag. Here, the fabric density of the woven fabric after scouring was 57 yarns / inch in warp and 49 yarns / inch in weft.

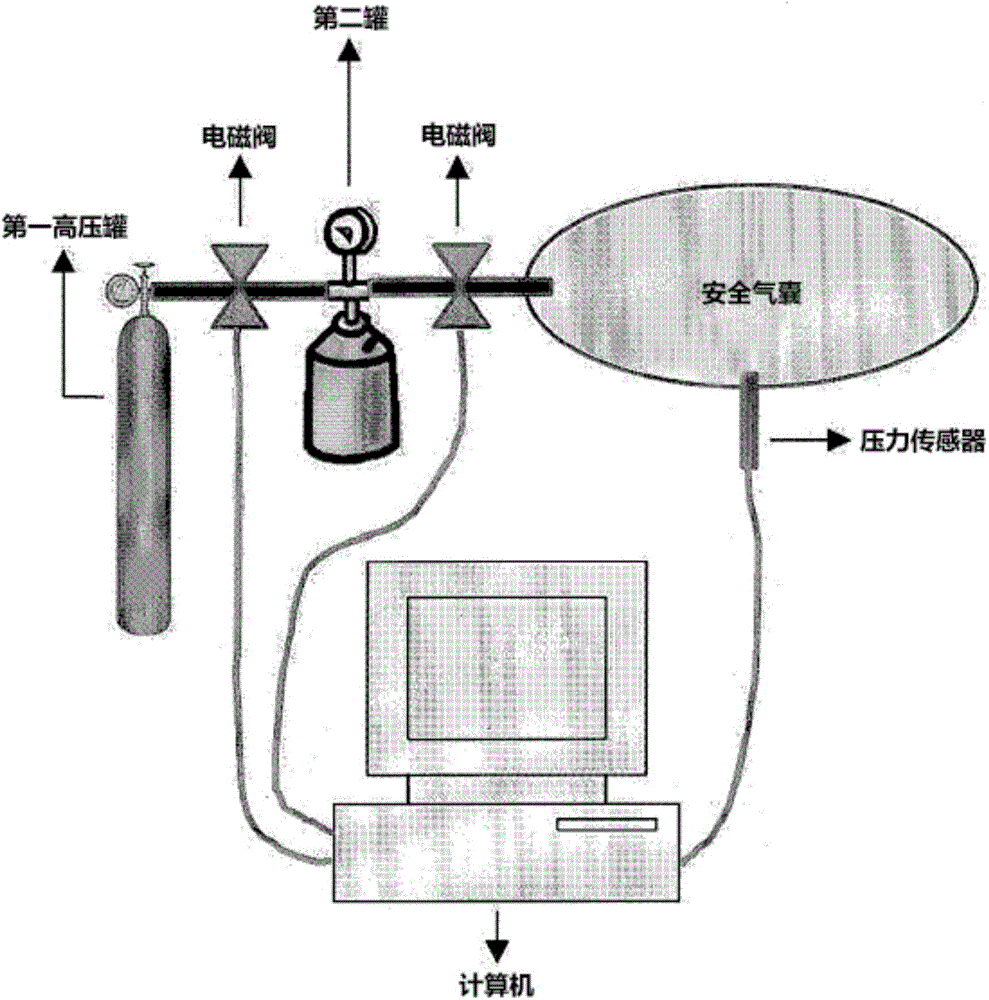

[0074] The uncoated fabric thus produced was coated with a silicon coating agent based on liquid silicone rubber (LSR) resin in an air-knife manner so that the silicone rubber coating amount was 55 g / m 2 up to 95g / m 2 , then dry. after drying,

[0075] The fabric was cured at a vulcanization temperature of 190° C. for 300 seconds to produce a silicon coated fabric for an airbag.

[0076] The elongati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com