Needleless connection piece

A needle connection and needle joint technology, applied in the field of needleless connectors, can solve the problems of slow elastic recovery speed, complex production, high requirements on materials and production processes, and achieve increased sealing performance, increased sealing effect, and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

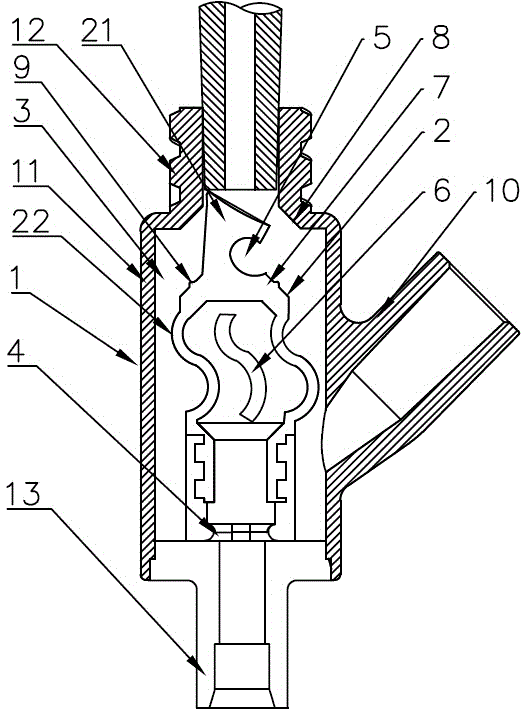

[0038] The invention provides a needleless connector, which has the characteristics of simple structure, low manufacturing cost, reliable insertion, precise closing, sufficient mechanical strength and smooth elastic recovery.

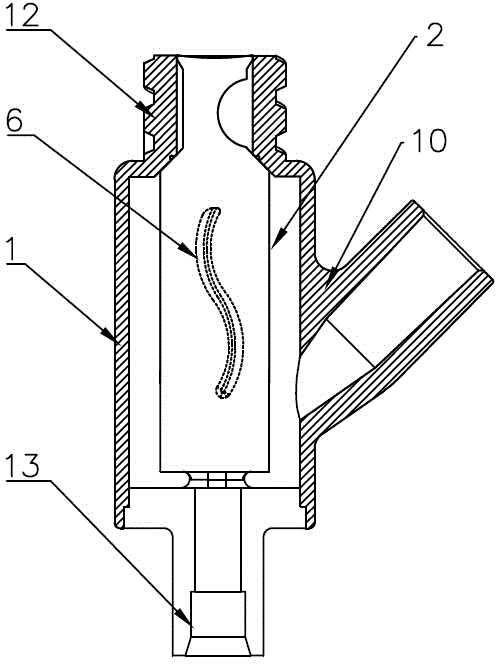

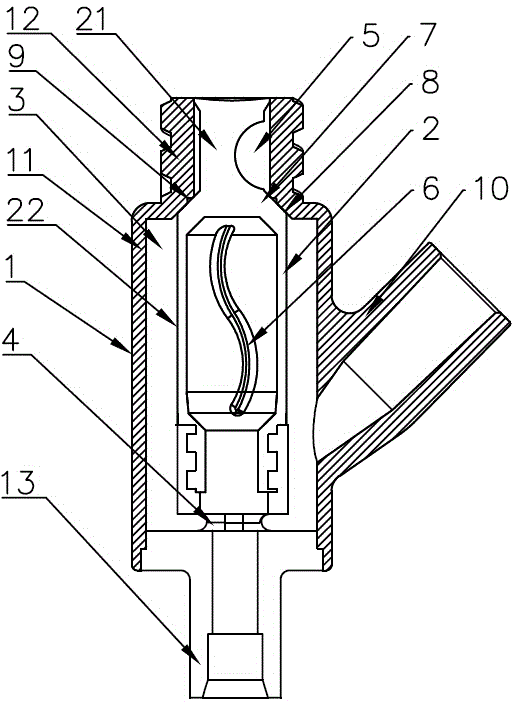

[0039] Such as Figure 1 to Figure 3 As shown, a needleless connector includes a needleless connector 1 and a rubber stopper 2. The rubber stopper is preferably a silicone rubber stopper, wherein the needleless connector 1 includes a cavity 11 with an inner cavity 3 and two sides of the cavity 11. The access port 12 and the output port 13 at the end, the access port 12 is connected to the external input device, the output port 13 is connected to the infusion catheter, and the cavity wall of the cavity 11 on the side of the output port 13 is provided with a wall extending to the inner cavity 3 and used to carry the rubber stopper The inner core seat 4 of 2; the rubber plug 2 includes a solid solid part 21 and a hollow hollow part 22, and the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com