Self-adaptation type floating ball demister and demisting method thereof

A self-adaptive, mist eliminator technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of difficult equipment maintenance, large equipment investment, low mist removal efficiency, etc., and achieve easy maintenance and replacement. Floating ball, less investment, convenient and quick maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

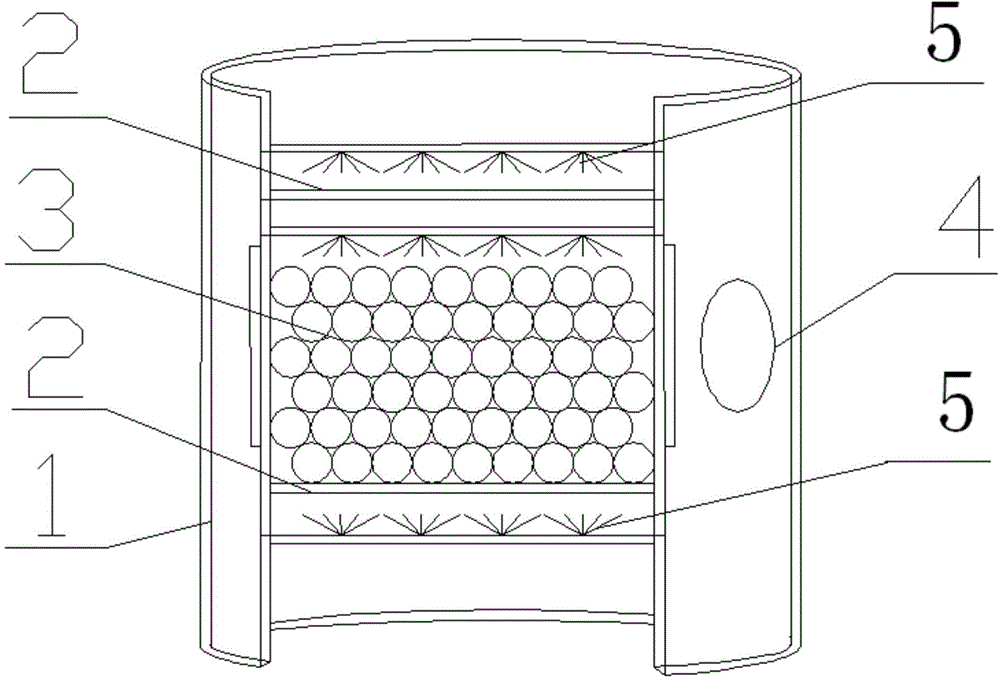

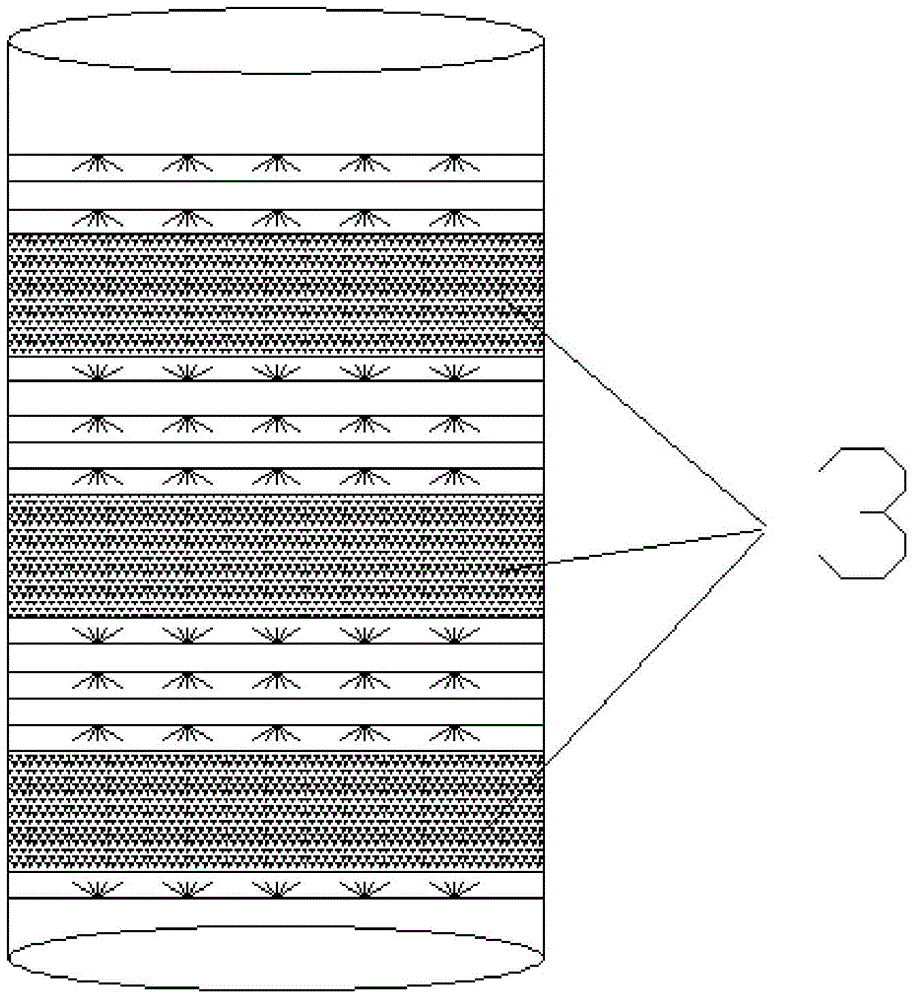

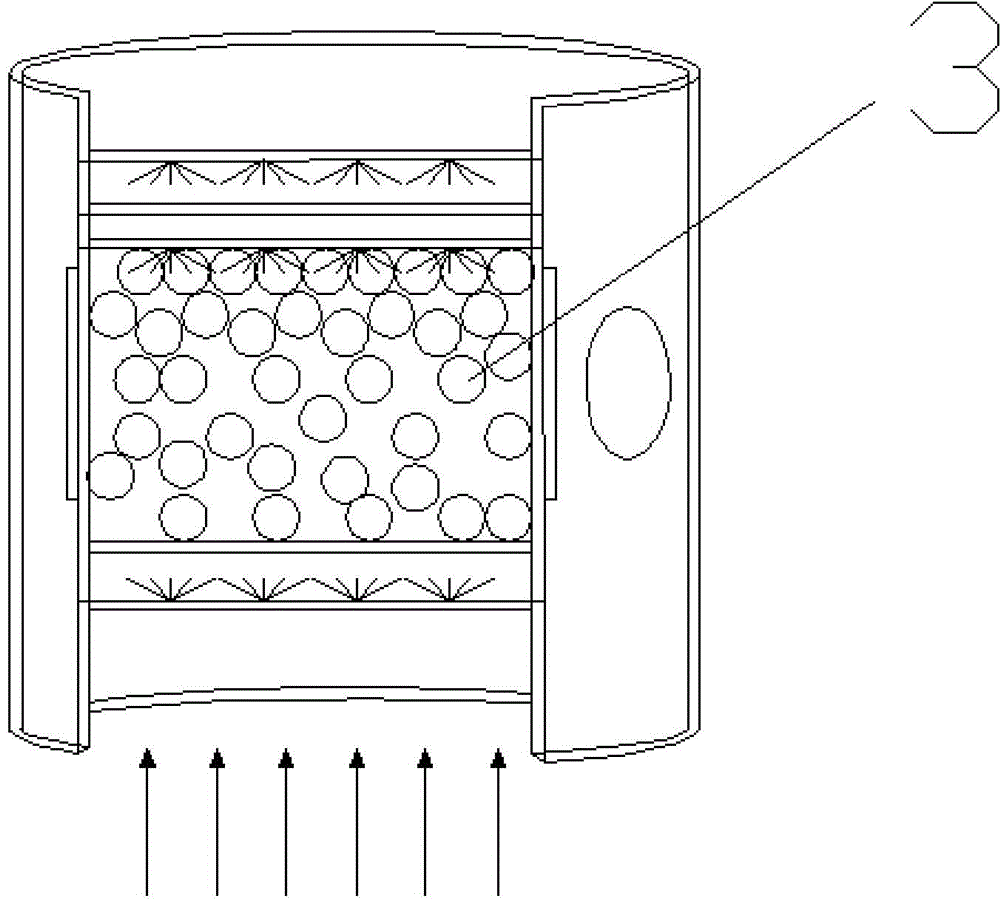

[0026] like Figures 1 to 3 shown. The self-adaptive floating ball demister of the present invention comprises a demister housing 1, a multi-layer floating ball demister unit 3 is arranged in the demister housing 1, and each floating ball demister unit 3 is separated by a sieve plate 2 open; each floating ball defogging unit 3 is formed by stacking a plurality of floating balls.

[0027] The floating ball is a hollow floating ball made of corrosion-resistant polymer material with a diameter of about 50mm-80mm.

[0028] The sieve plate 2 is a baffle plate, a wire mesh or a perforated plate.

[0029] A spray layer 5 for cleaning the floating ball and the sieve plate 2 is arranged above and / or below the floating ball demisting unit 3 . The spray layer 5 is connected with high-pressure water, and the floating ball and the sieve plate 2 are washed regularly.

[0030] A movable door 4 (transparent material) is arranged on the side wall of the demister housing 1 corresponding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com