Preparation method and construction method of PVC (polyvinyl chloride) soft plastic water drip

A drip line and plastic technology, applied in the direction of condensed water discharge, construction, building structure, etc., can solve the problems of not meeting the requirements and expectations, failing to achieve refinement, increasing the workload of operators, etc., to achieve good appearance effect, Solve the effect of difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Example: Building 17# of the first phase of the renovation project of the state-run Donghua Machinery Factory in Datong City is a high-rise residential building with a shear wall structure, with a total construction area of 18613.25 square meters and a total height of 54.04 meters. The basement is 1 floor. The project design basement is the air defense layer. The lower part of the stair treads, the window, the awning, and the lower part of the air-conditioning board all involve the construction of the drip line.

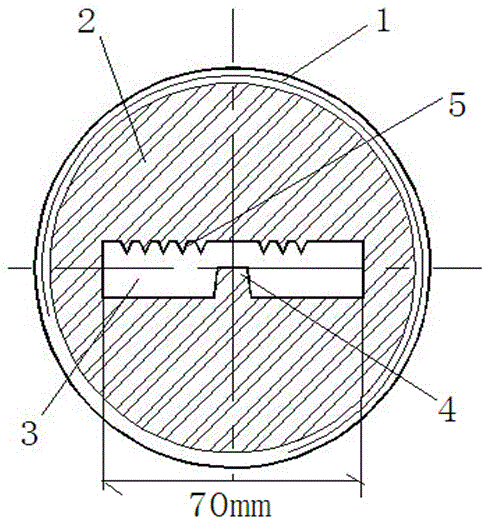

[0030] The PVC drip line forming mold is improved on the basis of making the PVC pipe heat mixer, that is, the machine head of the PVC pipe heat mixer is replaced with figure 1 Extruder die shown.

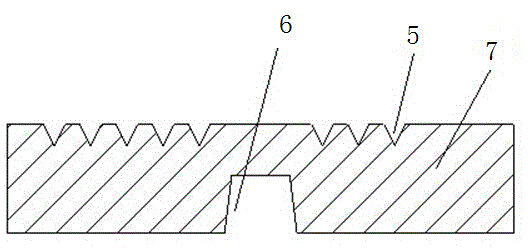

[0031] figure 1 As shown, the width of the mold groove 3 on the PVC soft plastic drip line extrusion head mold installed on the roof plate is 70mm, the thickness is 15mm, and there is a rib 4 in the middle, the height of the rib is 8mm, and the width is 10mm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com