Inorganic modified asphalt and preparation method thereof

An inorganic modification and asphalt technology, applied in building components, building insulation materials, buildings, etc., can solve problems such as the problem of rutting that cannot be fundamentally solved, and achieve the effect of alleviating high-temperature rutting diseases, hindering heat loss, and reducing total heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

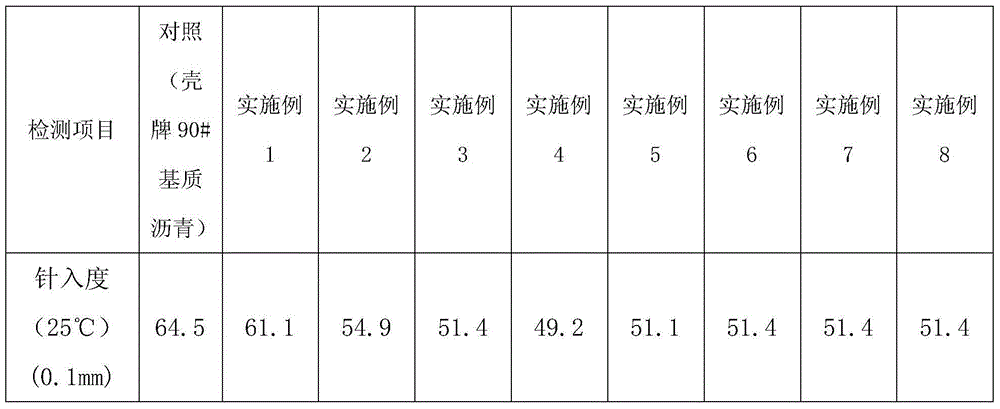

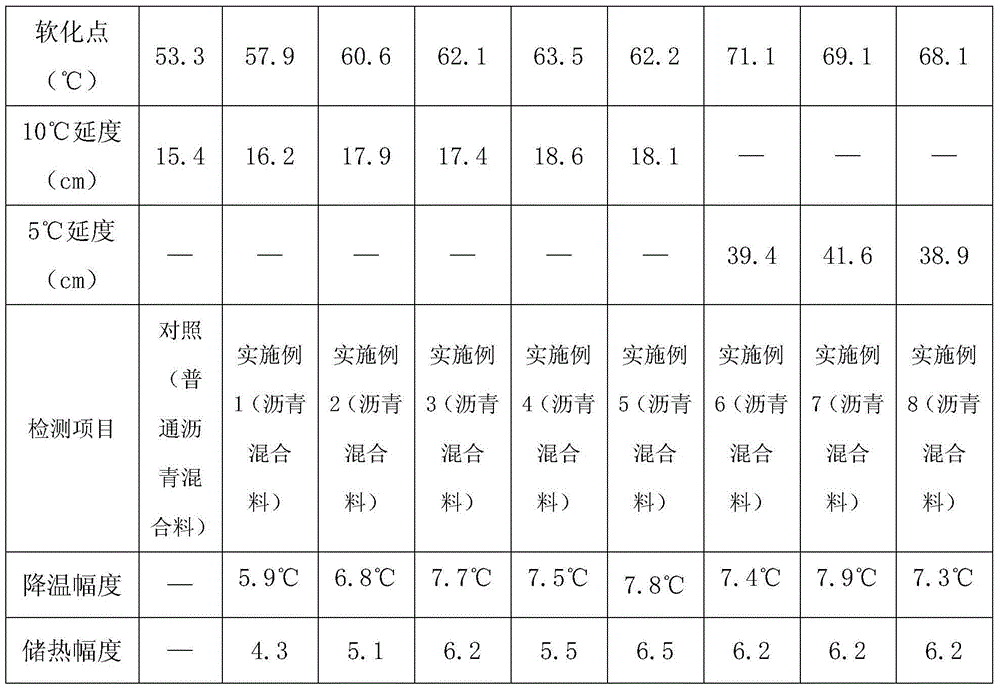

Examples

Embodiment 1

[0021] An inorganic modified asphalt, made by mixing the following raw materials in parts by weight: 100 parts of basic asphalt, 5.5 parts of boronite, 3.5 parts of albite, 4 parts of silica gel powder, 1 part of microcrystalline cellulose, and 0.5 part of triethanolamine , 2 parts of auxiliary agent; The auxiliary agent is Iranian rubber oil extraction oil. The base asphalt is Shell 90# base asphalt; the boron is manganese boronite, and the fineness is 100 mesh; the albite is albite powder, and the fineness is 100 mesh; the silica gel powder is column The layer chromatography silica gel powder has a fineness of 100-400 meshes; the microcrystalline cellulose is microcrystalline cellulose with a cellulose content ≥ 80%; the purity of the triethanolamine must be above 80%.

[0022] The preparation method of the inorganic modified asphalt in this example is as follows: heat the base asphalt to 120°C, then add triethanolamine and additives to the heated base asphalt, stir well and...

Embodiment 2

[0024] The inorganic modified asphalt of this embodiment is prepared by mixing the following raw materials in parts by weight: 100 parts of basic asphalt, 10.5 parts of boborite, 6.5 parts of albite, 6 parts of silica gel powder, 1.5 parts of microcrystalline cellulose, triethanolamine 0.5 parts, 3 parts of auxiliary agent; said auxiliary agent is furfural extract oil. The base pitch is Shell 90# matrix pitch; the boron is manganese boron, and the fineness is 300 mesh; the albite is albite powder, and the fineness is 100 mesh; the silica gel powder is column Layer chromatography silica gel powder, the fineness is 100-400 mesh;

[0025] The preparation method of the inorganic modified asphalt in this example is as follows: heat the base asphalt to 140°C, then add triethanolamine and additives to the heated base asphalt, and then add boborite, albite, and silica gel to the heated base asphalt. powder and microcrystalline cellulose; using a high-speed shearing machine to shear t...

Embodiment 3

[0027] The inorganic modified asphalt of this embodiment is prepared by mixing the following raw materials in parts by weight: 100 parts of basic asphalt, 15.5 parts of boronite, 10.5 parts of albite, 8 parts of silica gel powder, 2 parts of microcrystalline cellulose, triethanolamine 1 part, 4 parts of auxiliary agent; The auxiliary agent is Iranian rubber oil extraction oil. The base asphalt is Shell 90# base asphalt; the boron is manganese boronite with a fineness of 500 mesh; the albite is albite powder with a fineness of 300 mesh; the silica gel powder is column Layer chromatography silica gel powder, the fineness is 100-400 mesh;

[0028] The preparation method of the inorganic modified asphalt in this example is as follows: heat the base asphalt to 160°C, then add triethanolamine and additives to the heated base asphalt, stir well and then add boronite, albite, silica gel powder and microcrystalline cellulose; using a high-speed shearing machine to shear the obtained m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com