Near-UV excited single matrix white phosphor and preparation method thereof

A technology of near-ultraviolet light and fluorescent powder, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of device lumen efficiency and color restoration, and achieve stable color development, good color restoration, and high lumen efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] According to the value range of phosphor powder x and y, take x=0.15, y=0.05, then the chemical composition of phosphor powder is Ca 2 Y 2.4 Sb 3 o 14 :0.15Bi 3+ ,0.05Eu 3+ . According to this chemical composition, the proportioning ratio of each raw material is calculated as shown in Table 1.

[0039] Table 1: Ca 2 Y 2.4 Sb 3 o 14 :0.15Bi 3+ ,0.05Eu 3+ Raw material ratio of phosphor powder

[0040] raw material

quality

CaCO 3

2.022 grams

Y 2 o 3

2.709 grams

Sb 2 o 3

4.417 grams

Bi 2 o 3

1.048 grams

Eu 2 o 3

0.264 grams

h 3 BO 3

0.3 grams

[0041] Accurately weigh the above raw materials, grind them carefully in an agate mortar, and put them into a small alumina crucible. Calcined at 1350° C. for 8 hours, cooled naturally to room temperature, taken out, and crushed and ground the resultant to obtain the white phosphor material in Example 1.

[0042]...

Embodiment 2

[0046] According to the value range of phosphor powder x and y, x=0.15, y=0.02, then the chemical composition of phosphor powder is Ca 2 Y 2.49 Sb 3 o 14 :0.15Bi 3+ ,0.02Eu 3+ . According to this chemical composition, calculate the proportioning ratio of each raw material as shown in Table 2.

[0047] Table 2: Ca 2 Y 2.4 Sb 3 o 14 :0.15Bi 3+ ,0.02Eu 3+ Raw material ratio of phosphor powder

[0048] raw material

quality

CaCO 3

2.022 grams

Y 2 o 3

2.811 grams

Sb 2 o 3

4.417 grams

Bi 2 o 3

1.048 grams

Eu 2 o 3

0.105 grams

h 3 BO 3

0.3 grams

[0049] Accurately weigh the above raw materials, grind them carefully in an agate mortar, and put them into a small alumina crucible. Calcined at 1400°C for 6 hours, cooled naturally to room temperature, taken out, crushed and ground the resultant to obtain the example material.

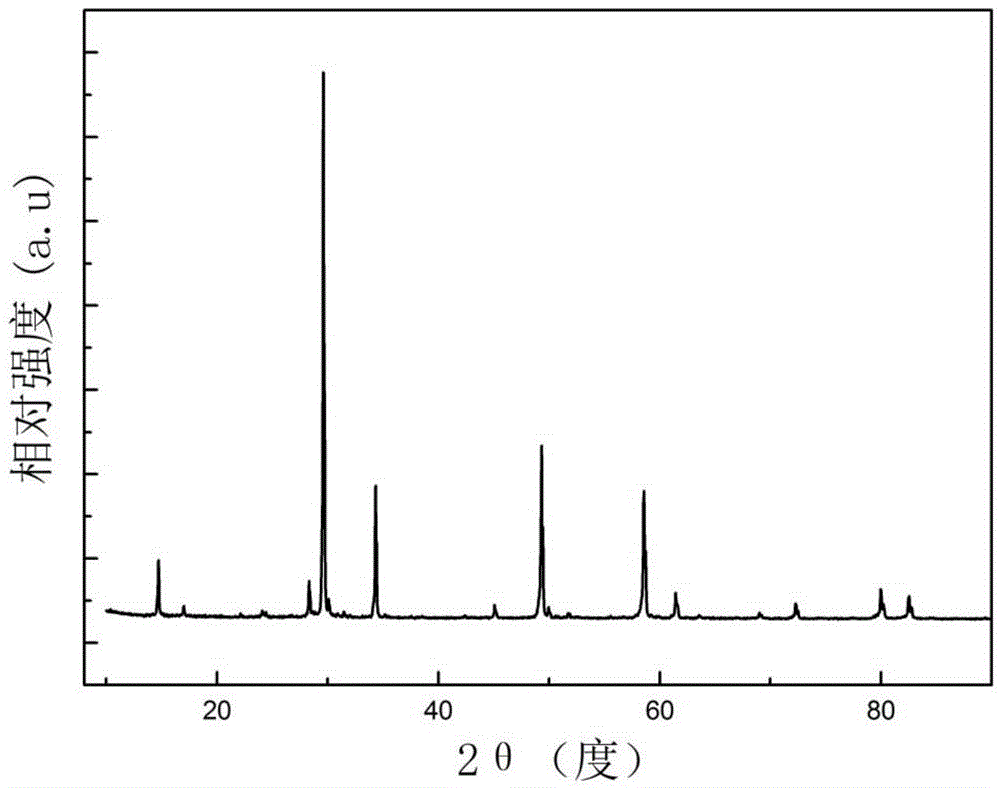

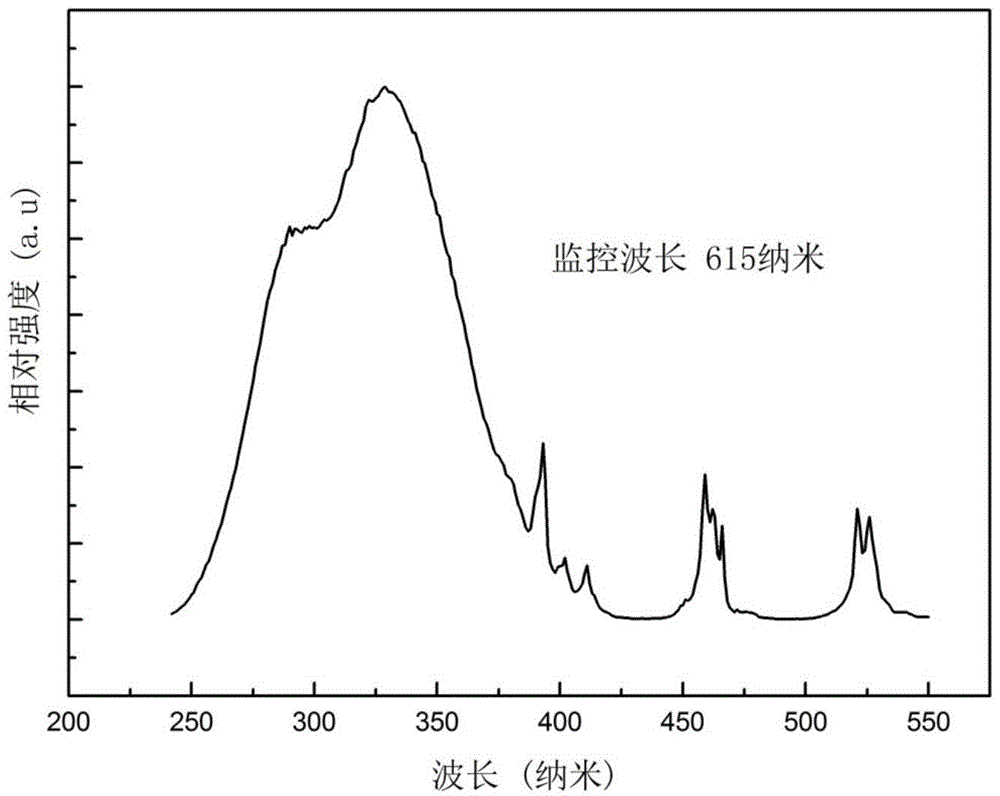

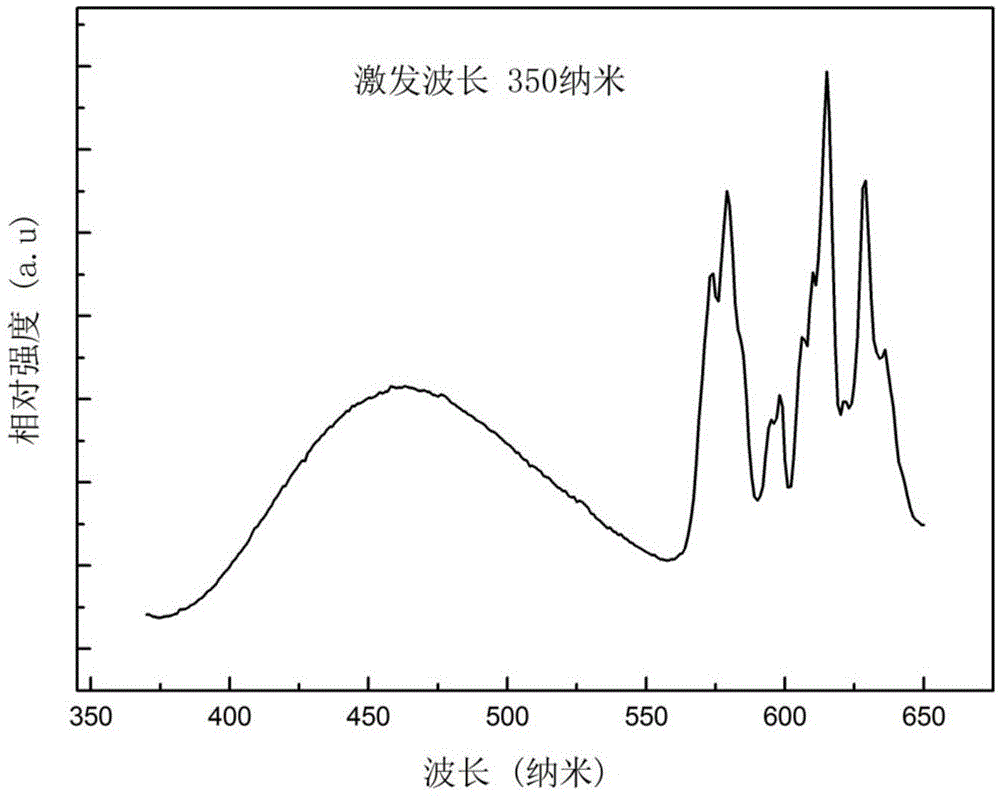

[0050] Such as Figure 4 Shown, the X-r...

Embodiment 3

[0054] According to the value range of phosphor powder x and y, take x=0.15, y=0.03, then the chemical composition of phosphor powder is Ca 2 Y 2.52 Sb 3 o 14 :0.15Bi 3+ ,0.03Eu 3+ . According to this chemical composition, the proportioning ratio of each raw material is calculated as shown in Table 3.

[0055] Table 3: Ca 2 Y 2.52 Sb 3 o 14 :0.15Bi 3+ ,0.03Eu 3+ Raw material ratio of phosphor powder

[0056] raw material

weight

CaCO 3

2.022 grams

Y 2 o 3

2.777 grams

Sb 2 o 3

4.417 grams

Bi 2 o 3

1.048 grams

Eu 2 o 3

0.158 grams

h 3 BO 3

0.3 grams

[0057] Accurately weigh the above raw materials, grind them carefully in an agate mortar, and put them into a small alumina crucible. Calcined at 1500°C for 4 hours, cooled naturally to room temperature, taken out, and the resultant was crushed and ground to obtain the example material.

[0058] Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com