A method for extracting bergamot essential oil by continuous phase change at low temperature and bergamot essential oil

A low-temperature continuous phase change, bergamot technology, applied in the direction of essential oils/spice, fat production, etc., can solve the problems of no reference regularity, low temperature continuous phase change extraction effect, etc., to achieve continuity suitable for large-scale industrialization Production, reducing the loss of low-boiling components, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

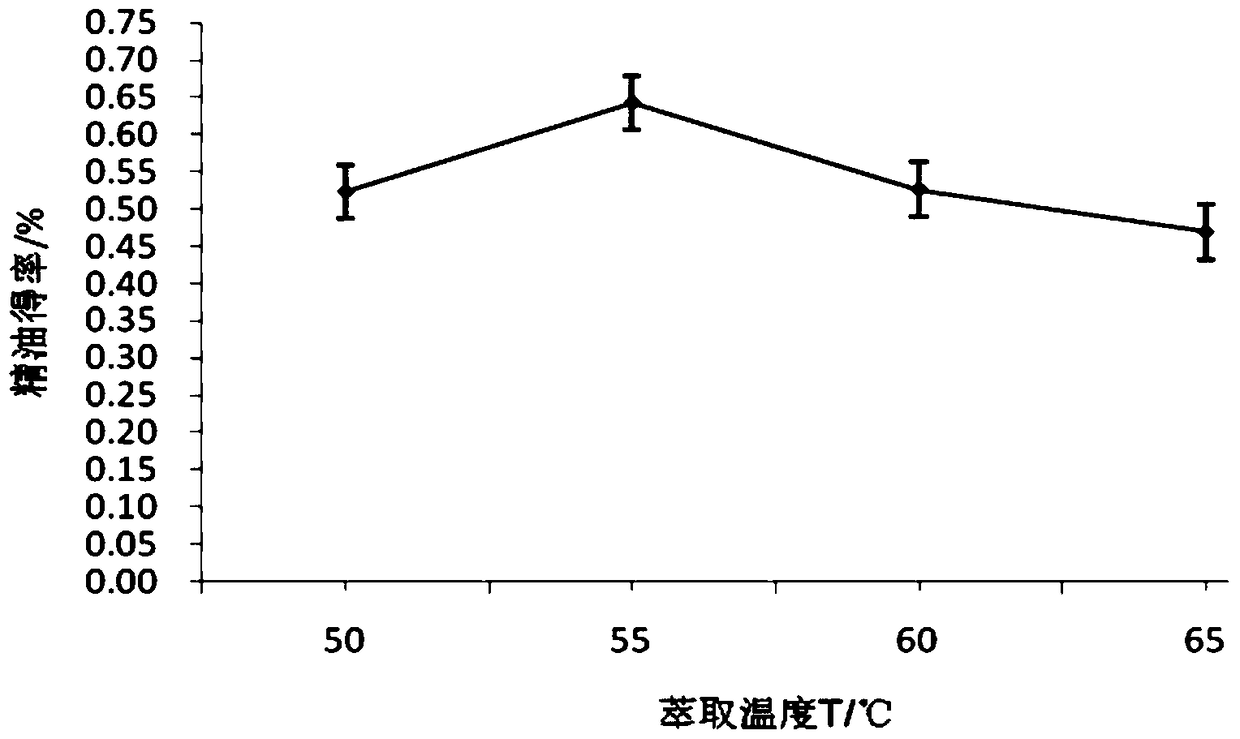

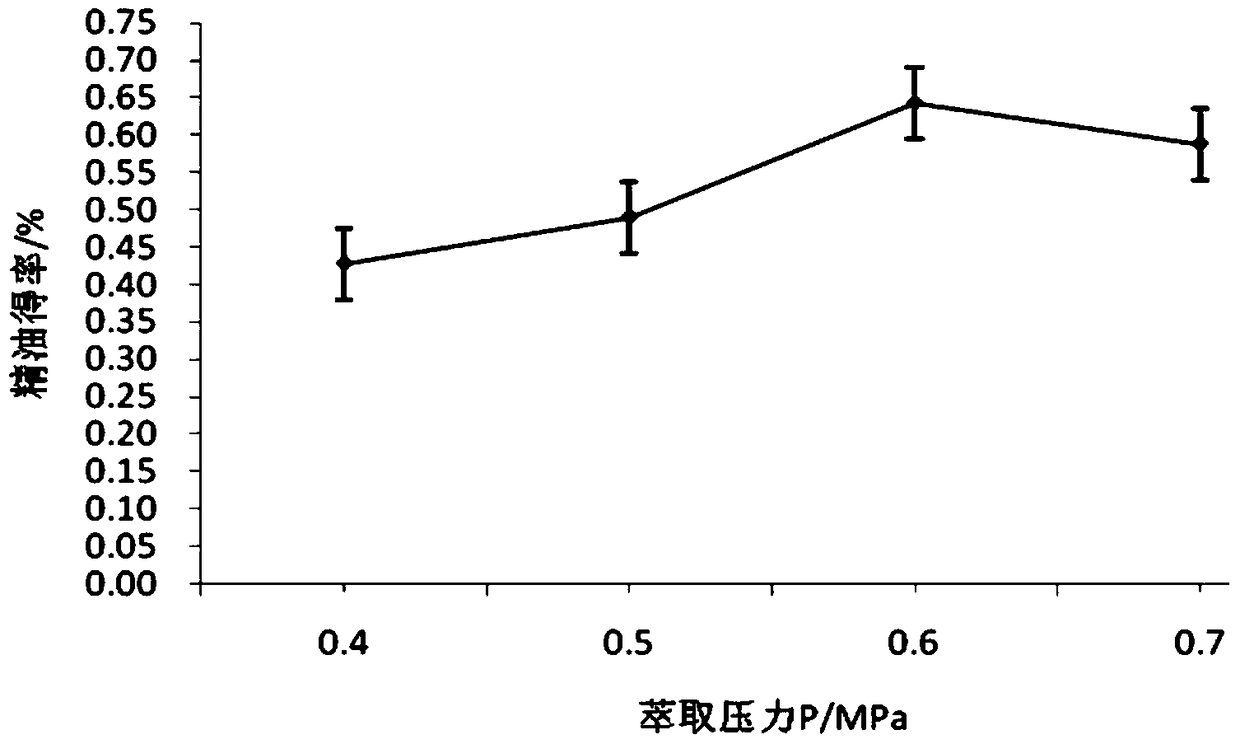

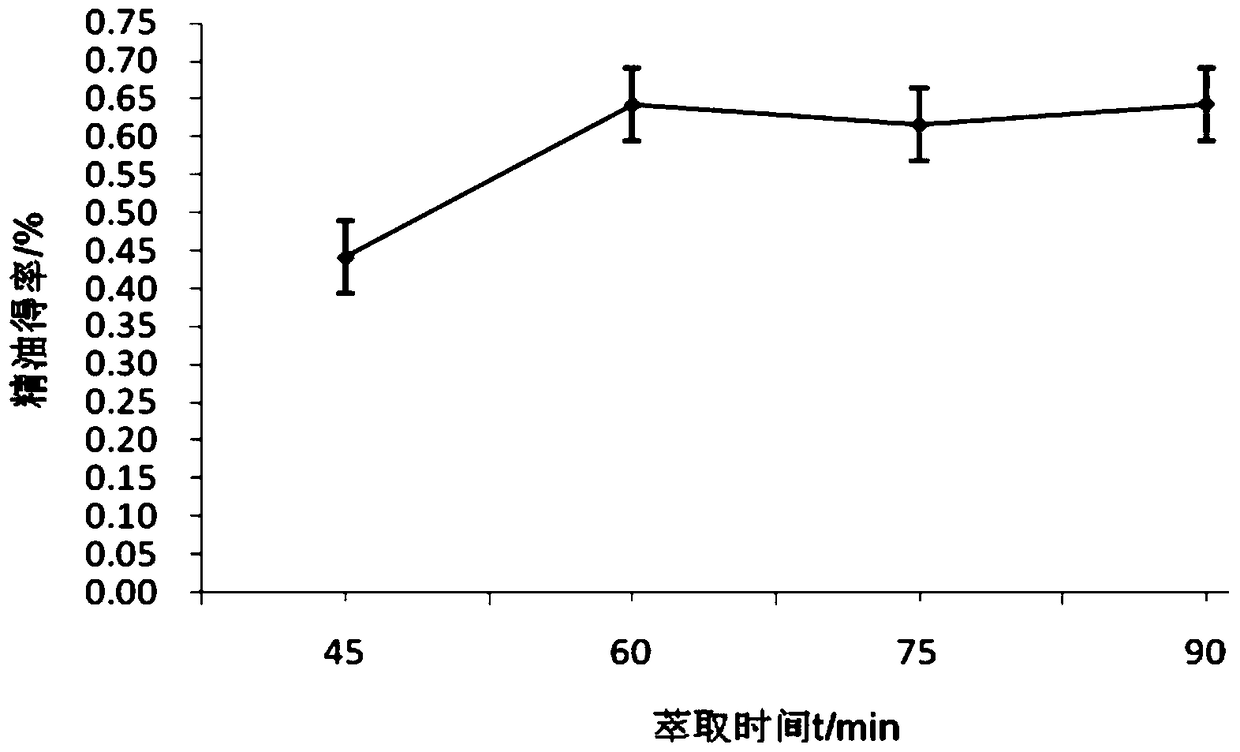

[0024] Embodiment 1 bergamot low-temperature continuous phase-change extraction process research experiment

[0025] According to the characteristics of the bergamot raw materials, the present invention continuously analyzes and determines and adjusts the process conditions. Follow the steps below:

[0026] S1. Bergamot (derived from Guangdong Zhancui Food Co., Ltd.) was crushed to an appropriate mesh size, dried at 50°C to make the moisture ≤ 13%, and bergamot powder was obtained;

[0027] S1. Weigh the bergamot powder obtained in S1 according to the bulk density requirements of different raw materials and put it directly into the extraction tank 1, pressurized by the high-pressure pump 7 to make the n-butane pass through the heat exchanger 8I, and enter the extraction tank 1 to determine its The extraction is carried out at the extraction temperature and pressure, and the solvent through the extraction tank 1 enters the analysis tank 2I with oil, where it is analyzed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com