Preparation technique of rose essential oil

A preparation process, a technology of rose essential oil, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of active ingredient damage, reduction of essential oil quality, rose essential oil head fragrance damage, etc., to reduce loss, improve quality, and oil output rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

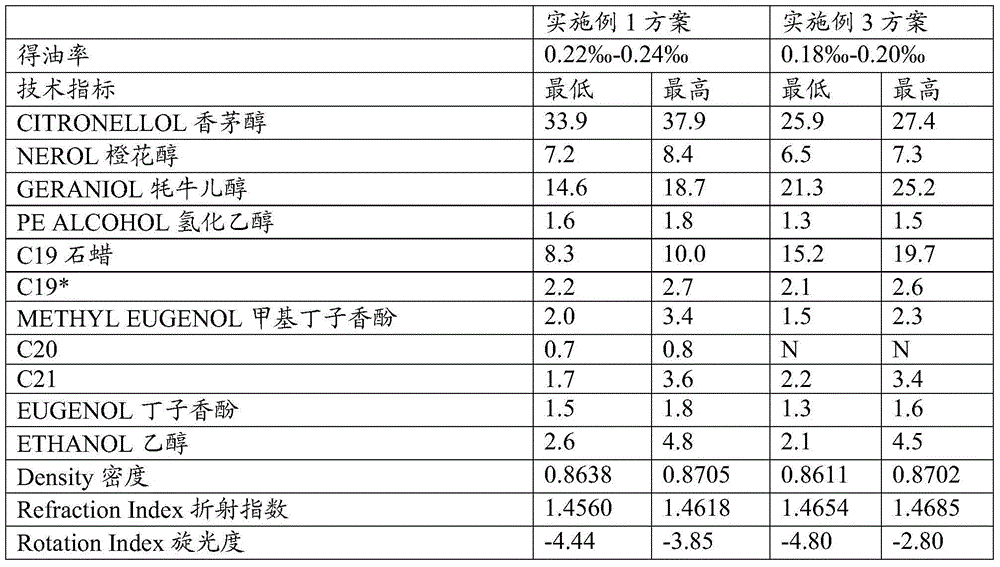

Embodiment 1

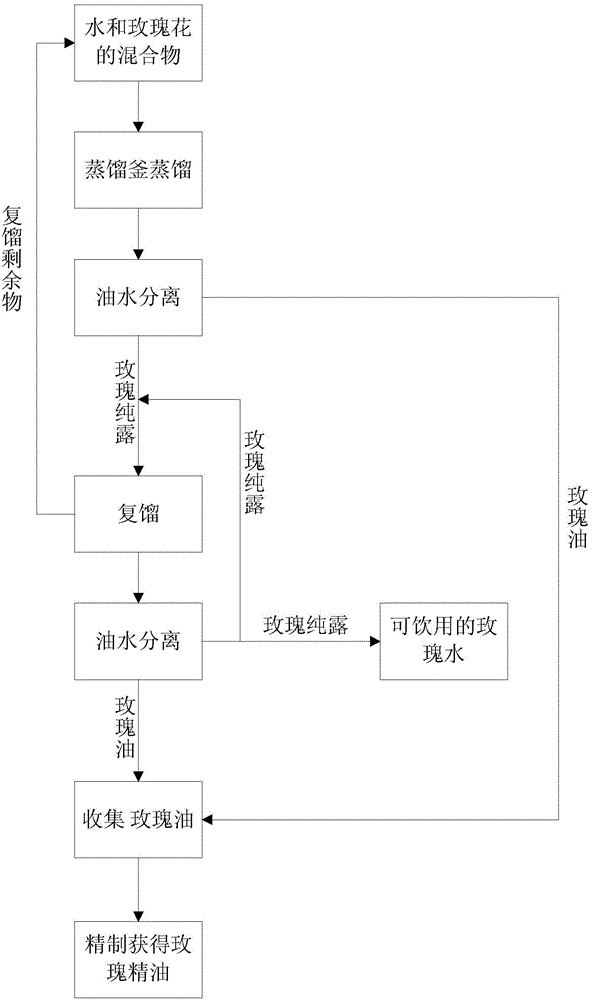

[0029] Embodiment 1: preparation process of the present invention

[0030] The mixture of rose flowers and water (rose flowers: water mass ratio = 1:4) is directly heated to 95°C through steam in the distillation kettle, and the steam pressure is maintained at 4-5kg / m 2 , and then stop the steam and change it to a heat coil outside the inner shell of the distillation kettle to heat the steam, and the steam pressure is maintained at 3-4kg / m 2 , reduce the temperature in the kettle and keep it at 90°C for distillation to obtain the mixture of rose oil and rose hydrosol and the distillation residue;

[0031] The mixture of rose oil and rose pure dew is separated, the rose oil is reserved, and the rose pure dew is heated by steam through a heat coil installed outside the inner shell of the distillation kettle, and the steam pressure is maintained at 3-4kg / m 2 , re-distilled at 90°C to obtain a mixture of rose oil and rose hydrosol and the residue of the re-distillation, separate ...

Embodiment 2

[0033] Embodiment 2: preparation process of the present invention

[0034] The mixture of rose flowers and water (rose flowers: water = 1:4) is directly heated to 98°C through steam in the distillation kettle, and the steam pressure is maintained at 4-5kg / m 2 , and then stop the steam and change it to a heat coil outside the inner shell of the distillation kettle to heat the steam, and the steam pressure is maintained at 3-4kg / m 2 , reducing the temperature in the kettle and maintaining the distillation at 92°C to obtain a mixture of rose oil and rose hydrosol and the distillation residue; the distillation residue extracts rose ketone to prepare rose flower body membrane;

[0035] The mixture of rose oil and rose pure dew is separated, the rose oil is reserved, and the rose pure dew is heated by steam through a heat coil installed outside the inner shell of the distillation kettle, and the steam pressure is maintained at 3-4kg / m 2 , re-distilled at 90°C to obtain a mixture of...

Embodiment 3

[0037] Embodiment 3: preparation process of the present invention

[0038] The mixture of rose flowers and water (rose flowers: water = 1:4) is directly heated to 96°C through steam in the distillation kettle, and the steam pressure is maintained at 4-5kg / m 2 , and then stop the steam and change it to a heat coil outside the inner shell of the distillation kettle to heat the steam, and the steam pressure is maintained at 3-4kg / m 2 , reducing the temperature in the kettle and maintaining the distillation at 93°C to obtain a mixture of rose oil and rose hydrosol and a distillation residue; extracting rose ketone from the distillation residue to prepare rose flower membranes;

[0039] The mixture of rose oil and rose pure dew is separated, the rose oil is reserved, and the rose pure dew is heated by steam through a heat coil installed outside the inner shell of the distillation kettle, and the steam pressure is maintained at 3-4kg / m 2 , re-distilled at 90°C to obtain a mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com