A method for preparing diamond-al composite material by extrusion impregnation

A composite material and diamond technology, applied in the field of preparing ultra-high thermal conductivity diamond-Al composite materials, can solve problems such as low diamond-Al preparation efficiency, and achieve the effects of improving interface bonding, avoiding coating oxidation, and reducing interface thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

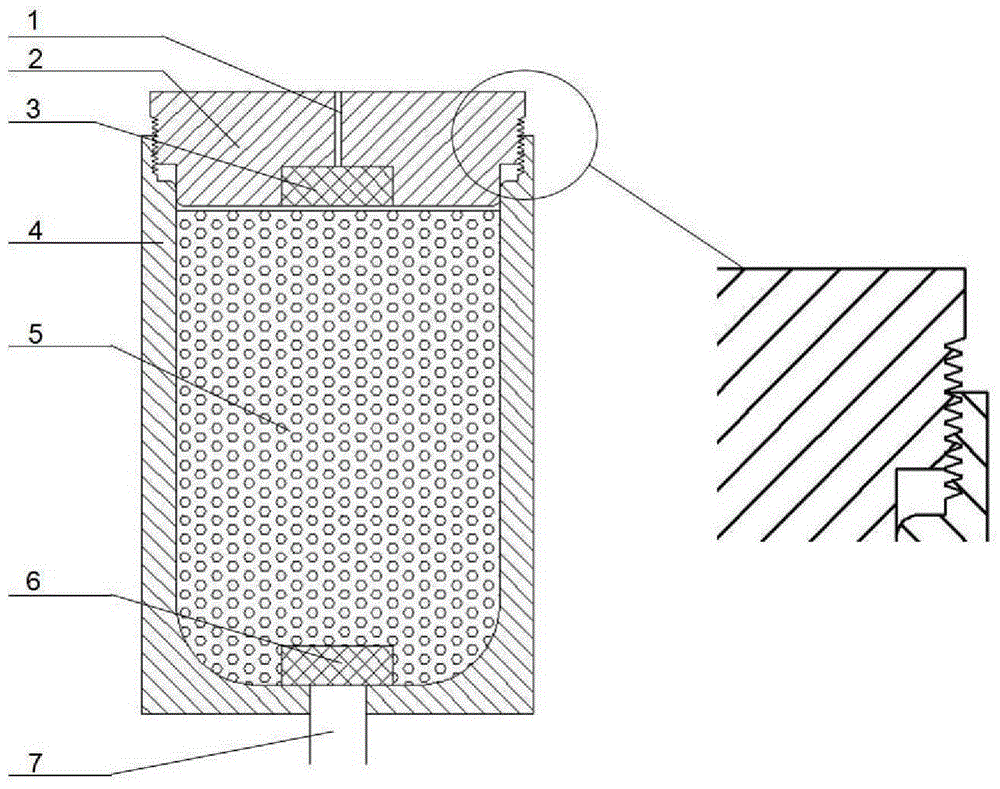

[0036] (1) Take a certain quality of diamond particles and aluminum alloy blocks, wherein the diamond is MBD4 type, the particle size is 180-250 μm (no coating on the surface), and the aluminum alloy composition is Al-7% Si (liquidus and solidus temperatures were 615°C and 577°C, respectively).

[0037] (2) Spray BN release agent on the inner surface of the mold cavity and upper cover, and then put a circular porous ceramic sheet (pore diameter 150 μm) into the mold cavity and upper cover. Fill the mold with diamond particles, keep the mold vertical and vibrate, so that the diamond particles can accumulate freely, and then screw on the upper cover (a gap of 1-2mm is reserved between the upper cover and the surface of the particle accumulation body).

[0038] (3) Preheat the mold to 650°C and keep it warm for 1h. Take out the mold and keep it in a vertical state, vibrate the mold again, and tighten the upper cover, so that the diamond particles are pressed and kept tightly pac...

Embodiment example 2

[0042] (1) Take a certain quality of diamond particles and aluminum alloy blocks, wherein the diamond is MBD4 type, the particle size is 125-180 μm (not coated on the surface), and the aluminum alloy composition is Al-12.5% Si (liquidus and solidus The temperature is 577°C).

[0043] (2) Spray the paint BN release agent on the inner surface of the mold cavity and the upper cover, and then put the circular porous ceramic sheet (pore diameter 100 μm) into the mold cavity and the upper cover. Fill the mold with diamond particles, keep the mold vertical and vibrate, so that the diamond particles can accumulate freely, and then screw on the upper cover (a gap of 1-2mm is reserved between the upper cover and the surface of the particle accumulation body).

[0044] (3) Preheat the mold to 610°C and keep it warm for 2h. Take out the mold and keep it in a vertical state, vibrate the mold again, and tighten the upper cover, so that the diamond particles are pressed and kept tightly p...

Embodiment example 3

[0048] (1) Weigh diamond particles and aluminum alloy blocks of a certain quality, wherein the diamond is MBD4 type, the particle size is 180-250 μm (no coating on the surface), and the aluminum alloy composition is Al-9% Si (liquidus and solidus temperatures were 600°C and 577°C, respectively).

[0049] (2) Spray BN release agent on the inner surface of the mold cavity and upper cover, and then put a circular porous ceramic sheet (pore diameter 150 μm) into the mold cavity and upper cover. Fill the mold with diamond particles, keep the mold vertical and vibrate, so that the diamond particles can accumulate freely, and then screw on the upper cover (a gap of 1-2mm is reserved between the upper cover and the surface of the particle accumulation body).

[0050] (3) Preheat the mold to 630°C and keep it warm for 1h. Take out the mold and keep it in a vertical state, vibrate the mold again, and tighten the upper cover, so that the diamond particles are pressed and kept tightly pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com