High-temperature sealing discharging device and method

A high-temperature sealing and unloading device technology, which is used in transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problem of lack of high-temperature sealing performance, and achieve the effect of good mechanical strength and good mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

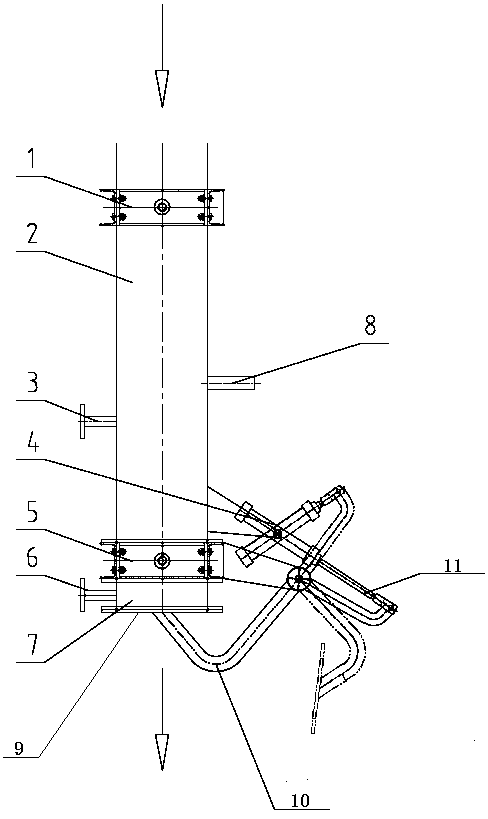

[0024] Such as figure 1 As shown, a high-temperature sealed unloading device is a kind of unloading device for emergency unloading of inflammable, explosive and easily oxidized materials in the transportation process. The bulk material temperature is required to be high temperature resistant to 750°C or above, and it needs not to be in contact with the air when unloading.

[0025] A high-temperature sealed unloading device includes a first chute 2, a second chute 7 and a flap device 4, the first chute 2, the second chute 7 and the flap device 4 are made of stainless steel 316L, and the stainless steel 316L It has excellent high temperature performance, can operate under the condition of 800 ℃ for a long time, and can ensure the mechanical strength of the unloading device. When the first chute 2, the second chute 7 and the plate turning device 4 are produced, all welding positions are welded with special stainless steel high-temperature-resistant electrodes to ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com