Manufacturing device of oxygen-containing gaseous fuel

A gas fuel and manufacturing device technology, applied in the direction of adding non-fuel substances to fuel, charging system, combustion engine, etc., can solve the problems of tank rupture, danger, leakage of combustible gas or liquid catalyst, etc., to avoid insufficient or Excessive, increased safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

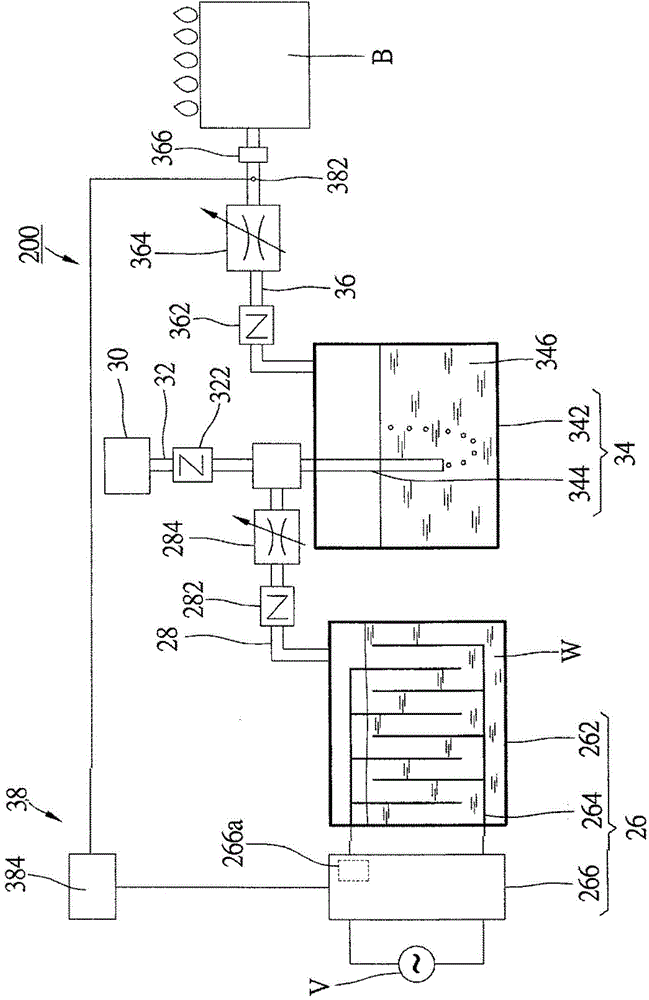

[0015] Please refer to figure 2 As shown, an oxygen-containing gaseous fuel manufacturing device 200 according to a preferred embodiment of the present invention includes an electrolysis unit 26 , a gas supply unit 30 , a mixing tank 34 and a feedback control unit 38 . In this embodiment, the oxygen-containing gas fuel production device 200 is connected to a burner B.

[0016] The electrolysis unit 26 includes an electrolysis tank 262 , a plurality of electrodes 264 and a power supply 266 . The electrolytic tank 262 is used to accommodate the water W to be electrolyzed, the electrode 264 is disposed in the electrolytic tank 262 , and the power supply 266 is electrically connected to the electrode 264 . The power supply 266 receives the electric energy of an AC power supply V, and converts it into direct current and applies it to the electrode 264. The power supply 266 is controlled by the feedback control unit 38 to change the voltage applied to the electrode 264, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com