Water receivers for shoe presses, shoe press units and paper machines

A technology of shoe press and water receiving tank, which is applied in the direction of paper machine, press part, paper making, etc., can solve the problems of reducing the speed of paper machine and low production efficiency, and achieve the effect of improving production efficiency, low cost and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

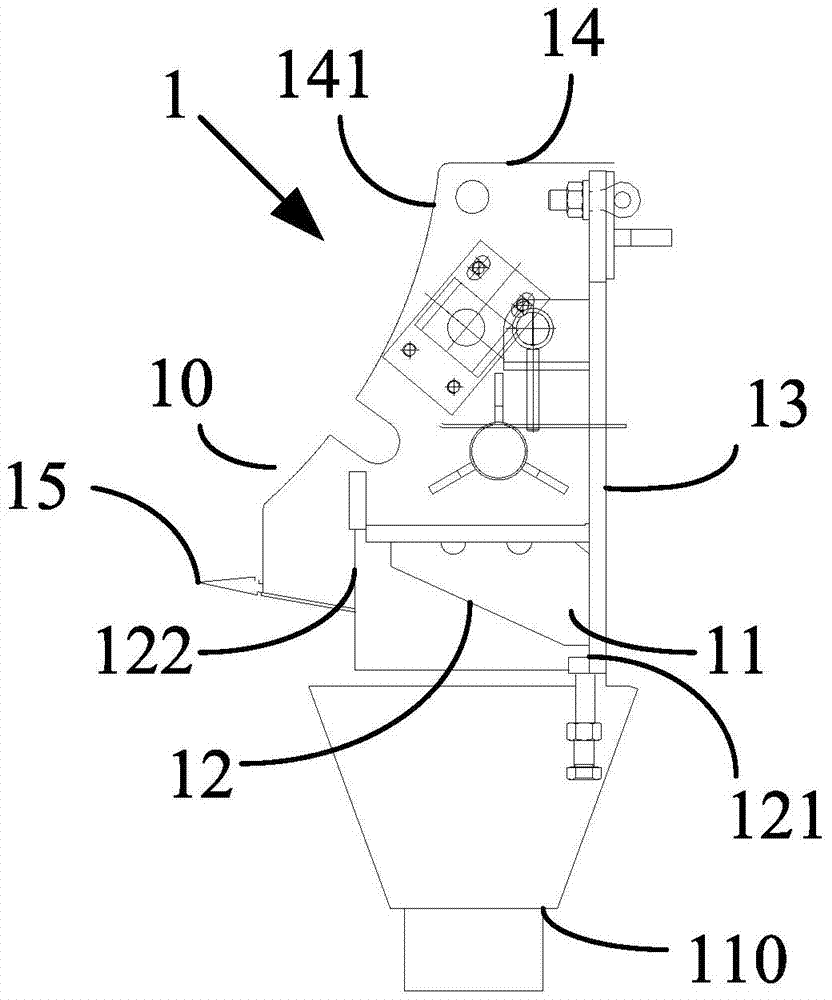

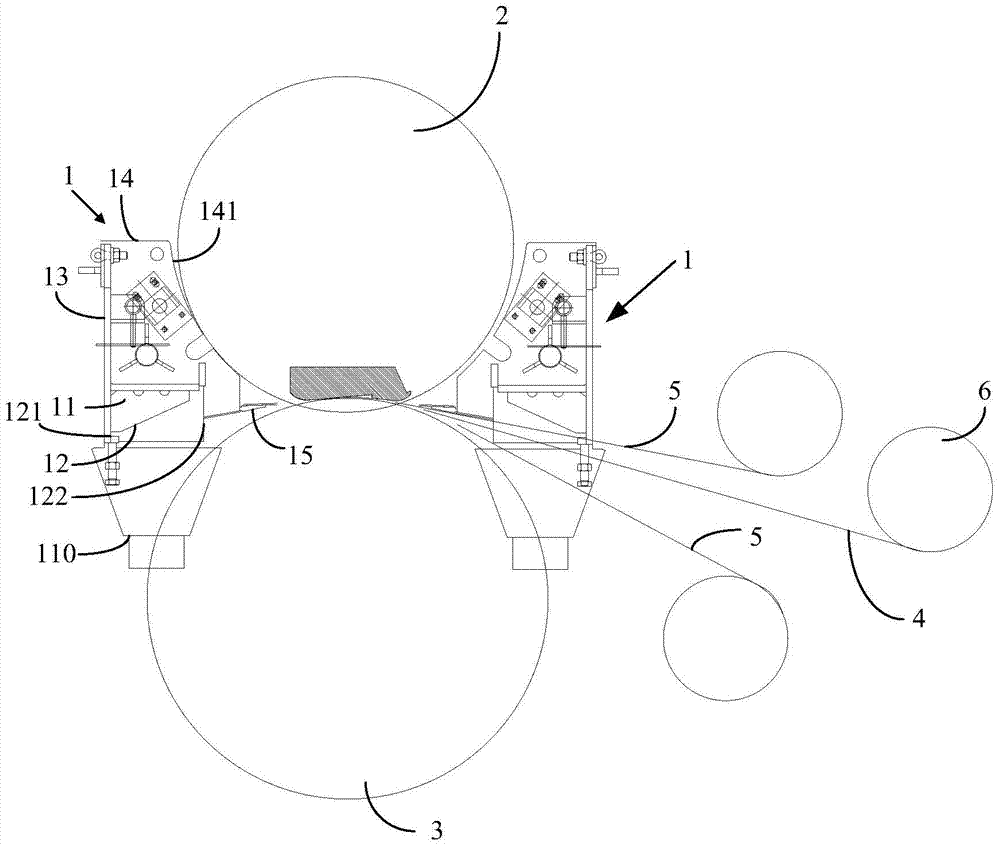

[0020] refer to figure 1 , is a schematic cross-sectional structure diagram of the water receiving tank used in the shoe press according to the present invention.

[0021] The present invention provides a water receiving tank for shoe pressing, the water receiving tank 1 is strip-shaped, and the water receiving tank 1 is provided with a water receiving opening 10 extending along its length direction, which is used to receive splashed water during shoe pressing , the water receiving opening 10 extends along the length direction of the water receiving tank, so that during the shoe press process, the water splashed in the length direction of the nip can fall into the water receiving tank 1 from the water receiving opening 10, and the two ends of the water receiving tank 1 are provided with There is a drain port 11 for discharging the water in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com