Method for regeneration of particle filter of internal combustion engine, corresponding controller and vehicle

A particle filter and vehicle technology, applied in engine control, fuel injection control, internal combustion piston engine, etc., can solve the problems of shortened oil change interval, increased component wear, lean oil, etc., to reduce noise troubles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

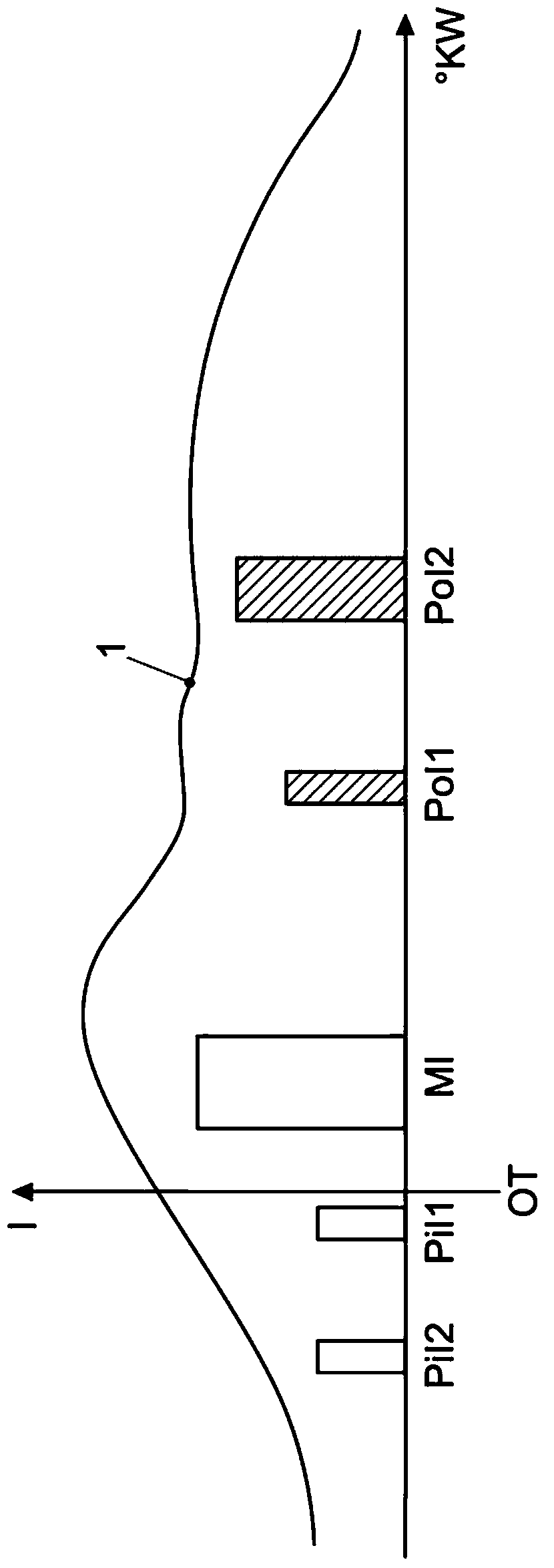

[0035] In order to increase the temperature of the exhaust gases, the injection is postponed overall to a later crank angle region relative to the normal operation of the internal combustion engine, e.g. figure 1 shown. Here, the two pre-injections or pilot injections Pil1 and Pil2 take place almost before top dead center (corresponding to a crank angle of 0°), and the main injection MI takes place in the crank angle range of 0° to −14°. Followed by two subsequent injections Pol1 and Pol2, it is used to increase the temperature in the engine and increase the temperature of the exhaust gas. It can be seen that the combustion curve 1 is delayed or prolonged by the post-injections Pol1 , Pol2 into the later crank angle range.

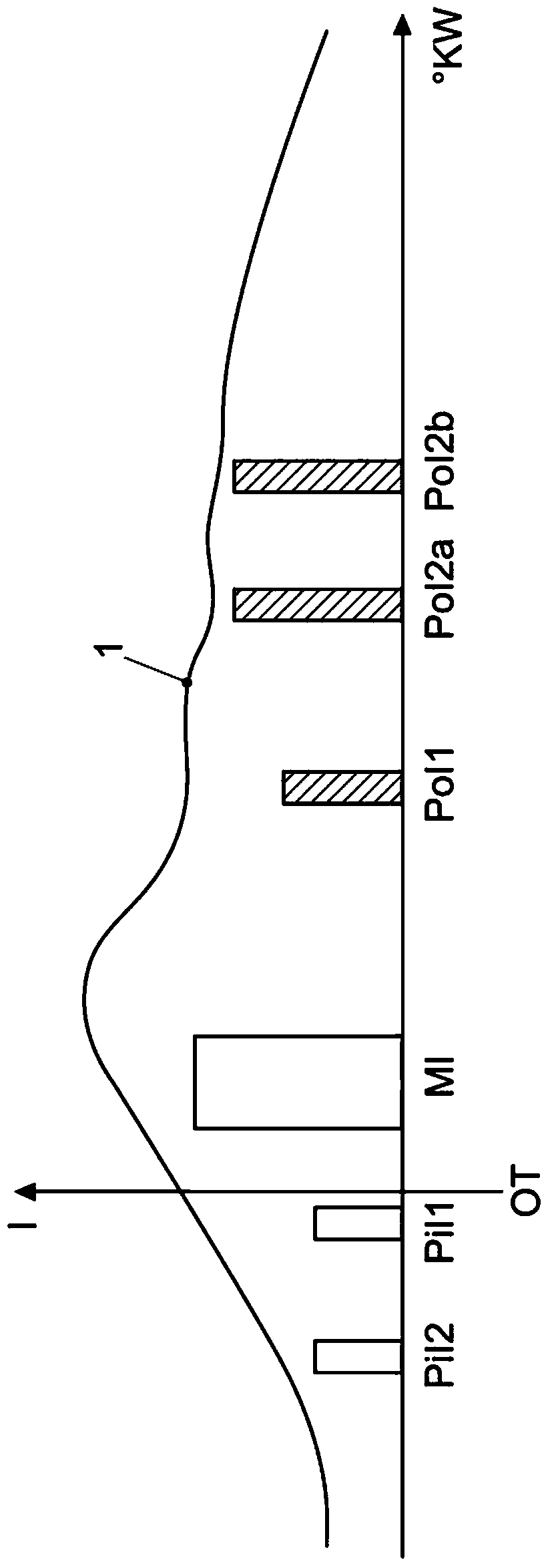

[0036] According to the invention, the second post-injection Pol2 is now divided into several post-injections Pol2a, Pol2b, as it is used for figure 2 implementation form. In other words, the fuel quantity injected according to the prior art only by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com