Energy saver with condensate water guide flow plate

A technology of economizer and deflector, applied in the directions of feed water heater, preheating, steam generation, etc., can solve problems such as pollution, and achieve the effects of increasing the heating area, preventing falls, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

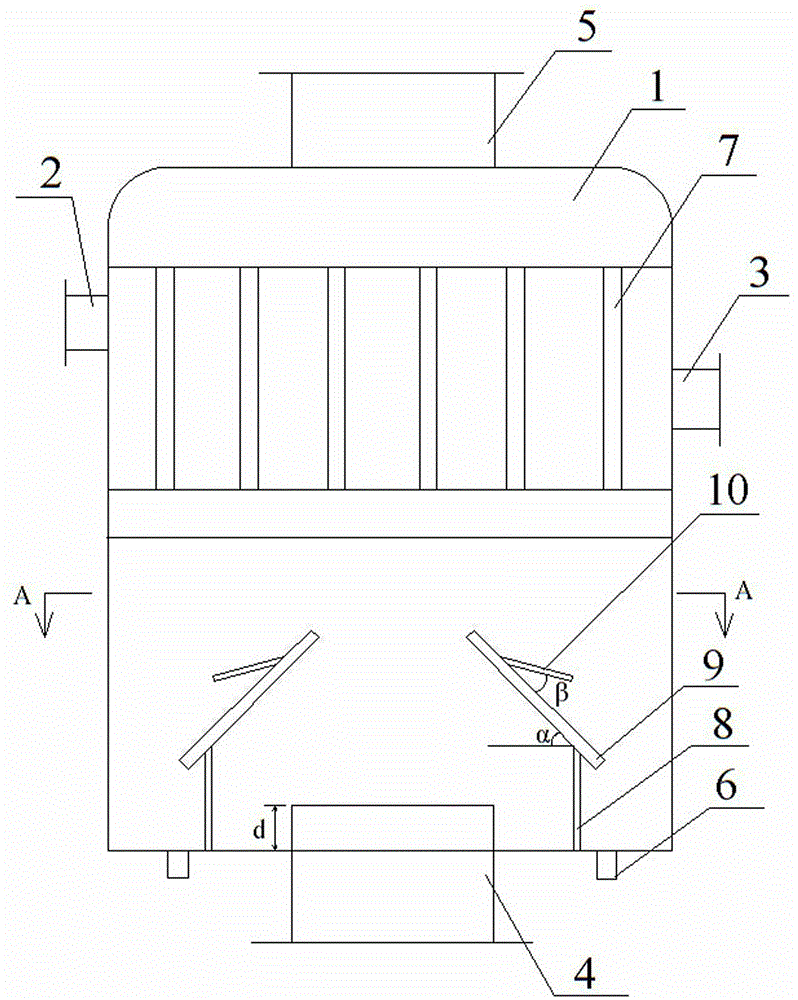

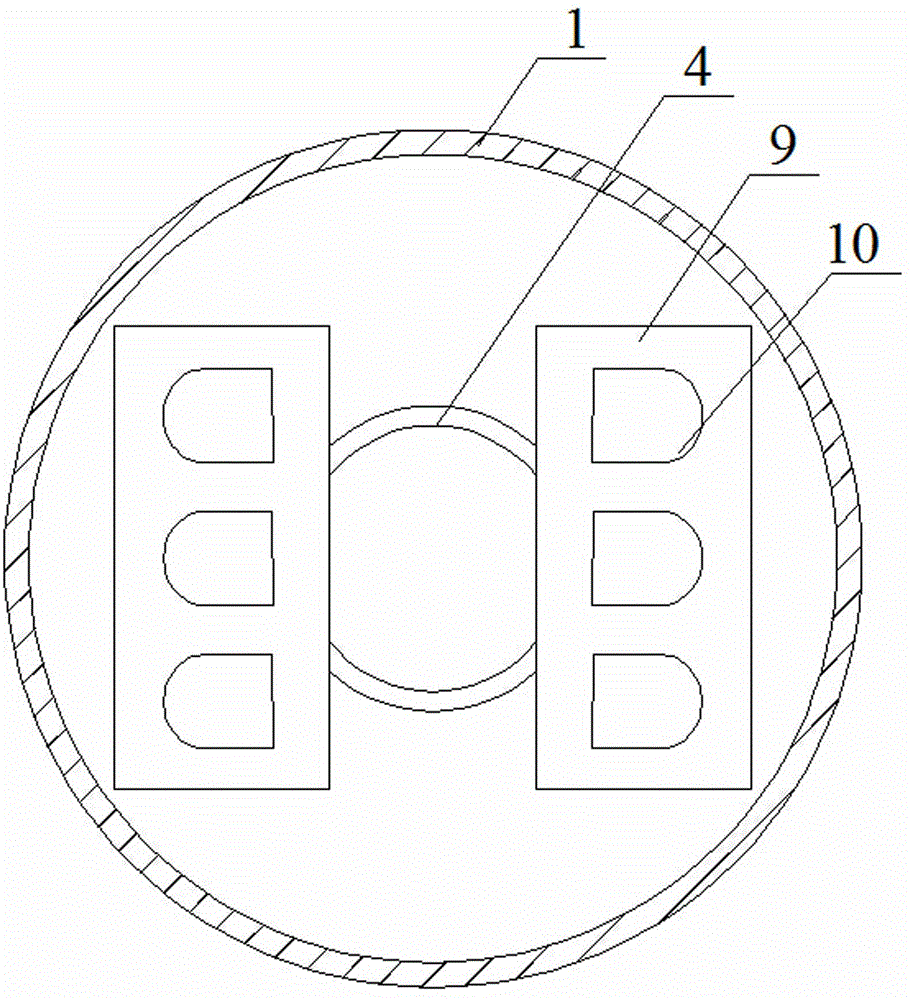

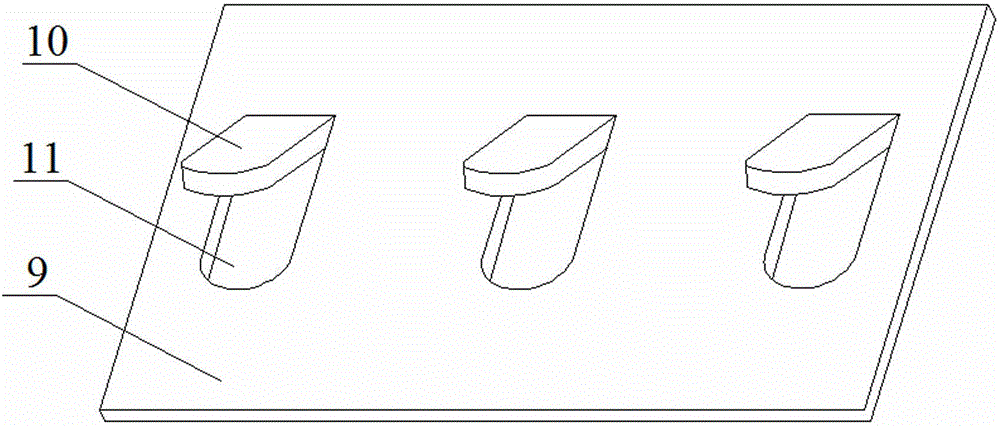

[0016] Such as figure 1 , figure 2 and image 3 As shown, the economizer with condensed water deflector in this embodiment includes an economizer 1, the upper side of the economizer is provided with a water inlet 2, and the other side is provided with a water outlet 3, and the lower end of the economizer is provided with There is a flue gas inlet 4, the upper end of which is provided with a flue gas outlet 5, and drain ports 6 are symmetrically arranged on both sides of the flue gas inlet, the upper part of the economizer chamber is provided with a smoke pipe group 7, and the lower part of the economizer chamber is provided with The flue gas in the flue gas inlet of the flue gas diversion device enters the smoke pipe group through the flue gas diversion device and is discharged through the flue gas outlet; the flue gas diversion device includes a support rod 8 fixed at the bottom of the economizer, and the support A flue gas diverter plate 9 is arranged on the rod, and a co...

Embodiment 2

[0021] In this embodiment, the included angle α between the flue gas diverter plate and the bottom surface of the economizer is 50°; the included angle β between the condensed water diverter plate and the plane where the flue gas diverter plate is located is 20°; the flue gas inlet The height d extending into the economizer is 100mm, and the rest of the technical solutions are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com