Device and method for automatically scanning test tube bar code

An automatic scanning and test tube technology, applied in the direction of electromagnetic radiation induction, etc., can solve the problem of inability to automatically scan test tube barcodes in batches, and achieve the effect of convenient scanning of test tube barcodes, simple and convenient operation, and not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

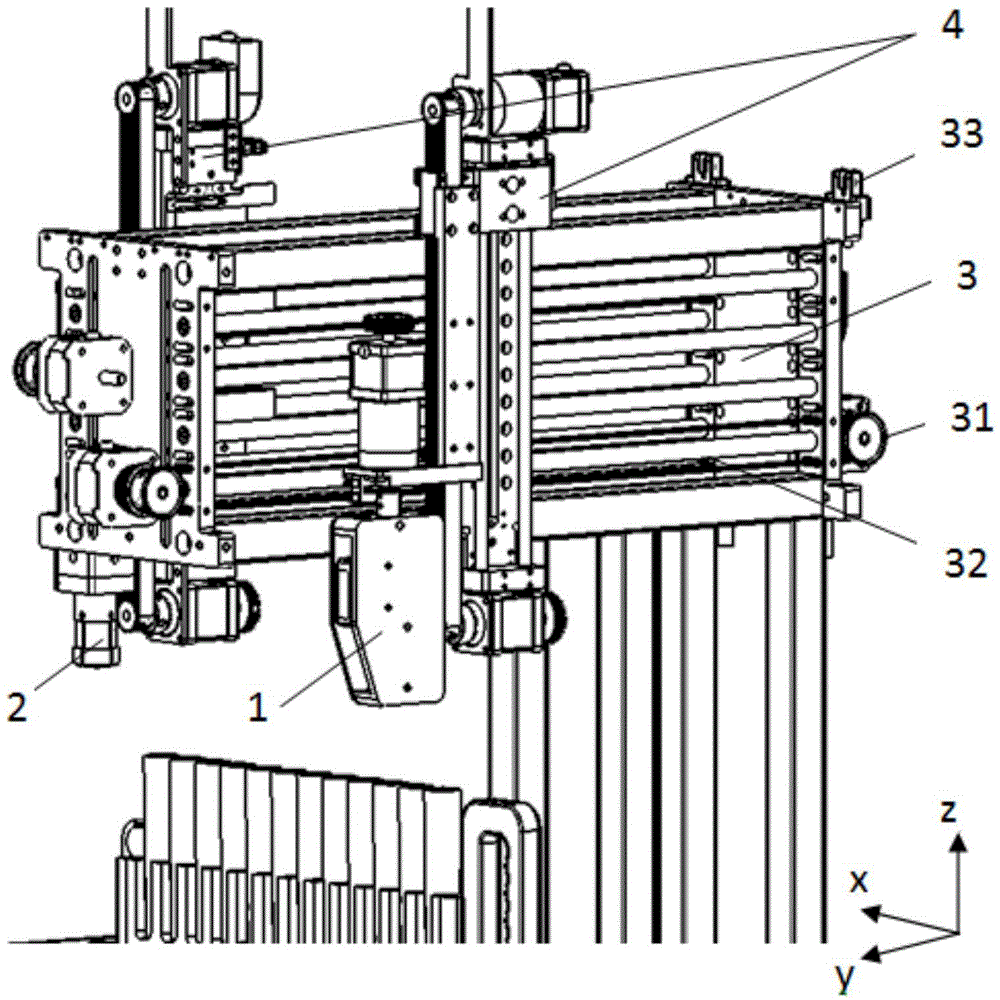

[0054] Such as figure 2 As shown, an automatic scanning device for test tube barcodes includes a scanning device 1, a tube revolving device 2, and an equipment main body. The main body of the equipment includes a first driving device that drives the tube revolving device 2 to move in the vertical direction, that is, Z-direction motion, and a driving tube revolving device 2 The second driving device that moves in the horizontal direction is the Y-direction movement.

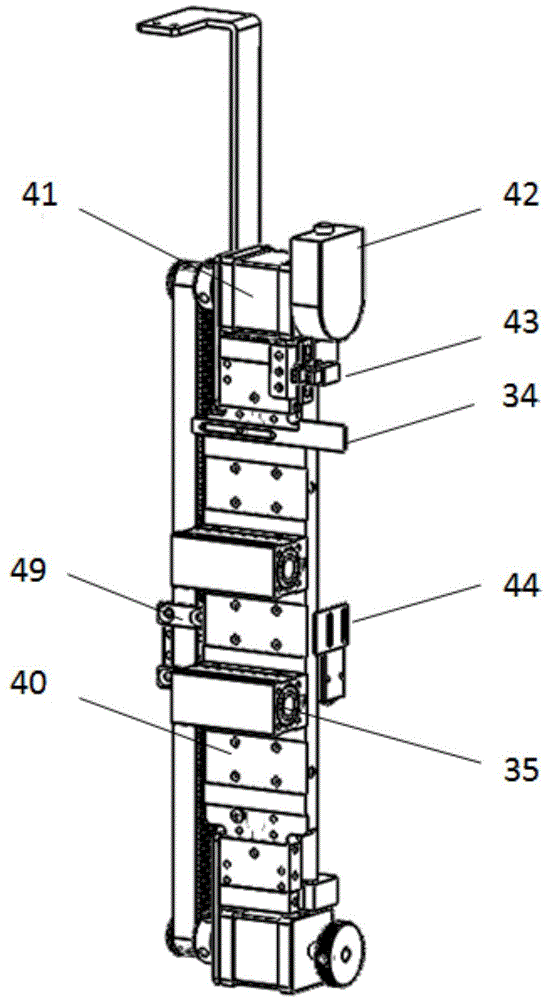

[0055] Such as figure 2 , image 3 , Figure 4 As shown, the first driving device includes a Z-direction bracket 4 installed on the main body of the equipment, which includes a Z-direction bracket body 40, a Z-direction drive motor 41, and a positioning unit 42 mounted on the motor shaft such as an encoder and a Z-direction positioning device 43, Z-direction reset baffle 44, motor mounting frame 45, lifting rail seat 46, Z-direction optical axis guide 47, Z-direction slider 48 containing linear bearings, belt pressi...

Embodiment 2

[0066] On the basis of the first embodiment, the equipment is provided with a third driving device for vertical movement and a fourth driving device for horizontal movement similar to the first driving device and the second driving device. Different carriers are designed on the Z-direction slider 48 on the first driving device and the third driving device according to requirements, and suitable motors are selected according to the load. The scanning device 1 and the rotating tube device 2 are both carrier mechanisms on the Z-direction bracket 4.

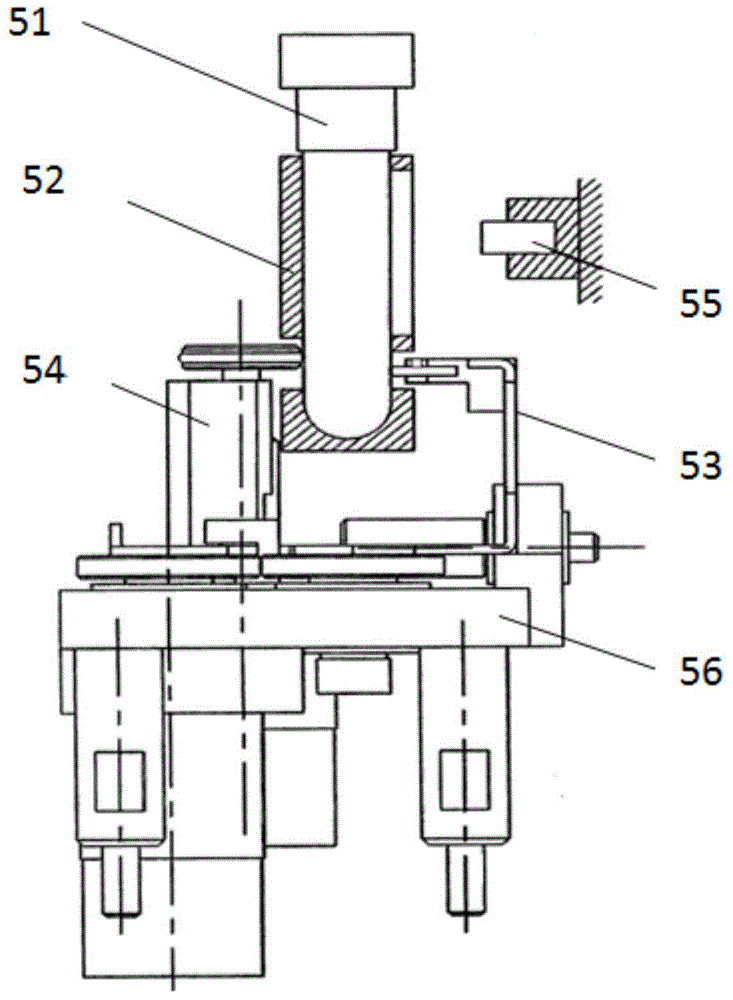

[0067] Such as figure 2 , Figure 5 with Image 6 As shown, the scanning device 1 includes a bar code gun mounting frame 10, a bar code gun drive motor 11 such as a planetary reduction stepper motor, a rotating motor seat 12, a bar code gun box 13, a bar code gun positioning plate 14, and a bar code gun positioning device 15. The bar code gun box includes a bar code gun shaft 16, a detection unit 17 for detecting a test tube, such as a ...

Embodiment 3

[0070] Such as Figure 15 As shown, a method for scanning the barcode of a test tube, using the device of Embodiment 1 or Embodiment 2, includes the following steps:

[0071] S1: The detection unit detects the target test tube; if the test tube is detected, the scanning device scans the test tube;

[0072] S2: If the barcode is not scanned, the tube rotating device picks up the upper part of the target test tube through the tube clamp, moves the target test tube horizontally and vertically into the position to be scanned, and rotates the target test tube for the scanning device to scan the target test tube After scanning the barcode on the test tube, the tube stripping device returns the test tube to its original position.

[0073] Preparatory work before scanning the test tube barcode: Before the test tube rack is ready to enter the detection channel, the Y-direction drive motor 31 is driven by the timing belt, and the Z-direction bracket 4 where the scanning device 1 is located is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com