Mechanical property prediction method of cemented filling material

A technology for cementing filling materials and performance prediction, which is applied in prediction, biological neural network model, data processing application, etc., to achieve the effect of simple operation process, reliable results and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

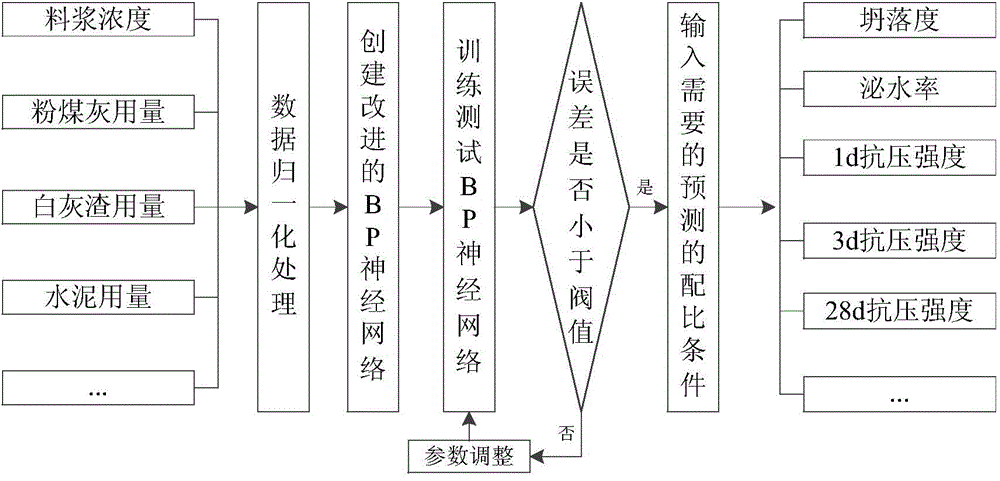

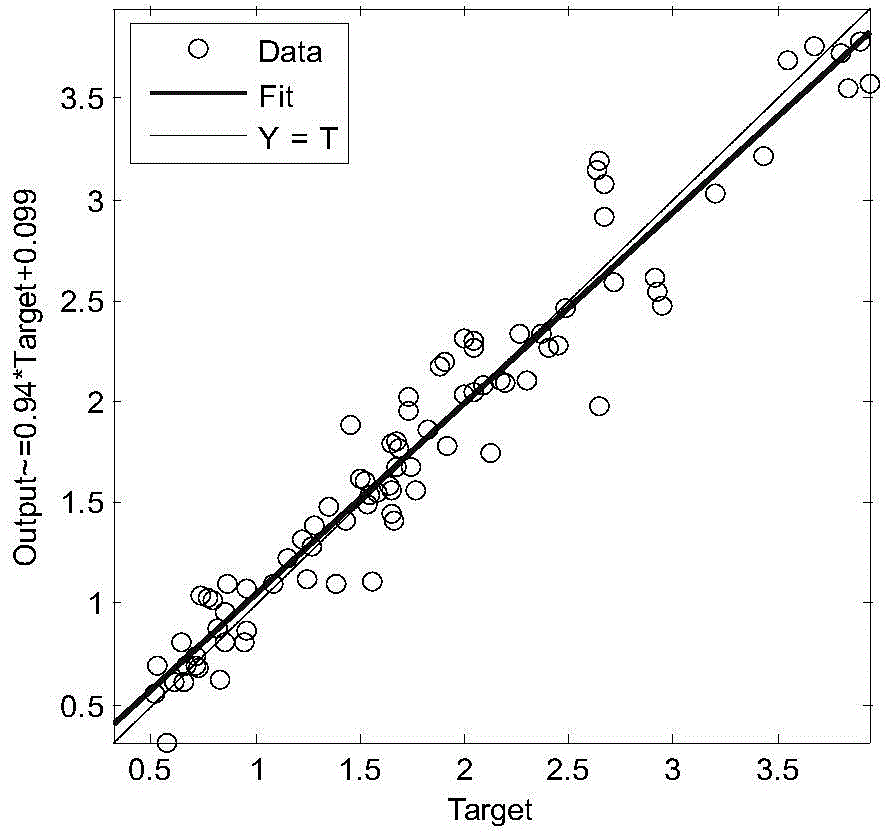

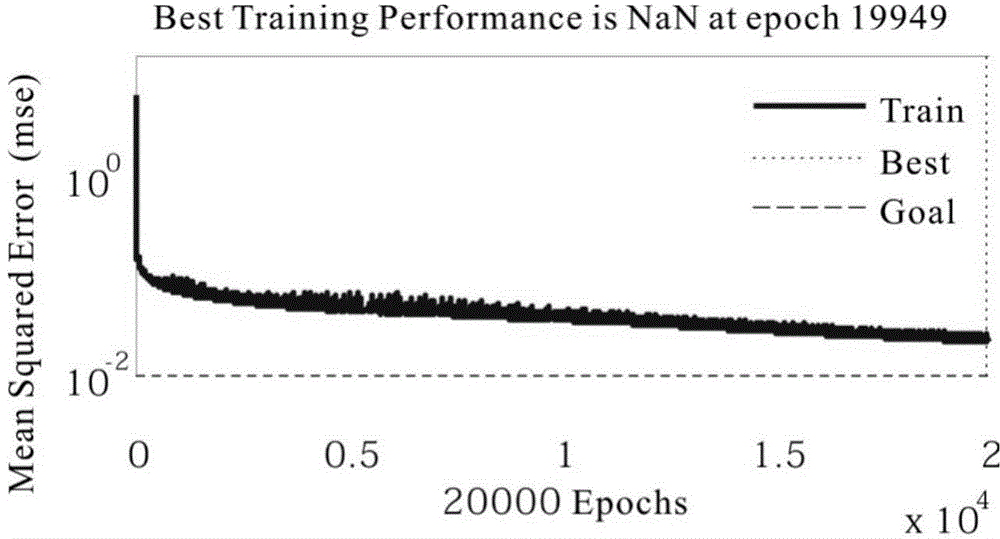

[0019] Embodiment 1: The prediction method is based on the BP neural network that introduces additional momentum method and adaptive learning rate improvement, trains and tests the network through the sample data obtained through laboratory experiments, and then inputs the conditions that need to be predicted to obtain the corresponding Mechanical property value; specifically include the following steps:

[0020] a. For the factors affecting the mechanical properties of cemented filling materials, the cemented filling materials are the concentration of slurry, the amount of fly ash, the amount of lime slag and the amount of cement; laboratory experiments are carried out with different ratios to obtain the filling under different ratios of influencing factors Material mechanical property value, described influencing factor is slump, bleeding rate and the compressive strength of each age; Obtain training sample and test sample; Each proportioning value of mechanical property valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com