Low-frequency piezoelectric vibration energy collector based on Helmholtz effect and manufacture process thereof

A technology of energy harvester and piezoelectric vibration, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motor, generator/motor, electrical components, etc., to achieve the effect of wide frequency band, low frequency and high efficiency conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

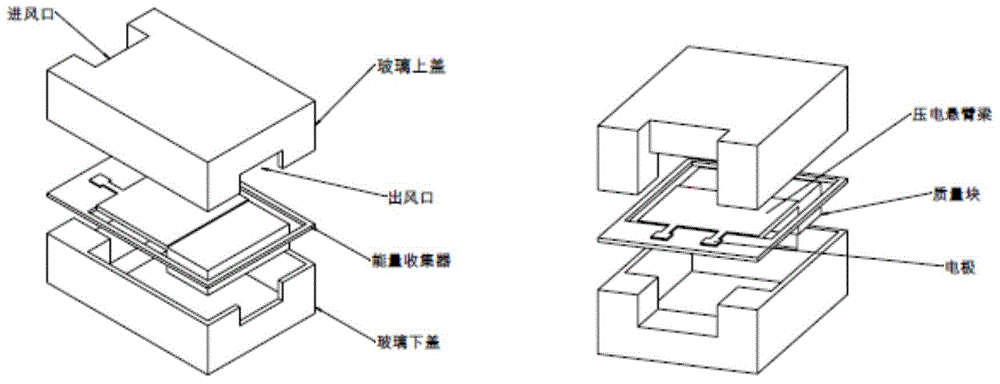

[0033] The low-frequency piezoelectric vibration energy harvester based on the Helmholtz effect proposed by the present invention mainly utilizes the input and output chambers connected to microchannels of specific geometric dimensions to realize the Helmholtz pressure resonance effect. By coupling the Helmholtz resonance and the so-called vortex shedding, the pressure vibration is further enhanced, so a wide frequency bandwidth can be achieved at low frequencies.

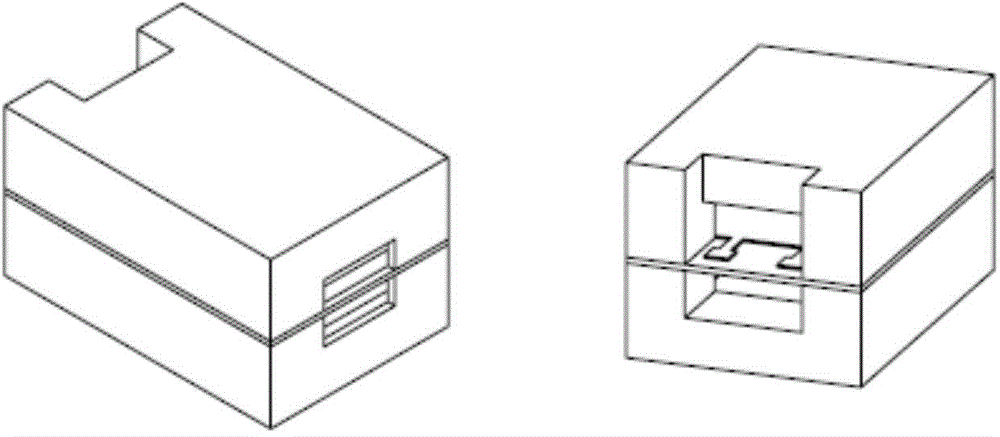

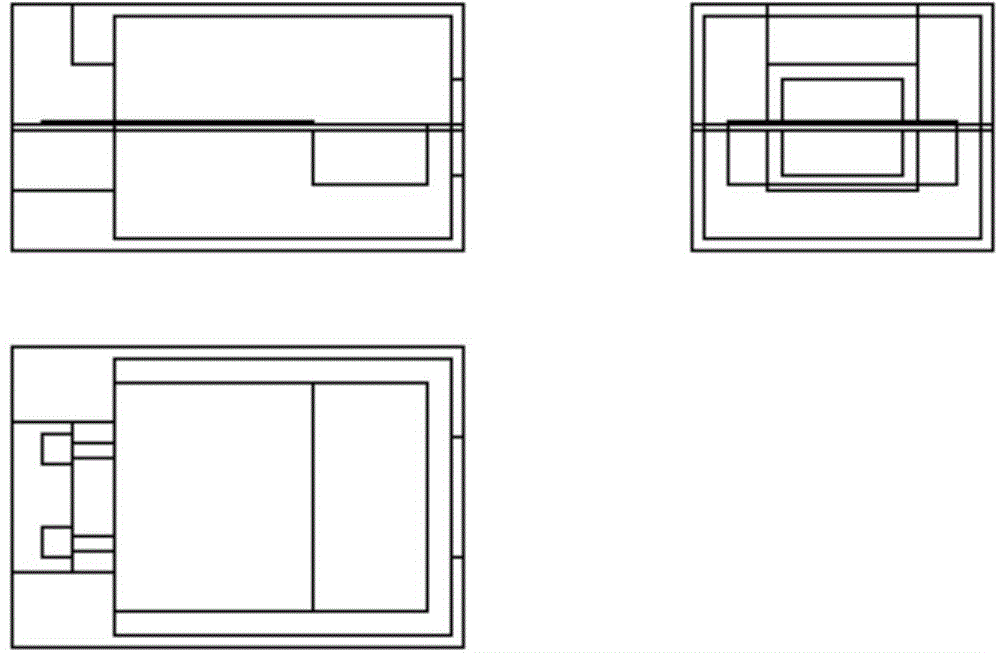

[0034] Figures 1 to 3 It is a structural schematic diagram of the energy harvester of the present invention. As shown in the figure, the energy harvester mainly includes: a glass upper cover, a glass lower cover, and an energy conversion unit; the glass upper cover and the glass lower cover are combined up and down to form a Helmholtz resonance cavity, the energy conversion un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com