Electronic cigarette liquid and preparing method thereof

A technology of e-cigarette liquid and raw materials, applied in tobacco, tobacco processing, application, etc., can solve the problems that affect the user's real experience of e-cigarette liquid, cannot satisfy different groups of people, and cannot achieve aroma experience, etc., to achieve convenient operation and preparation The method is simple and the taste will not be sour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

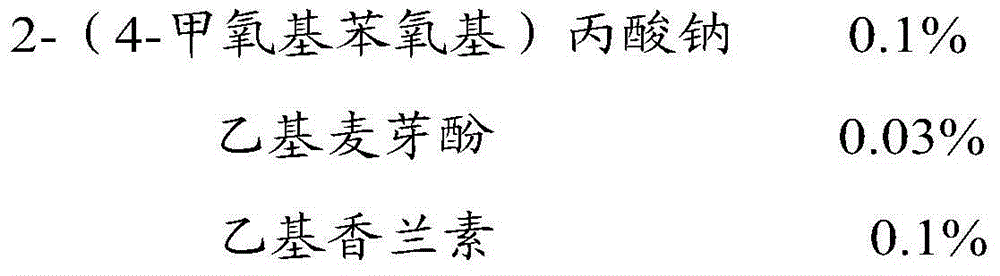

[0027] The raw material composition of e-cigarette liquid is calculated by mass percentage (total 10kg):

[0028]

[0029]

[0030] The preparation method of electronic cigarette liquid is as follows:

[0031] Add the above raw materials into a food-grade sealed tank in sequence, stir and mix evenly, then soak for 120 minutes at a temperature of 30°C, then filter impurities, sterilize with ultraviolet light, and pack into small packages.

Embodiment 2

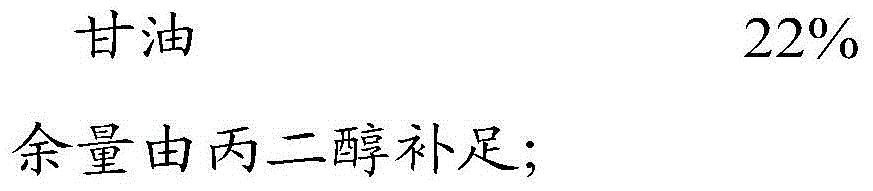

[0033] The raw material composition of e-cigarette liquid is calculated by mass percentage (total 10kg):

[0034]

[0035] The preparation method of electronic cigarette liquid is as follows:

[0036] Add the above raw materials into a food-grade sealed tank in turn, stir and mix evenly, control the stirring rate at 200rad / min, then soak for 480min at a temperature of 40°C, heat up to 60°C for 20min, then cool down to room temperature, filter Impurities and ultraviolet rays are sterilized, and then packed into small packages.

Embodiment 3

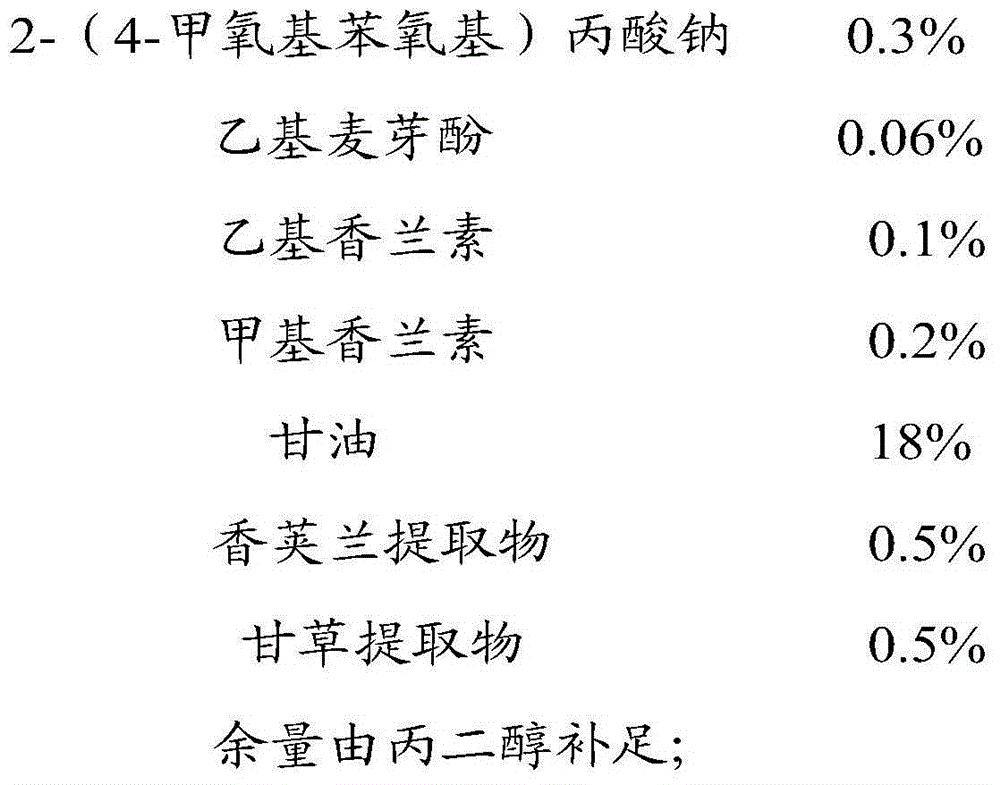

[0038] The raw material composition of e-cigarette liquid is calculated by mass percentage (total 10kg):

[0039]

[0040]

[0041] The preparation method of electronic cigarette liquid is as follows:

[0042] Add the above raw materials into a food-grade sealed tank in turn, stir and mix well, control the stirring rate at 300rad / min, then soak for 320min at a temperature of 35°C, heat up to 70°C for 25min, then cool down to room temperature, filter Impurities and ultraviolet rays are sterilized, and then packed into small packages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com