Low-cost quick solidifying method for composite material

A composite material, rapid curing technology, applied in the field of composite material molding, can solve the problems of high production cost, low energy consumption, slow temperature rise, etc., to achieve the effect of low heating energy consumption, accurate control, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

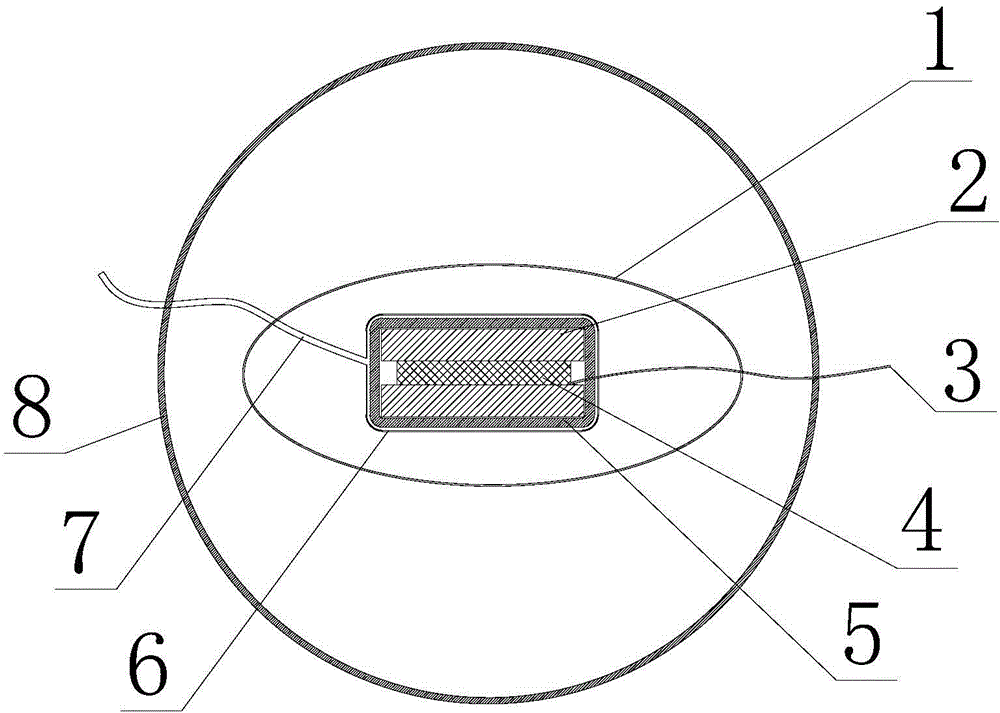

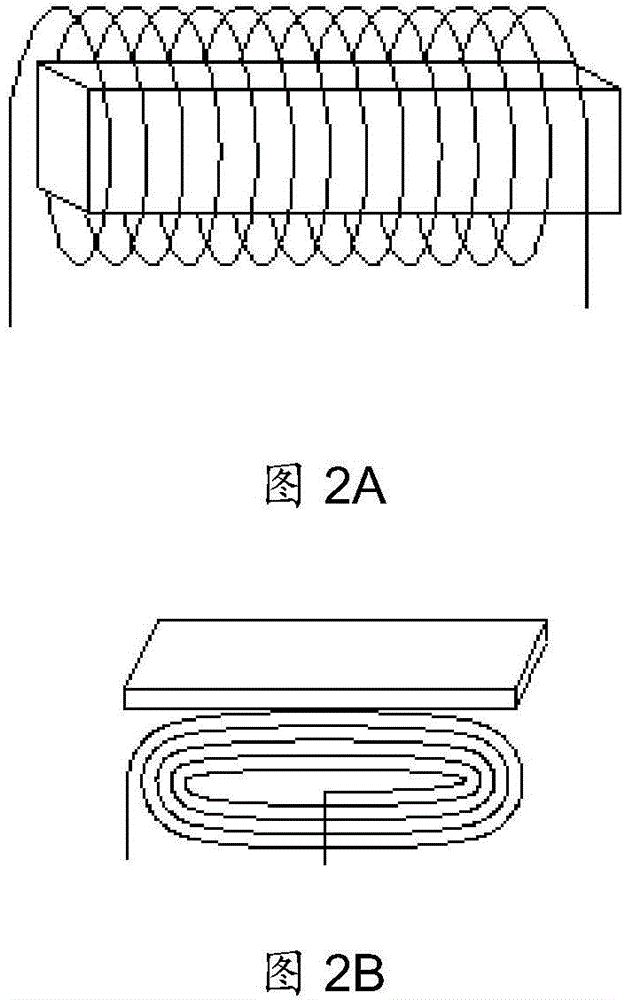

[0052] Intermediate frequency electromagnetic induction heating and curing molding temperature 300 ℃ ~ 320 ℃ carbon fiber polyimide panel, the details are as follows:

[0053] The pre-cured composite material is carbon fiber / polyimide plate, with a length of 400mm, a width of 260mm, and a thickness of 2mm.

[0054] The mold is processed by steel plate, one piece on the upper and lower sides, the length is 420mm, the width is 300mm, and the thickness is 12mm.

[0055] The breathable and thermal insulation layer adopts a 2-layer structure, and the inner layer material can withstand high temperatures exceeding 320°C. The upper and lower planes of the forming mold 2 are made of heat-insulating rock wool boards, with a thickness of 5mm. The narrow parts around the mold are made of glass fiber felt. The solid thickness is not less than 5mm to ensure that the steel mold is not exposed. The outer material is made of ordinary polyester non-woven air felt, which is heat-resistant to 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com