Full steel radial ply tire on-line code-scanning, weighing and automatic conveying system positioned behind X-ray device

A radial tire, automatic conveying technology, applied in mechanical conveyors, conveyors, transportation and packaging, etc., can solve the problems of tire landing pollution, unadvanced process, high labor intensity, etc., to reduce labor intensity, strong intelligence, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below according to the drawings and embodiments.

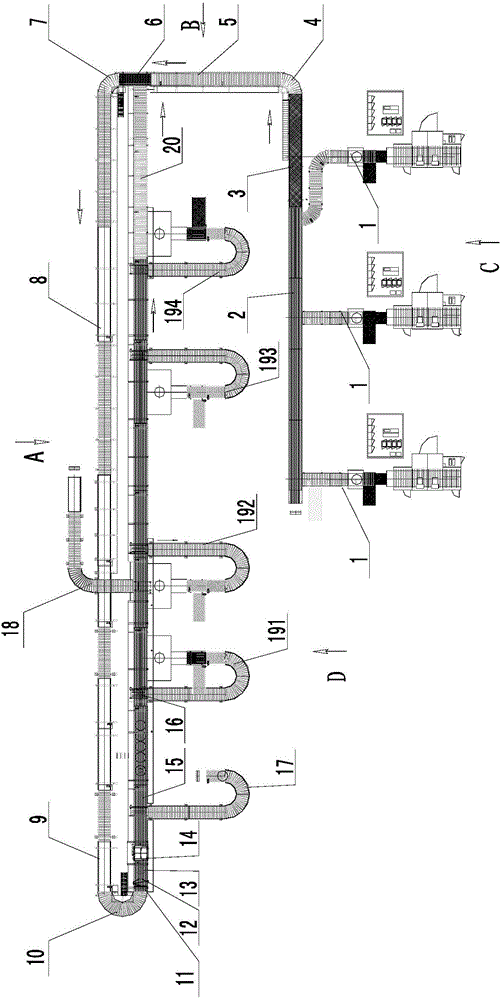

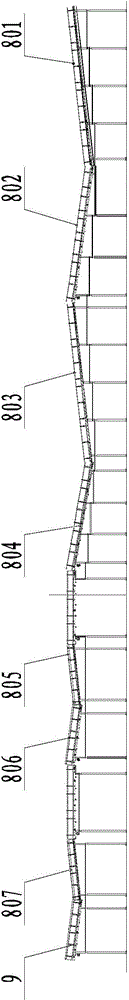

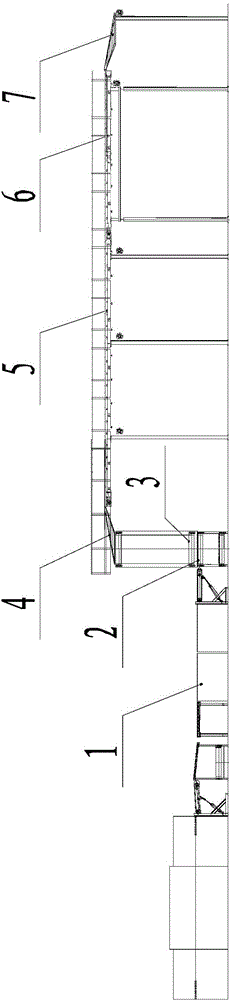

[0037] figure 1 It is a top view structure schematic diagram of the tire return circulation system located on the all-steel conveying line of the present invention. In the present invention, the tire return circulation system located on the all-steel conveying line includes sequentially connected: a collection module belt 2, a climbing conveyor belt 3, Turning roller table 4, horizontal conveying roller table 5, connecting module belt 6, turning roller table 7, tire conveying and storage roller table group 8, sorting system, two-way module belt 15, tire pushing device 16.

[0038] For each link:

[0039] The summary module belt 2 is used for summarizing the tires inspected by a plurality of X-ray detection inspection machines 1 .

[0040] The assembly module 2 belt includes a plurality of assembly sub-module belts connected in sequence, each assembly sub-module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com