A kind of microwave ceramic dielectric material, preparation method and application

A technology of microwave ceramics and dielectric materials, which is applied in waveguide-type devices, electrical components, connecting devices, etc., can solve the problems that restrict the development of microwave ceramic dielectric materials, poor signal-to-noise ratio in microwave frequency bands, and large power consumption, and achieve superior microwave performance. , high quality factor, high Q value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

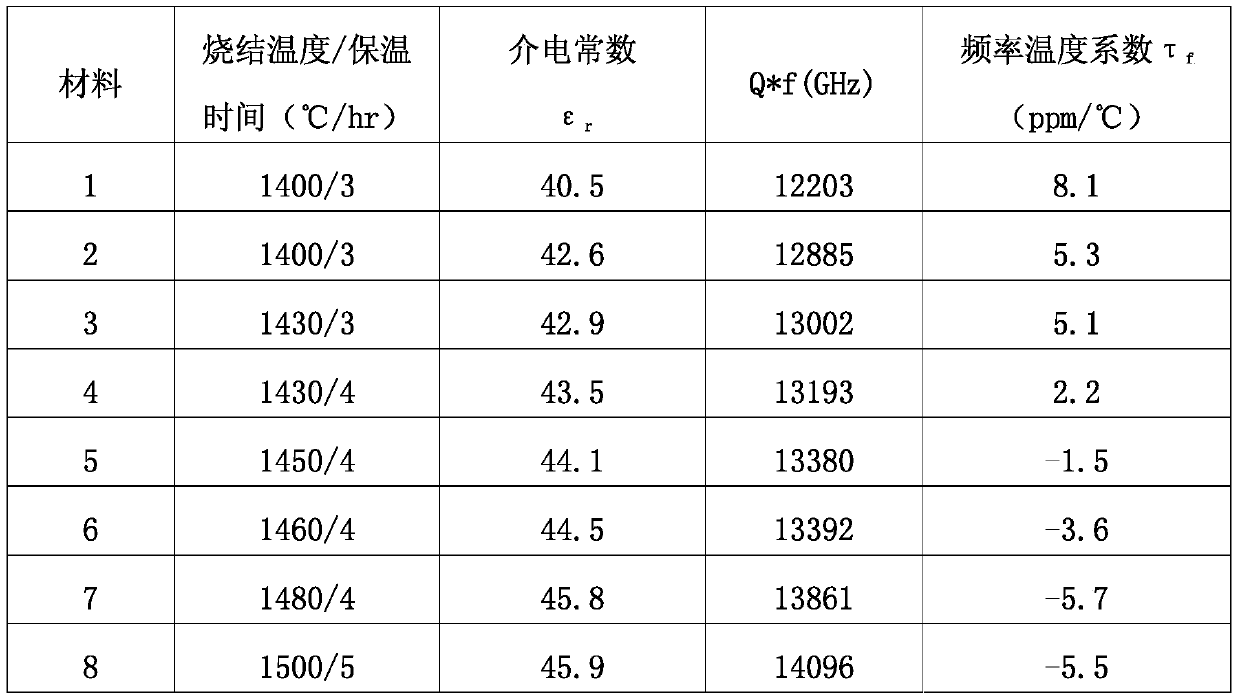

Examples

Embodiment 1

[0020] Embodiment 1: Preparation of microwave ceramic dielectric material

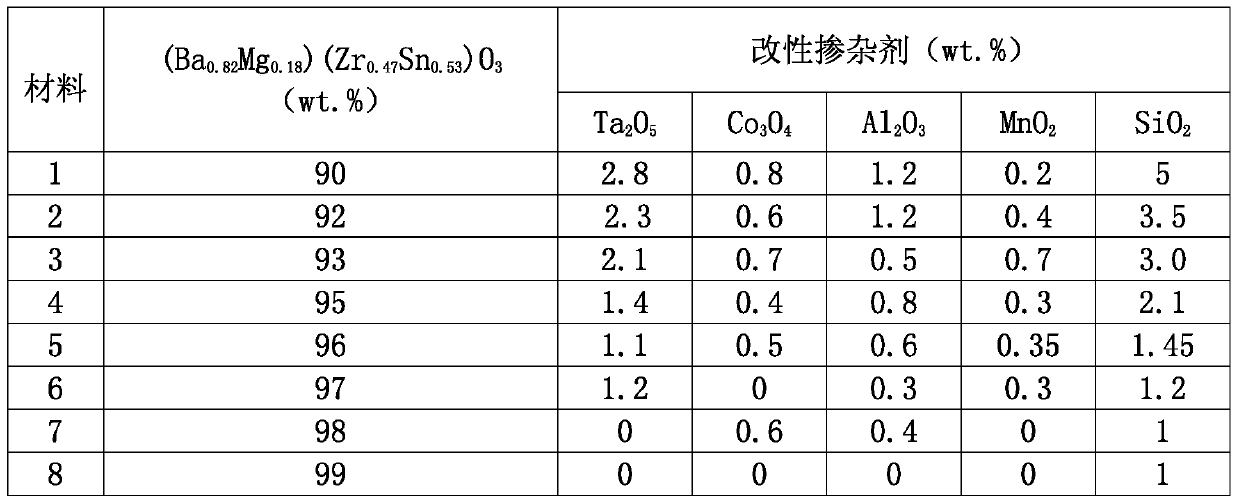

[0021] Raw materials: see Table 1

[0022] Preparation method: the steps are as follows:

[0023] Step 1: Synthesis of the main crystal phase: BaCO 3 , MgO, ZrO 2 and SnO 2 Be raw material, when x=0.82, when y=0.47, according to structural formula (Ba 0.82 Mg 0.18 )(Zr 0.47 sn 0.53 )O 3 The composition of the composition is carried out batching, and the prepared mixed material is put into the ball mill jar that zirconia ball is equipped with in advance, adds deionized water, ball mills for 15 hours, and after the discharge is dried, it is pre-calcined at 1300°C for 4 hours to obtain the (Ba 0.82 Mg 0.18 )(Zr 0.47 sn 0.53 )O 3 main crystalline material.

[0024] Step 2: In the above (Ba 0.82 Mg 0.18 )(Zr 0.47 sn 0.53 )O 3 The modified dopants shown in Table 1 were added to the main crystal phase, and zirconia balls and deionized water were used as milling media for ball milling for 20 ...

Embodiment 2

[0033] Embodiment 2: Preparation of microwave ceramic dielectric material

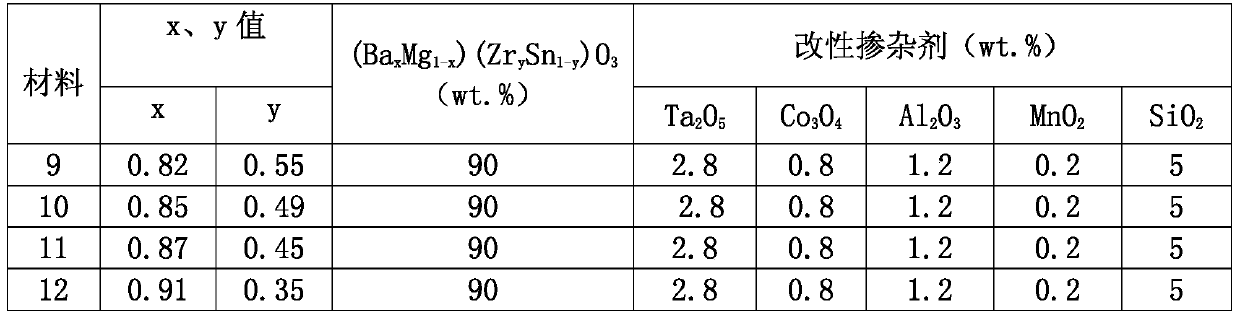

[0034] Raw material: see table 3

[0035] Preparation method: the steps are as follows:

[0036] Step 1: Synthesis of the main crystal phase: BaCO 3 , MgO, ZrO 2 and SnO 2 Prepare ingredients for the raw materials, see Table 3 for the specific formula composition, put the prepared mixture into a ball mill tank pre-installed with zirconia balls, add deionized water, ball mill for 15 hours, and pre-calcine at 1300°C for 4 hours to obtain the main crystal phase material.

[0037] Step 2: Add the modified dopant with the same composition as shown in Table 3 to the above-mentioned main crystal phase, and use zirconia balls and deionized water as the grinding medium, and ball mill for 20 hours.

[0038] Step 3: The ball-milled slurry in step 2 is discharged and dried, then added with a PVA binder to granulate, and molded under a pressure of 20 MPa to obtain a green body.

[0039] Step 4: Set the green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com