MHFPI type high temperature resistant epoxy matrix resin for carbon fiber cable core and preparation method thereof

A technology of epoxy matrix and epoxy resin, which is applied in the field of polymer materials, can solve problems such as unsatisfactory heat resistance, and achieve low viscosity, high reactivity, and good interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 36.6 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane, 41.0 grams (0.1 moles) of 2,2-bis[4-(3-aminophenoxy)benzene Base] propane and 520 grams of N,N-dimethylacetamide were added to the reaction kettle, and after stirring and dissolving at room temperature, 31.0 grams (0.1 moles) of 3,3',4,4'-tetracarboxydiphenyl ether di Anhydride, after stirring and reacting for 0.5 hours, add 19.6 grams (0.2 moles) of maleic anhydride, continue to stir and react for 0.5 hours, add 385 grams of acetic anhydride and 0.3 gram of pyridine, after stirring and reacting for 1 hour at 100 ° C, add 520 grams of methanol and 520 grams of ethanol was stirred at a high speed, filtered, the mother liquor was recovered, the filter cake was washed with 520 grams of acetone, and vacuum-dried at 70° C. for 8 hours to obtain 115.4 grams of MHFPI polyimide resin, which was designated as MHFPI-1.

Embodiment 2

[0045] 3.66 grams (0.01 moles) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane, 4.1 grams (0.01 moles) of 2,2-bis[4-(4-aminophenoxy)benzene Base] propane, 8.0 grams (0.04 moles) of 3,4'-diaminodiphenyl ether, 100 grams of N,N-dimethylacetamide and 100 grams of N-methyl-2-pyrrolidone were added to the reaction kettle, at room temperature After stirring and dissolving, add 3.2 g (0.01 mol) of 3,3',4,4'-tetracarboxybenzophenone dianhydride and 10.4 g (0.02 mol) of 2,2-bis[4-(3,4- Dicarboxyphenoxy) phenyl] propane dianhydride, after stirring for 0.5 hours, add 5.9 grams (0.06 moles) of maleic anhydride, continue stirring for 0.5 hours, add 200 grams of acetic anhydride and 1.3 grams of triethylamine, at 60 After stirring and reacting at ℃ for 2 hours, add 175 grams of methanol, stir at a high speed, filter, recover the mother liquor, wash the filter cake with 400 grams of acetone, and dry it in vacuum at 90 degrees Celsius for 5 hours to obtain 32.8 grams of MHFPI polyimide ...

Embodiment 3

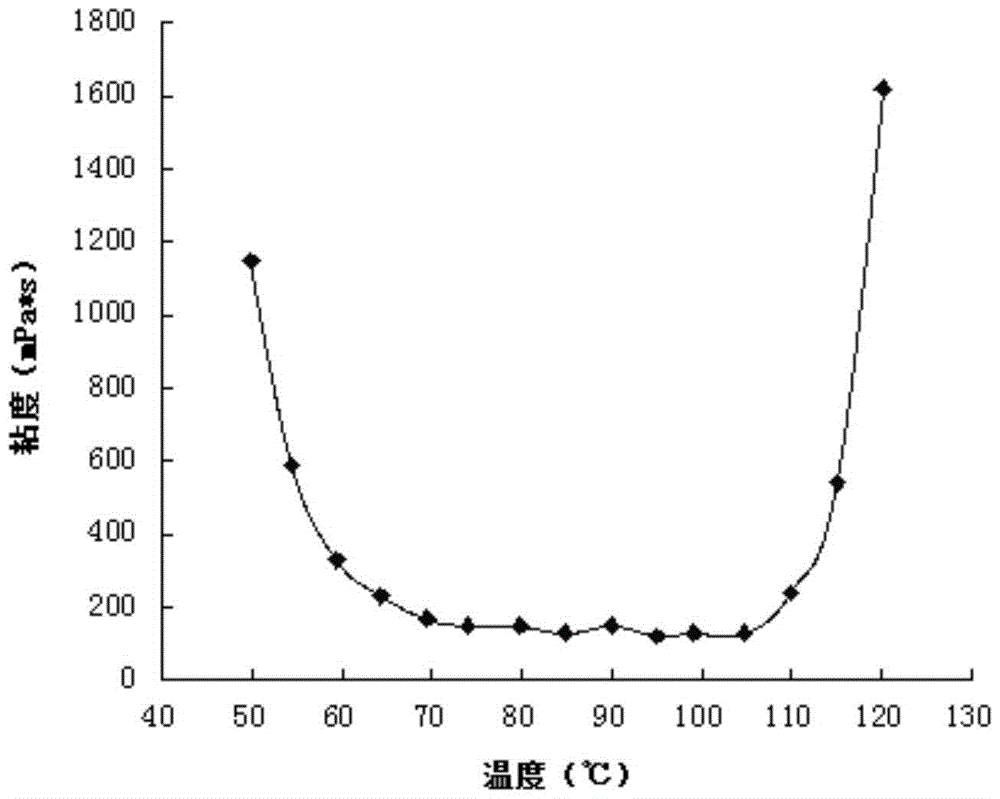

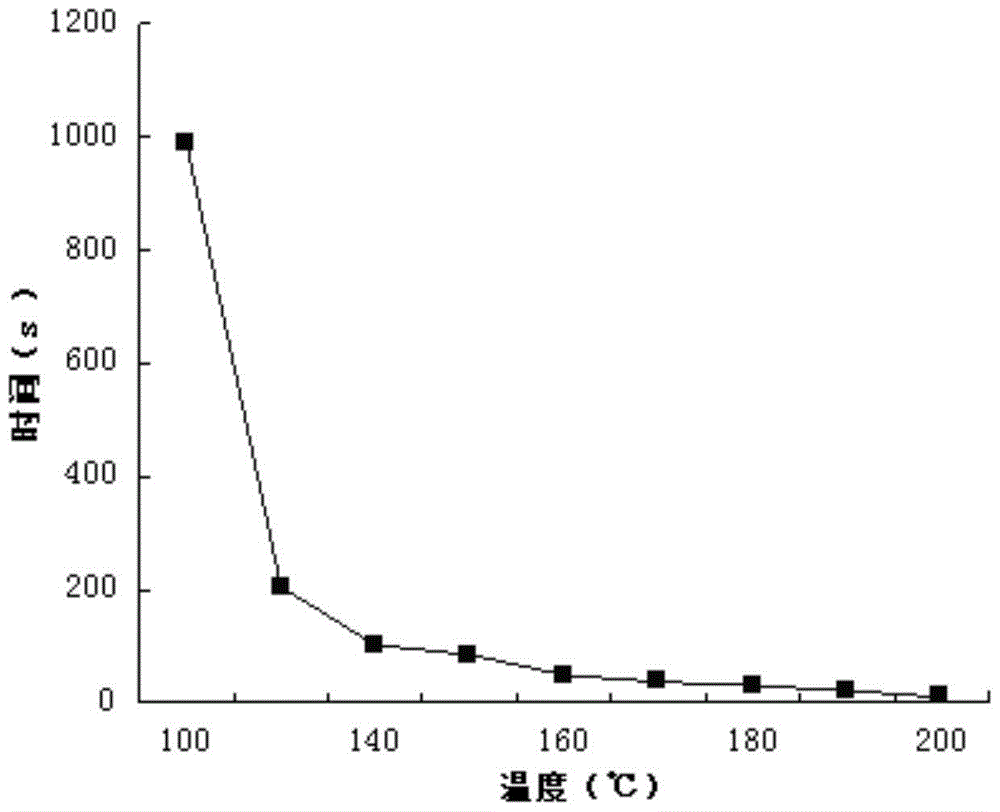

[0047] Add 100.0 grams of N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin into the reaction kettle, stir, heat up to 80°C, add 1.0 grams of MHFPI- 1 Polyimide resin, stirred and reacted at 80°C for 1 hour, cooled to below 90°C, added 20.0 grams of hydrogenated bisphenol A epoxy resin and continued to stir and reacted for 1 hour, cooled to below 60°C, added 100.0 grams of methyl tetra Hydrophthalic anhydride and 1.0 gram of aluminum acetylacetonate are stirred and mixed uniformly to obtain 322.0 gram of MHFPI type high temperature resistant epoxy matrix resin for carbon fiber cable core, denoted as M-1, and its viscosity-temperature curve is as follows figure 1 As shown, the gelation time-temperature curve is as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com