Mastic sealant and technical method thereof

A process method and technology of cement, which is applied in the field of sealing cement, can solve the problems of irregular joint surface, easy water seepage, inability to isolate air, etc., and achieve the effects of excellent sealing waterproof, good weather resistance and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below.

[0017] This embodiment provides a sealing cement, which is mainly used for waterproof sealing of cable joints in fields such as communication and electric power. Among them, the sealing glue is used as an auxiliary material, and it is often used in combination with cold-shrinkable tubes or tapes to optimize the waterproof and sealing performance of the cold-shrinkable tubes or tapes on the cable joints, and provide guarantee for safe and reliable transmission of signals and power.

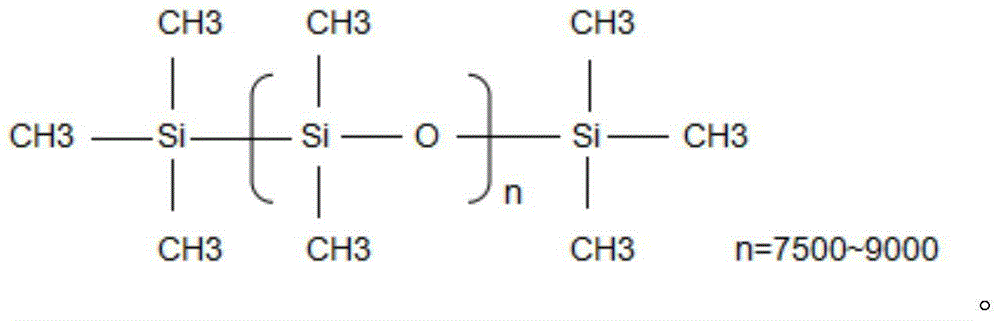

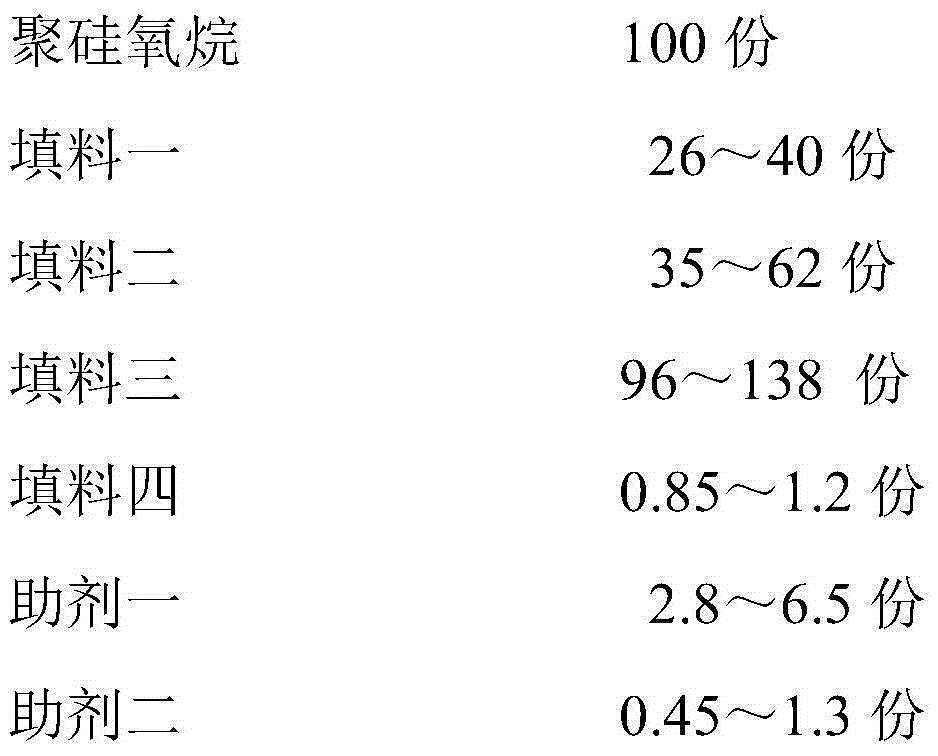

[0018] The sealing cement contains raw material components and parts as follows: 100 parts of polysiloxane, 26-40 parts of filler one, 35-62 parts of filler two, 96-138 parts of filler three, 0.85-1.2 parts of filler four, 2.8 parts of auxiliary agent one ~6.5 parts, auxiliary agent 2 0.45~1.3 parts; Among them, filler one is carbon black reinforcing agent, for example, filler one can be modified fumed silica, or hydrophobic precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com