Upper transverse beam and lower transverse beam construction method for bridge cable bent tower

A construction method and beam technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as inability to adapt to bridge span growth and tower height changes, high construction safety risks, and long support erection cycles, and achieve broad economic benefits and The effect of social benefits, improving construction quality and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

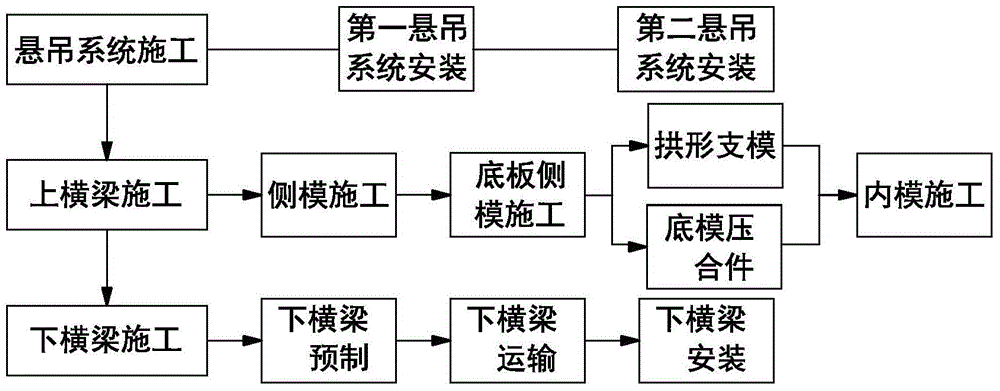

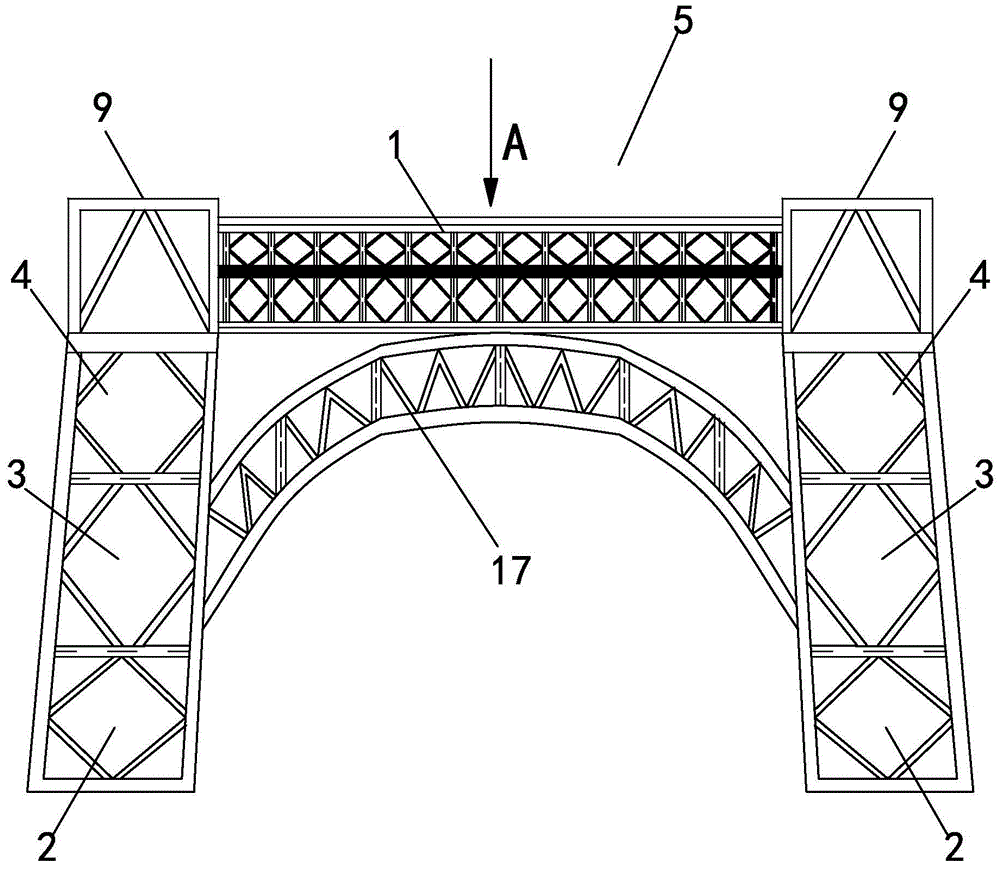

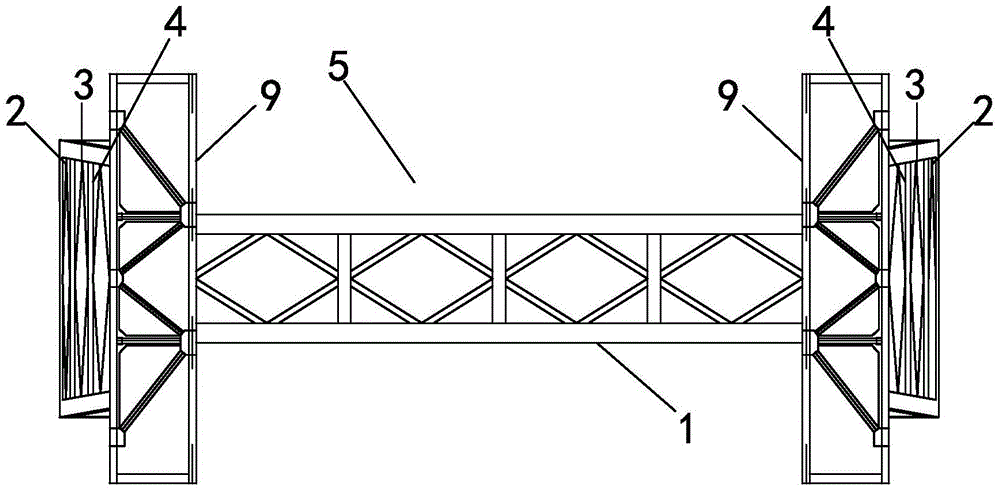

[0039]The invention relates to a construction method for the upper beam and the lower beam of a bridge cable tower. The lower beam 6 is 23.048m long, 13.5m high, and 7.5m wide; the upper beam 5 is 14.20m long, 8.5m high, and 3.5m wide. Before the official construction, first build the lifting system, set up the first lifting system on both sides of the cable tower, and then set up two sets of second lifting systems between the first lifting systems. The hoisting system and the second hoisting system can cooperate with each other or work independently. Then, carry out the construction of the upper beam 5, first build and pour the first section side form 2, the second section side form 3 and the third section side form 4, then build and pour the upper beam bottom form 1; after the upper beam 5 construction is completed , pouring the lower beam 6, the lower beam 6 is prefabricated, transported and installed through the lifting system, and finally connects the upper beam 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com