Staggered opposite jetting air film hole row structure used for turbine blade leading edge air film cooling

A turbine blade and air film cooling technology, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of difficulty in machining and poor heat insulation effect of inclined cylindrical hole rows in the same direction, and achieve low cost, The effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

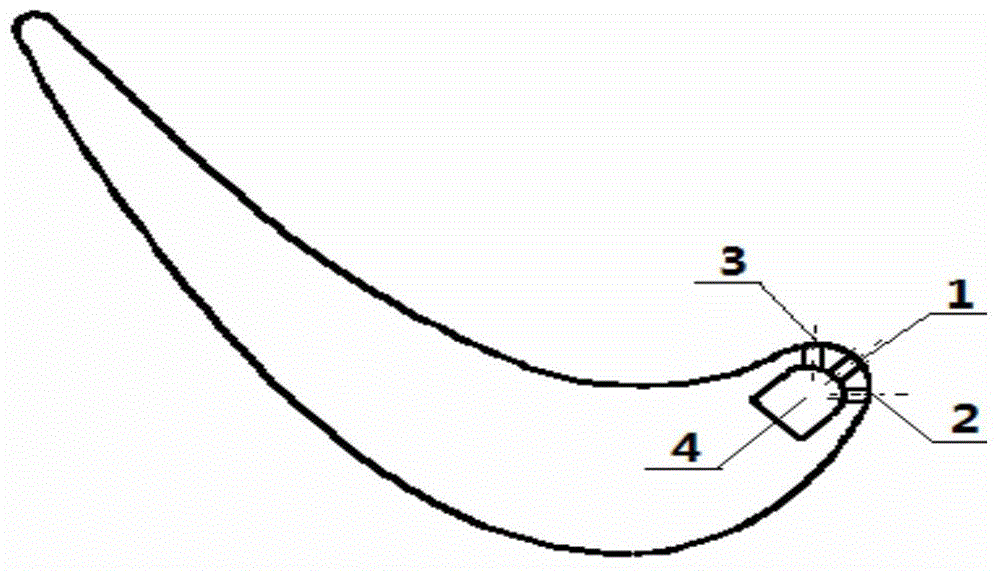

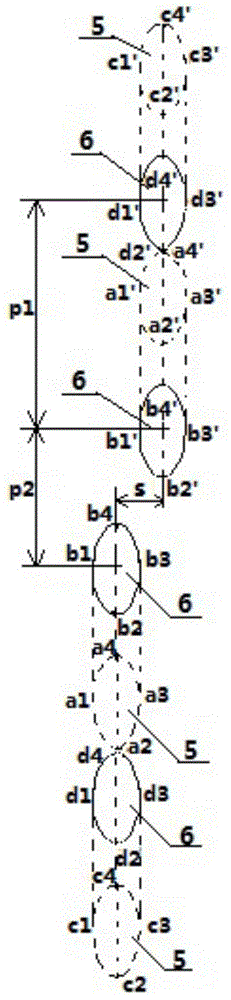

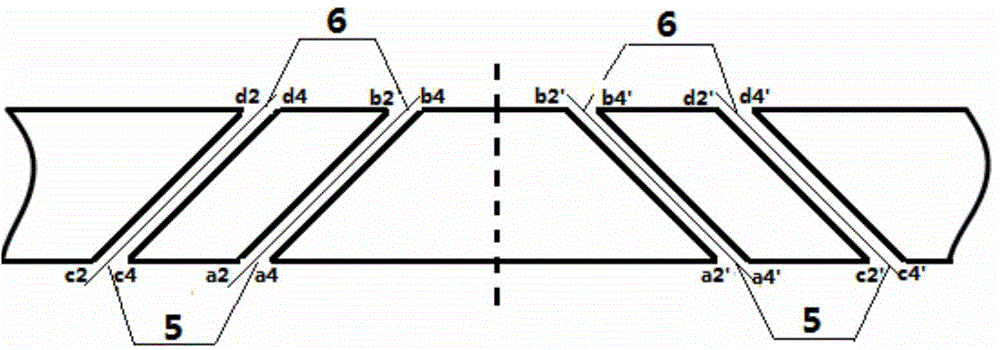

[0021] In this embodiment, the leading edge region of the turbine blade of a certain type of gas turbine is provided with a structure of dislocation opposing gas film holes. The opened air film hole is a cylindrical hole, and the cross-sectional shape of the air film hole changes from the entrance of the air film hole to the exit of the air film hole. The air film hole is inclined along the radial direction of the turbine blade. The inclination angles of half of the gas film holes are the same, but the inclination directions are opposite, and the center line of the upper half of the gas film holes and the center line of the lower half of the gas film holes are misaligned along the blade flow direction, forming a structure of dislocation pairs of punching holes.

[0022] The four vertices of the elliptical inlet of the film hole: a1, a2, a3, a4 correspond to the four vertices of the elliptical outlet: b1, b2, b3, b4, the side wall surface of the hole, including the surface a1-a2...

Embodiment 2

[0026] In this embodiment, the leading edge region of the turbine blade of a certain type of gas turbine is provided with a structure of dislocation opposing gas film holes. The air film holes opened are cylindrical holes, and the air film holes are inclined radially along the turbine blade. The inclination angles of the upper half of the air film holes and the lower half of the air film holes in the same row are the same, but the inclination direction is opposite, and the upper half The center line of part of the air film hole and the center line of the lower half of the air film hole are misaligned along the flow direction of the blade, forming a structure of misaligned pairs of punching holes.

[0027] The four vertices of the elliptical inlet of the film hole: a1, a2, a3, a4 correspond to the four vertices of the elliptical outlet: b1, b2, b3, b4, the side wall surface of the hole, including the surface a1-a2-b2-b1- a1, surface a1-a4-b4-b1-a1, surface a2-a3-b3-b2-a2, and s...

Embodiment 3

[0031] In this embodiment, the leading edge region of the turbine blade of a certain type of gas turbine is provided with a structure of dislocation opposing gas film holes. The air film holes opened are cylindrical holes, and the air film holes are inclined radially along the turbine blade. The inclination angles of the upper half of the air film holes and the lower half of the air film holes in the same row are the same, but the inclination direction is opposite, and the upper half The center line of part of the air film hole and the center line of the lower half of the air film hole are misaligned along the flow direction of the blade, forming a structure of misaligned pairs of punching holes.

[0032] The four vertices of the elliptical inlet of the film hole: a1, a2, a3, a4 correspond to the four vertices of the elliptical outlet: b1, b2, b3, b4, the side wall surface of the hole, including the surface a1-a2-b2-b1- a1, surface a1-a4-b4-b1-a1, surface a2-a3-b3-b2-a2, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com