Heating devices used for bearing protection of aerogenerator and bearing system

A technology for wind turbines and heating devices, which is applied to wind turbine components, wind engines, and wind power generation. It can solve problems such as fracture of bearing parts, loss of interference, and surface peeling, so as to achieve close contact and prolong service life. , maintain the effect of fluidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

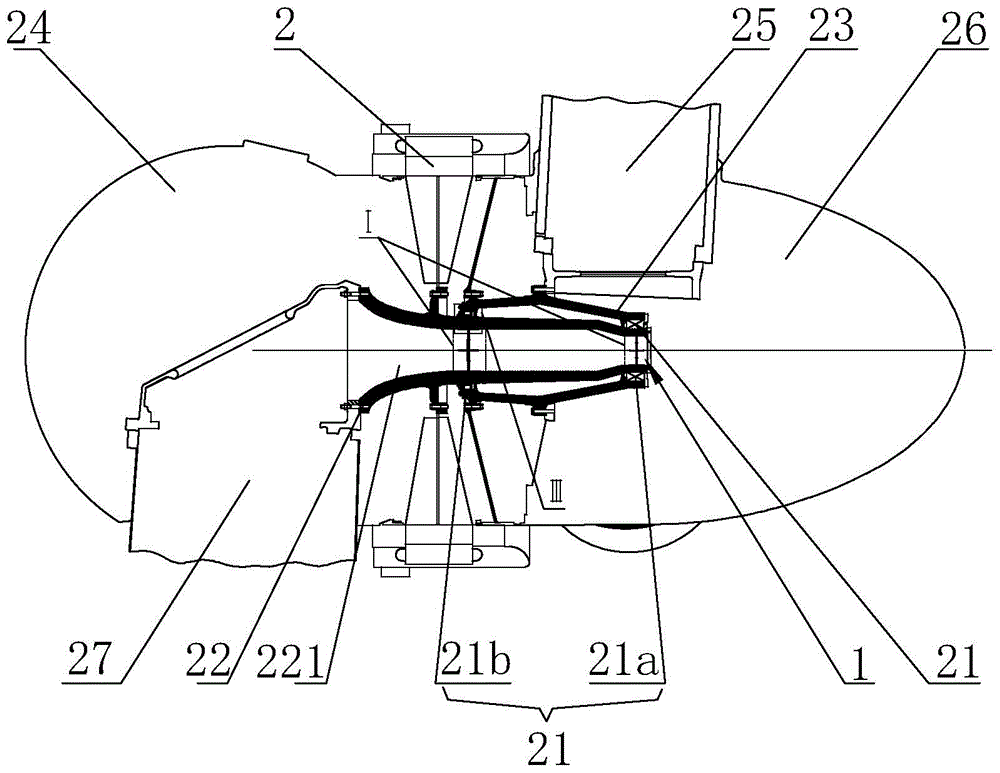

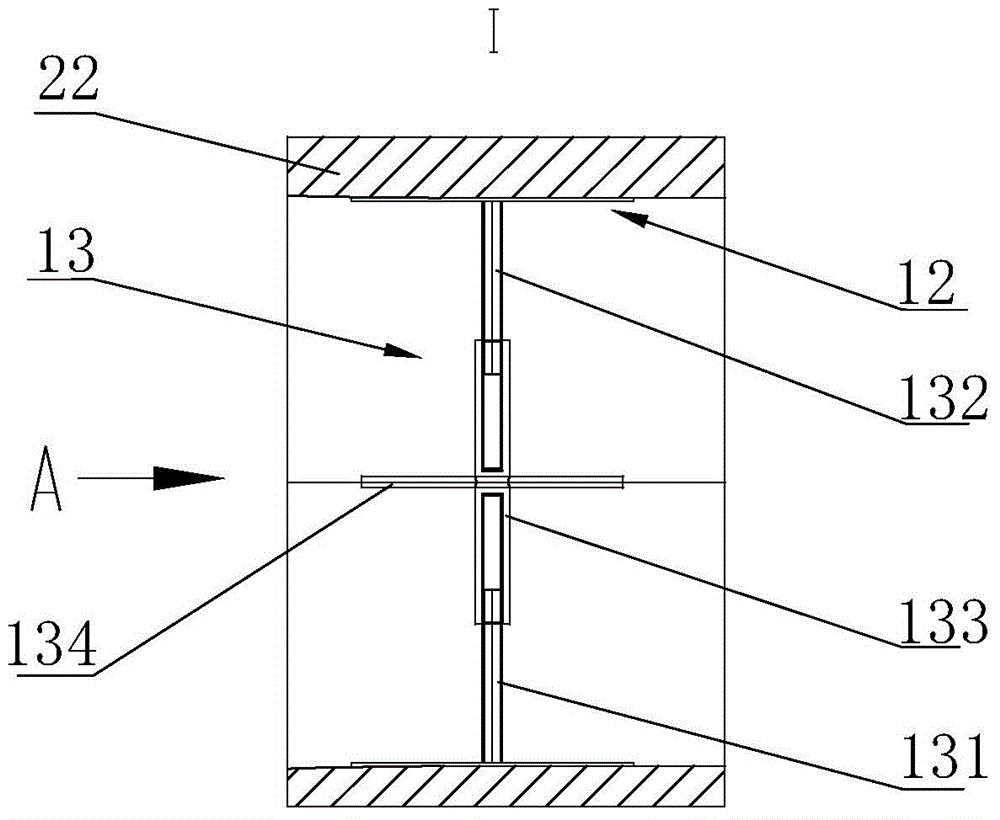

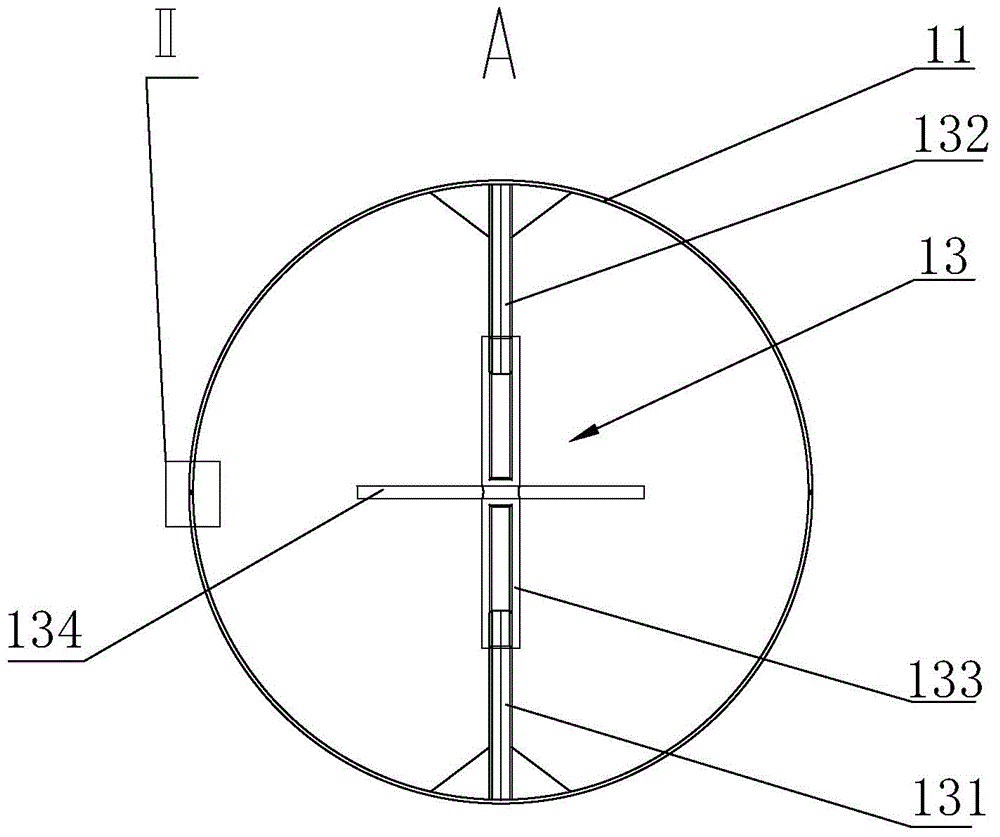

[0058] Such as Figure 1 to Figure 3 as shown, figure 1 It is a schematic diagram of the installation structure of the heating device in the embodiment of the present invention in the wind power generator, figure 2 for figure 1 Partial enlarged view of I in the structure shown, image 3 for figure 2 Front view of the structure shown at A.

[0059] The embodiment of the present invention provides a heating device 1 for bearing protection of a wind-driven generator, which can be applied to the main shaft of a wind-driven generator with bearings sleeved on the outside. The heating device 1 is placed inside the main shaft and passes through the inner wall of the main shaft. Heat the bearings that fit on the outside. In a wind turbine, both the stator and the rotor have their own main shafts. The main shaft of the stator is called the fixed shaft for short, and the main shaft of the rotor is called the moving shaft for short. According to the structure of the wind power gene...

Embodiment 2

[0073] refer to figure 1 , this embodiment relates to a bearing system of a wind power generator, mainly including the main shaft of the wind power generator and the paddle side bearing 21a and the tower side bearing 21b sleeved on the main shaft, inside the main shaft and with the paddle side bearing 21a and / or Or the heating device 1 described in the first embodiment above is provided at the position corresponding to the tower side bearing 21b.

[0074] Further, the above-mentioned wind power generator can have a structure of an outer rotor and an inner stator, then the main shaft is the fixed shaft of the wind power generator, and the moving shaft of the wind power generator is set on the fixed shaft through the tower side bearing and the paddle side bearing. outside of the shaft.

[0075] As another modification, the wind generator can also adopt the structure of the outer stator and the inner rotor, then the above-mentioned main shaft is the moving shaft of the wind gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com