Automatic flame failure device for dry burning of gas stove

A technology for automatic flameout and gas stoves, applied in the field of gas stoves, can solve problems such as loss of family property and the inability to automatically cut off gas stoves, and achieve the effects of shortening production time, protecting family property and personal safety, and avoiding dry burning fires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

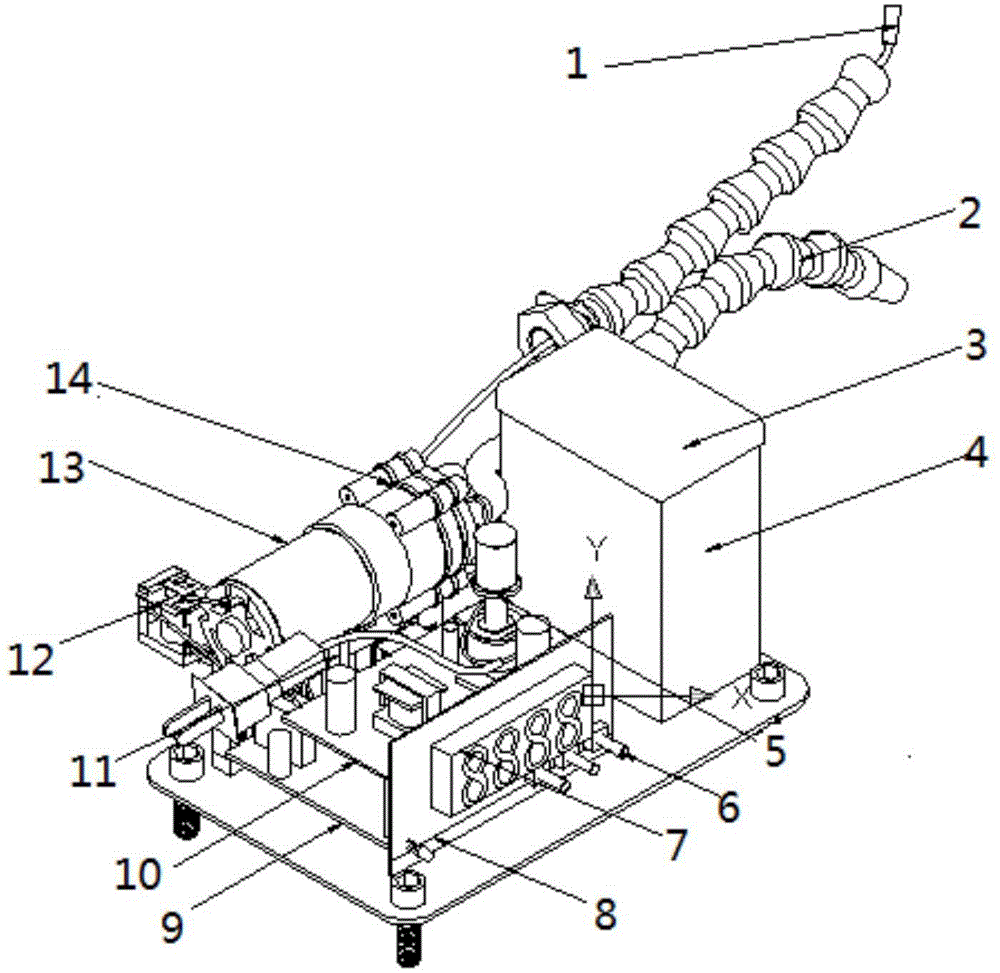

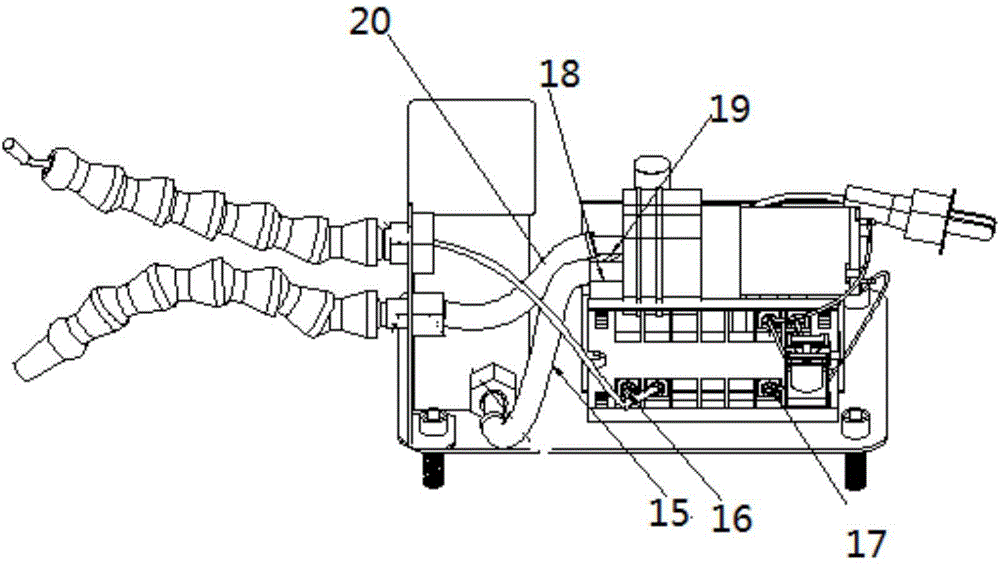

[0021] see Figure 1-Figure 2 , an automatic flame-out device for dry burning of a gas stove, including a control system and an execution system; the control system includes a temperature sensor 1 and a relay 12, and the temperature sensor 1 detects the temperature at the lower part of the pot in real time, and controls the switch of the relay 12 ; The execution system includes a cooling water tank 4, a servo motor 13, a pump body 14, a water pumping pipe 15, an outlet pipe 20, and a universal pipe 2, and the universal pipe 2 sprays water to the induction point of the gas stove thermocouple sensor to make it Cool down, then the intake valve of the gas cooker is closed, the gas supply is stopped and the flame is turned off; the control system receives the signal of excessive temperature fed back by the temperature sensor 1, the control relay 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com