A photosensitive dry film with high resolution and excellent hole-masking properties

A photosensitive dry film, high-resolution technology, applied in the field of photosensitive dry film, can solve the problems of limited resolution, low resolution, poor development of vinyl isocyanurate, etc., achieve high resolution, improve production efficiency, The effect of improving the masking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Alkali-soluble resin is the core component of the photosensitive composition. From the perspective of improving the pore-masking performance of the dry film, the molecular weight of the alkali-soluble resin should be increased; but from the perspective of dry film resolution, the molecular weight of the alkali-soluble resin needs to be controlled. In a certain range, based on this, the present invention utilizes the alkali-soluble resin prepared by living controllable free radical polymerization to effectively improve the The hole-masking performance of the dry film improves the yield of PCB production.

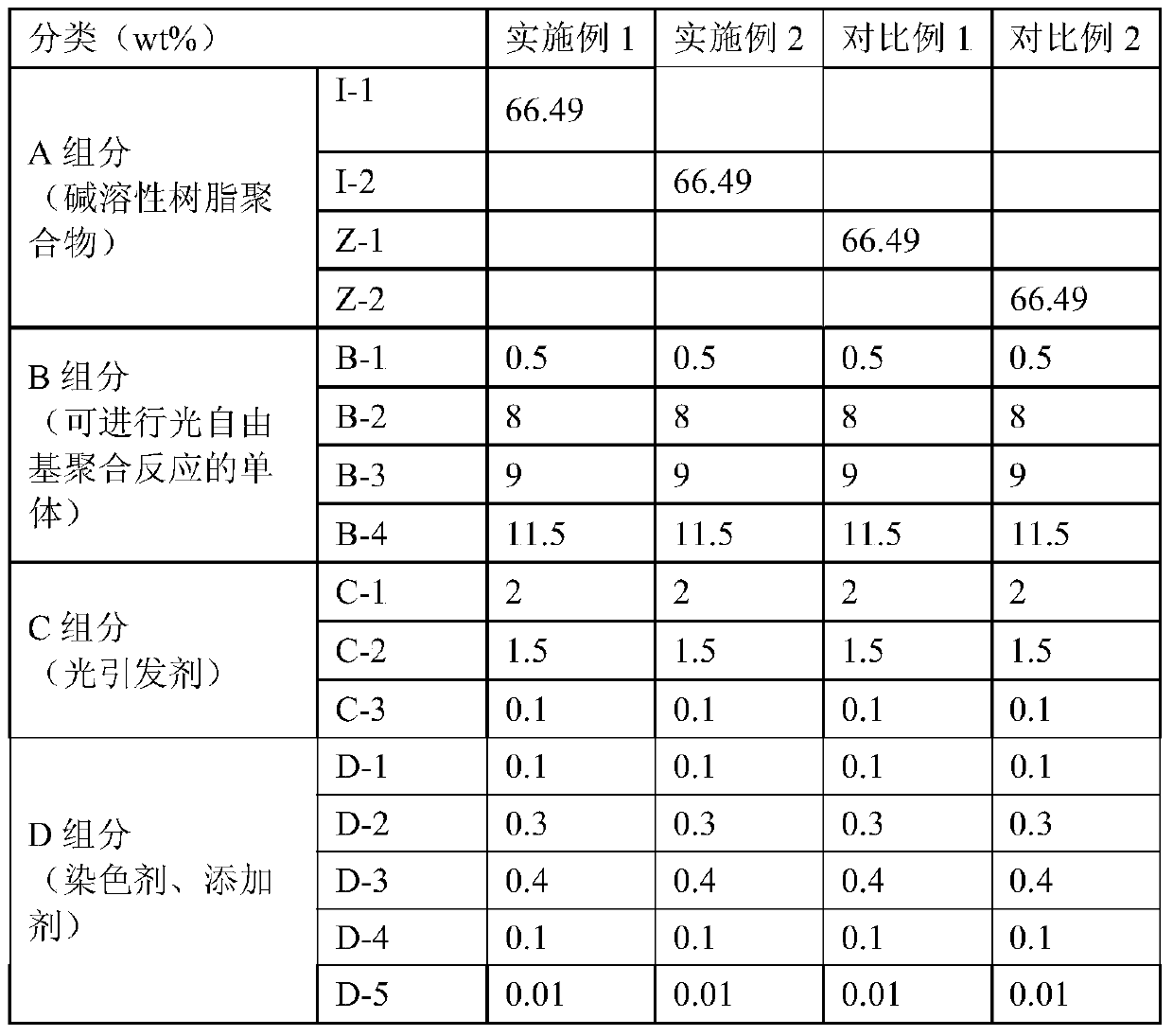

[0021] The invention discloses a photosensitive dry film, which sequentially comprises a polyester support layer, a photosensitive resin composition layer and a polyethylene protective layer. The photosensitive resin composition layer is used as the core layer of the dry film, and if it is set to be 100 weight ratio, it includes: (a) 50-70 weight parts of alkali-solubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com