Nonaqueous electrolyte secondary battery and method for manufacturing same

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte storage batteries, electrolyte storage battery manufacturing, secondary batteries and other directions, can solve the problems of not being able to miniaturize batteries, unable to form secondary batteries, etc., and achieve battery performance improvement, Excellent gravimetric energy density and effect of suppressing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136]

[0137] A laminate was assembled using the positive electrode I, the negative electrode, and the separator. Specifically, the above-mentioned positive electrode I and the negative electrode were laminated so that two separators were arranged between them to obtain a laminated body. After putting the laminated body into an aluminum laminate package, it was vacuum-dried at 80° C. for 2 hours with a vacuum dryer. Next, an electrolytic solution is injected into the vacuum-dried package. As the electrolytic solution, an electrolytic solution obtained by adding vinylene carbonate (VC) as an electrolytic solution additive in a ratio of 2 parts by weight to 100 parts by weight of the electrolytic solution i prepared above was used. Finally, the package was sealed to obtain the non-aqueous electrolyte secondary battery of Example 1. In addition, the injection into the package was performed in a glove box under an ultra-high-purity argon atmosphere. The dew point in the glo...

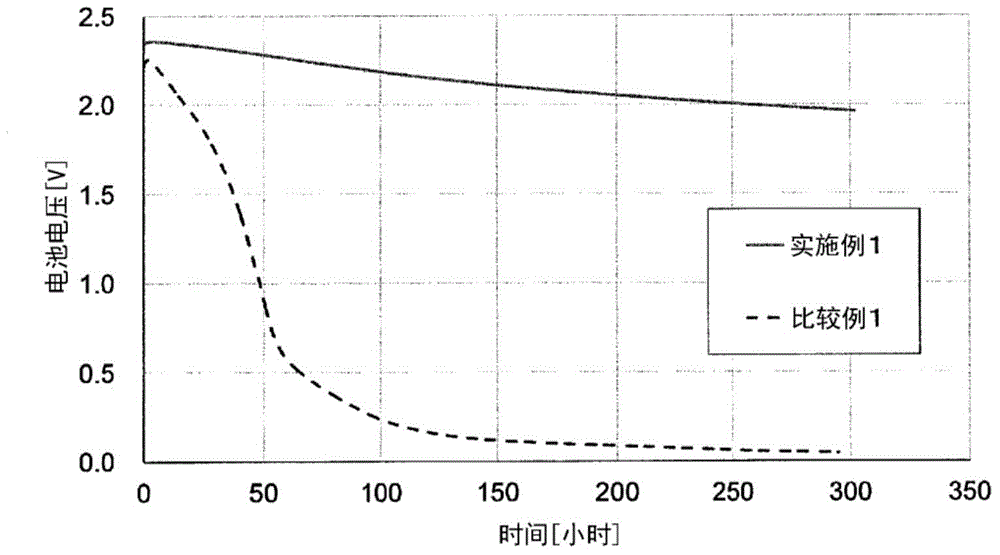

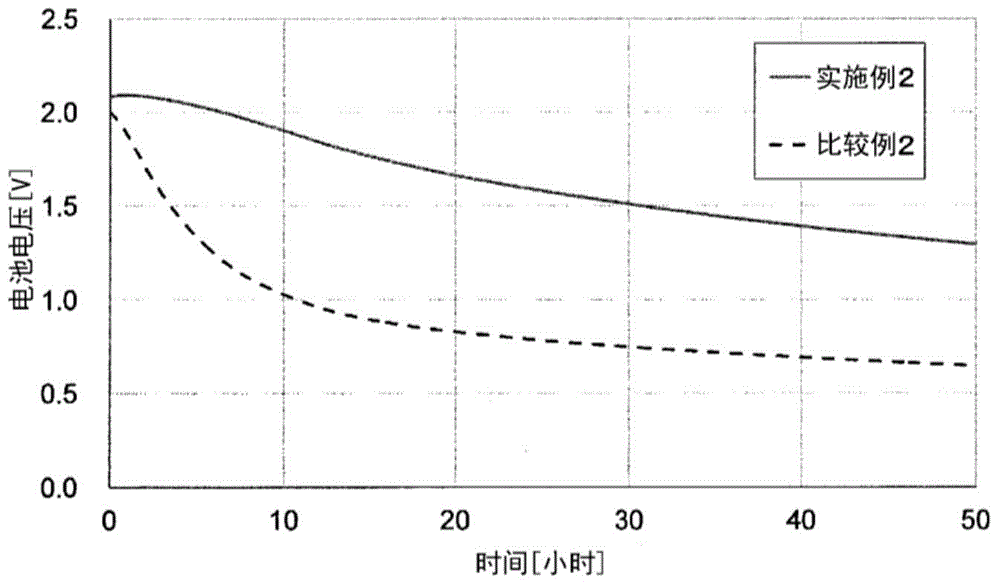

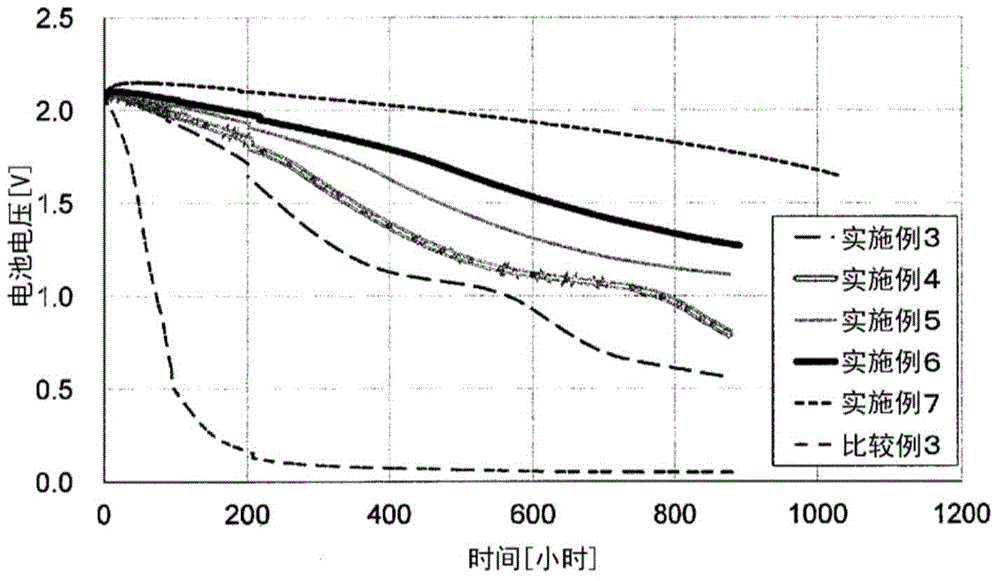

Embodiment 2~16、 comparative example 1~5

[0139] The positive electrode, the electrolytic solution, the type of additive for the electrolytic solution, and the additive amount of the additive for the electrolytic solution (negative electrode film-forming agent) were substituted as shown in Tables 1 to 5 described later. Except for this, a laminated battery (nonaqueous electrolyte secondary battery) was fabricated in the same manner as in Example 1.

[0140] The gravimetric energy density was measured according to the following reference|standard about the nonaqueous electrolyte solution secondary battery of the Example and the comparative example obtained in this way. The results are collectively shown in Tables 1 to 5 described later.

[0141] "Determination of gravimetric energy density"

[0142] The non-aqueous electrolyte secondary battery was placed in a constant temperature bath at 25° C., and the measurement was performed in a constant current-constant voltage charge / constant current discharge mode using a bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com