Material mixing method and device, manufacturing method of soft-elastic container in device and material mixing method based on device

A technology for mixing elastic containers and materials, applied in the direction of mixing methods, fluid mixers, mixers, etc., can solve the problems of being unable to be applied in large-scale actual production, and achieve market promotion, simple manufacturing methods, and low material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

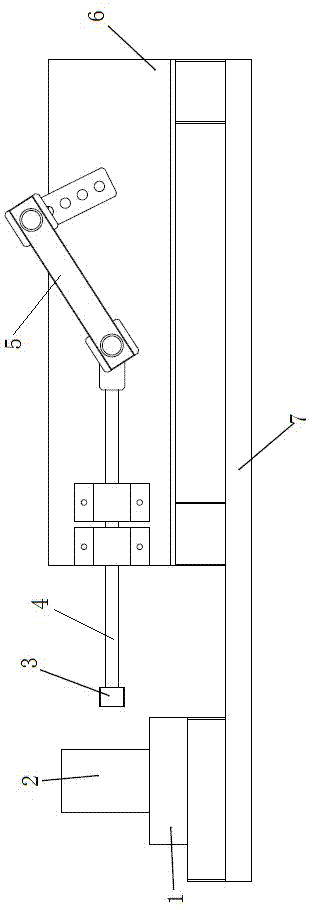

[0067] Method and mixing experiment for manufacturing soft elastic container (1)

[0068] (1) Prepare the mold: Prepare two semicircular plexiglass tubes (outer diameter 7cm, inner diameter 6cm, height 25cm), prepare a hollow plexiglass tube (outer diameter 5cm, inner diameter 4cm, height 30cm) as the inner tube, use Clamps (7cm in diameter) fix the two semicircular tubes as the outer tube, and then fix the inner tube and the outer tube with screws respectively. The bottom of the inner tube is higher than the bottom of the outer tube, and the bottom of the inner tube and the outer tube are sealed with glass plates ;

[0069] (2) Preparation of soft elastic container: Mix liquid silica gel and cross-linking agent at a mass ratio of 10:1, defoam, inject into the mold obtained in step (1), and cure for 24 hours to obtain a soft elastic container. The outer diameter is 6cm, the inner diameter is 5cm, the height is 12cm, the tensile strength (kgf / c㎡) of the soft elastic contai...

Embodiment 2

[0074] Method and mixing experiment for manufacturing soft elastic container (2)

[0075] Step (1)~step (3) is identical with embodiment 1;

[0076] (4) Insert a baffle in the middle of the soft elastic container;

[0077] (5) Same as step (4) in Example 1;

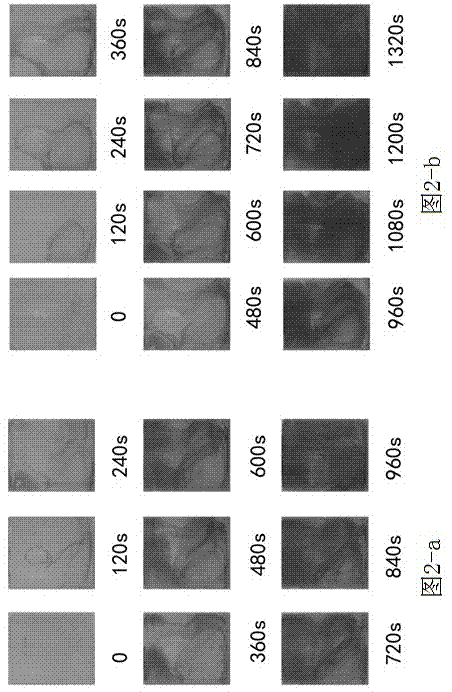

[0078] (6) Mixing effect (see attached figure 2 ): After adding the T-shaped baffle, the uniformity of the overall flow of the fluid increased, and no characteristic flow was found. After 60s, half of the reactor was covered with red, and an irregular oval appeared in the middle of the two baffles Flow, the fluid in the container can achieve a good mixing effect after 300s. After adding the baffle, the mixing efficiency of the soft elastic container is greatly improved, but a small bad mixing area appears in the lower left corner of the soft elastic container.

Embodiment 3

[0080] Method and mixing experiment for manufacturing soft elastic container (3)

[0081] Step (1)~step (3) is identical with embodiment 1;

[0082] (4) Adjust the motor frequency to 100 times / minute;

[0083] (5) Same as step (4) in Example 1;

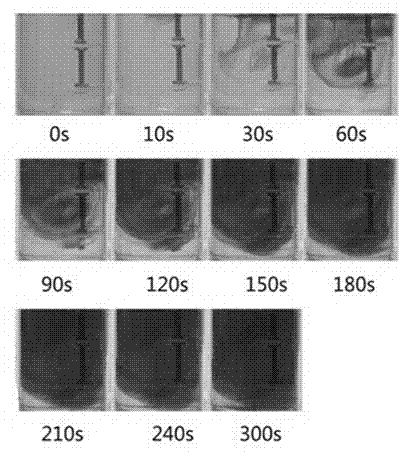

[0084] (6) Mixing effect (see attached Figure 4 ): Under high-frequency extrusion, the flow velocity of the fluid in the soft elastic container increases as a whole, and the flow details become difficult to capture. At 15s, a part of the fluid can be observed flowing from top to bottom, and at 30s, the upper part of the soft elastic container appears Some irregular flow, an irregular annular flow appeared in the middle of the soft elastic container to the right, no obvious mixing was found in the left half, from 90s to 210s, the fluid expanded to the left and the lower part, 240s achieves a good mix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com